Checkout Latest News and Articles

Motor lamination materials determine magnetic performance, iron loss, efficiency, noise, heat dissipation, and ultimately the cost and reliability of the motor.

Read Article

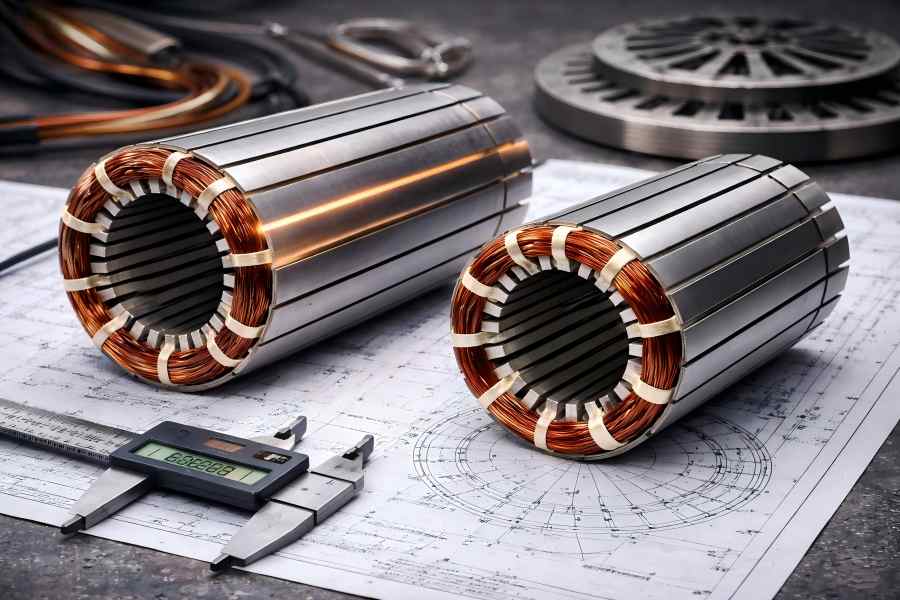

Motor lamination stacking is a critical process in electric motor and generator manufacturing, directly influencing efficiency, magnetic performance, mechanical strength, and production cost.

Read Article

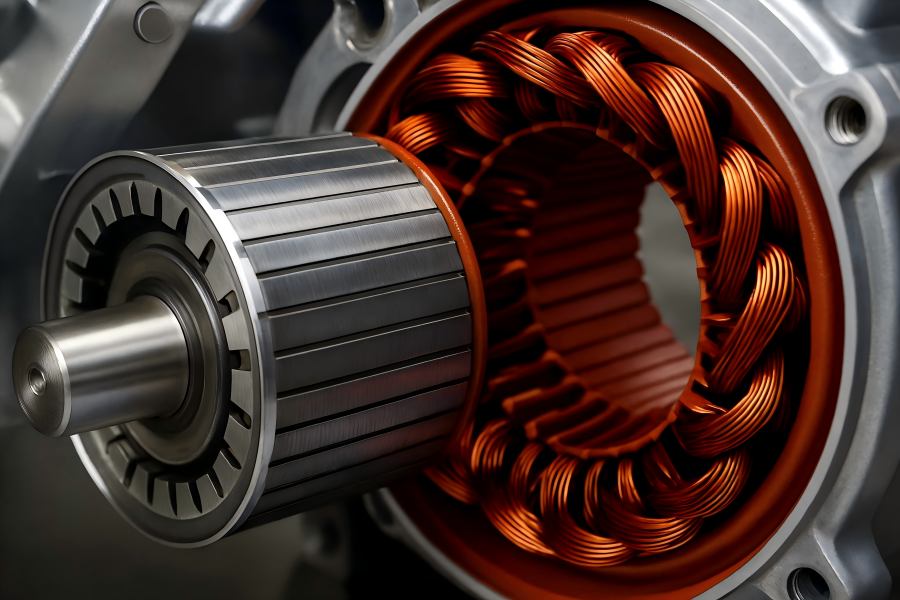

In electric motor engineering, for engineers involved in motor design, manufacturing, testing, or system integration, misunderstanding these components can lead to specification errors, efficiency losses, or incorrect fault diagnosis.

Read Article

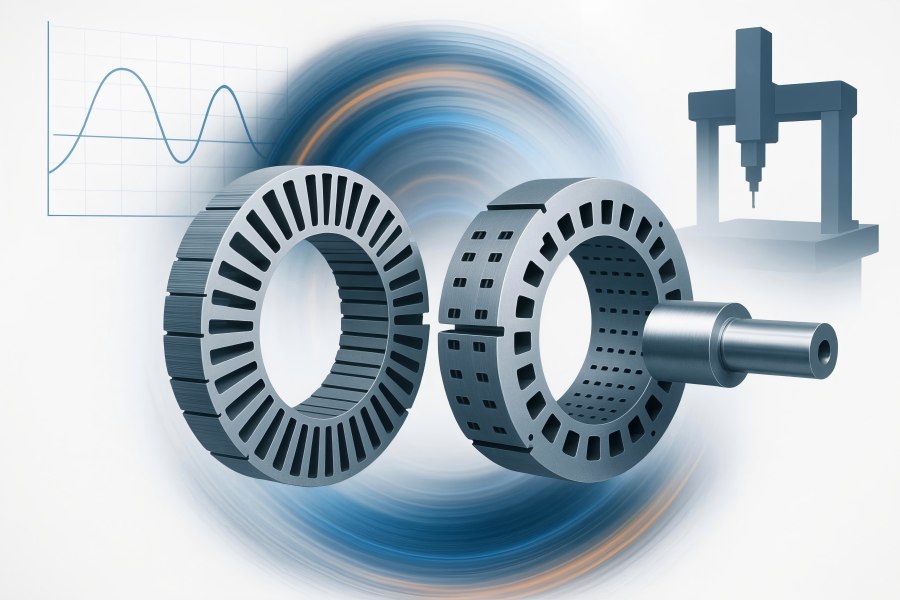

Beyond electromagnetic design and control strategies, the stator and rotor stacking process plays a crucial yet often overlooked role in influencing motor noise and vibration.

Read Article

Motor stack length is a key factor that impacts both the performance and efficiency of electric motors. It is essential in determining torque, speed, and energy usage. By understanding stack length, engineers can optimize motor designs to meet specific application needs, improving both efficiency and performance.

Read Article

when a stator core lamination develops a short circuit, it can significantly impact the motor’s performance, leading to efficiency losses, increased wear, and potential failure.

Read Article

Choosing the right rotor core for a servo motor is essential to achieving optimal performance, efficiency, and longevity. Key factors such as material, geometry, and manufacturing method all influence the motor’s operation.

Read Article

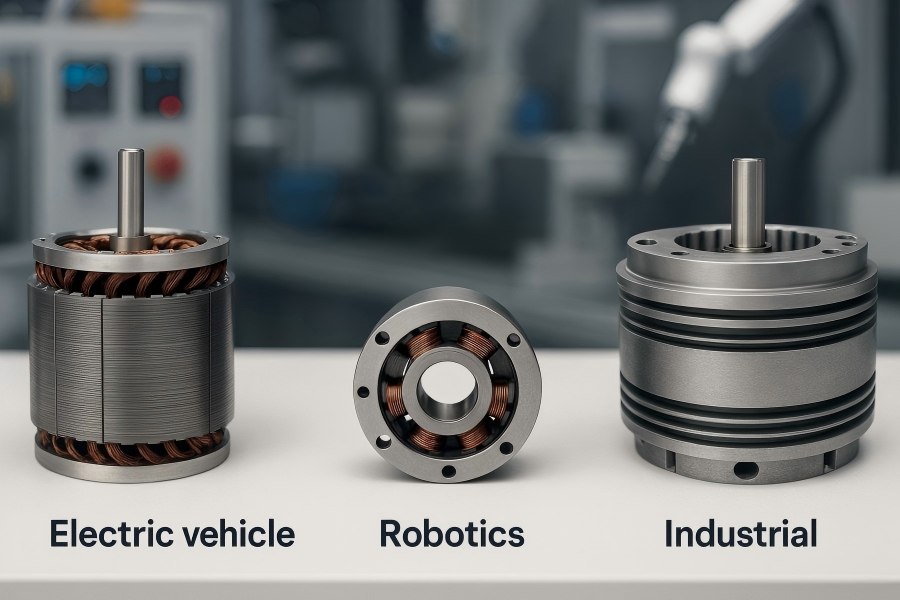

Electric vehicles, collaborative robots, and industrial drives are reshaping modern industry, and all depend on high-performance electric motors. At the core of these motors are stator and rotor lamination stacks, which define efficiency, torque, speed capability, thermal performance, and long-term reliability.

Read Article

High-speed motors power demanding applications like EVs, compressors, spindles, and aerospace equipment, where small weaknesses in stator and rotor cores can cause loss, overheating, vibration, or failure. In these designs, material selection, lamination thickness, structure, and manufacturing precision directly determine electromagnetic performance, mechanical strength, noise, and efficiency.

Read Article

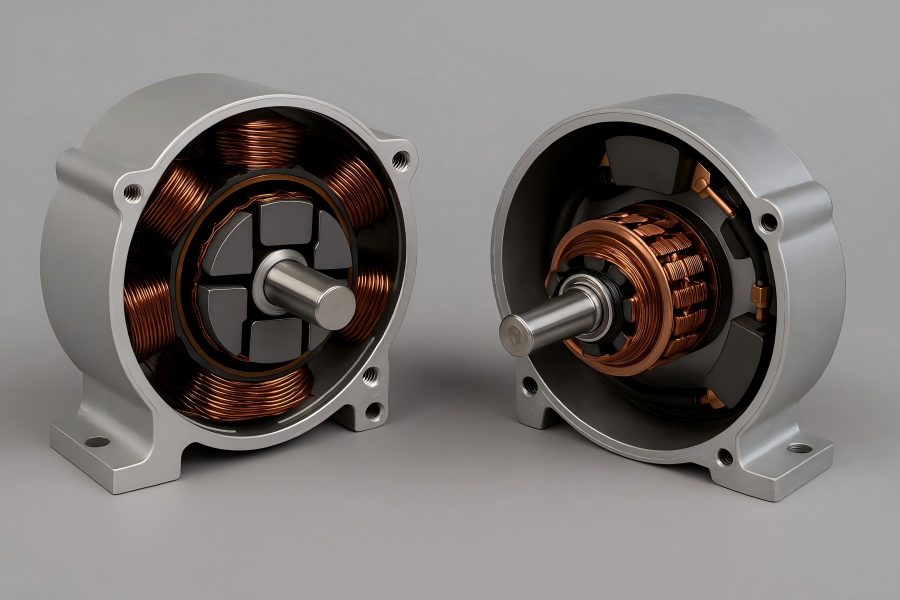

The two main types — die-cast (squirrel cage) and wound rotor — each offer distinct structures, advantages, and application scopes. Selecting the right one requires balancing performance, maintenance, cost, and control needs.

Read Article

The brushed motor’s simplicity, with a wound armature and mechanical commutation, offers low-cost torque at the expense of maintenance and efficiency. The BLDC motor, with its permanent-magnet rotor and electronically controlled stator, achieves higher performance, lower wear, and superior thermal management—perfect for modern, digitally controlled systems.

Read Article

The generator stator and rotor are far more than mechanical parts—they are the beating heart of power generation. Their seamless interaction embodies the very essence of energy conversion, bridging the physical motion of machines with the invisible flow of electrons that power the world.

Read Article