DC motors are crucial for a variety of applications in today’s consumer electronics and industrial sectors, including HVAC systems and electric cars. One common problem that jeopardizes their performance and safety is abnormal motor core speed. Electrical, mechanical, or environmental factors might cause this problem, which is frequently disregarded.

Finding the underlying reasons and implementing the appropriate fixes are essential to guaranteeing dependable and durable performance.

Understanding the DC Motor Core and Its Function

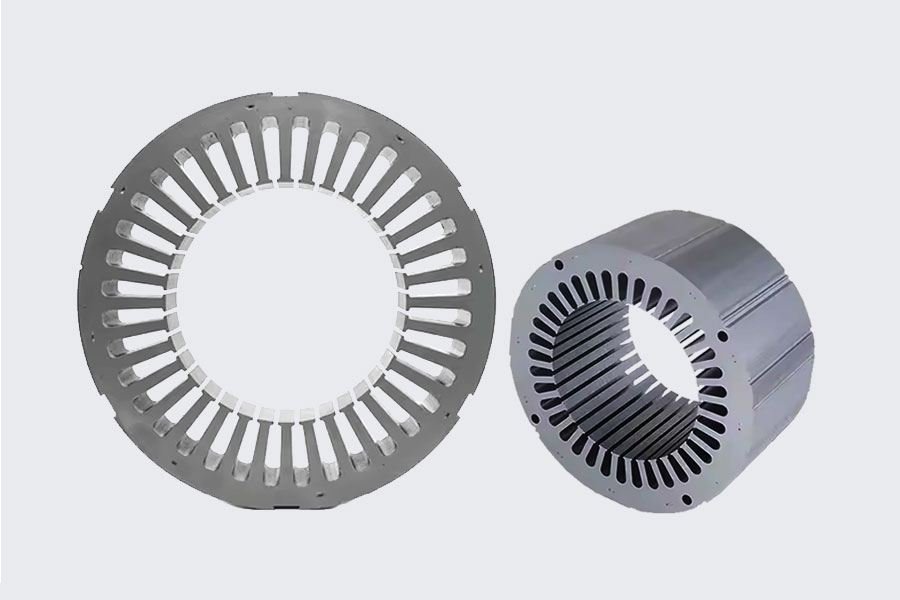

At the heart of every DC motor lies the core, usually made up of laminated silicon steel sheets to reduce eddy current losses. The motor core plays a pivotal role in creating the magnetic field necessary for torque generation. In brushed DC motors, the armature (rotor) core rotates inside a stationary stator field. In brushless designs, the roles are reversed or electronically commutated. Regardless of configuration, if the core is not functioning properly, abnormalities in motor speed are likely to follow.

Abnormal speed in DC motor cores generally refers to speed that is either unexpectedly high, unusually low, fluctuates erratically, or uis nstable under constant load and voltage. While it may initially seem to be a superficial anomaly, it can be an indicator of deeper issues in motor operation, control system feedback, or internal wear and tear.

Common Causes of Abnormal Speed in DC Motor Cores

Voltage Fluctuations or Inconsistent Power Supply

A DC motor’s speed and applied voltage are directly correlated. Any sudden dips or surges in supply voltage can cause the motor speed to deviate from its expected range. Overvoltage conditions may drive the motor excessively fast, increasing wear and reducing lifespan, while undervoltage can cause the motor to stall or struggle under load.

Worn Brushes and Commutators

In brushed DC motors, brushes transfer current to the rotating armature via a commutator. Over time, these brushes wear down or develop carbon deposits that lead to poor electrical contact, resulting in erratic speed, arcing, and voltage drops. A damaged commutator surface can further intensify the issue by increasing electrical resistance.

Armature Winding Faults

Winding short circuits, open circuits, or insulation degradation in the armature can drastically impact the magnetic field strength and uniformity, leading to speed inconsistencies. These internal faults are not always externally visible and often require detailed motor testing to diagnose.

Controller Malfunction or Feedback Loop Errors

DC motors, especially brushless types, often rely on a controller with a feedback mechanism (typically using encoders or Hall sensors) to regulate speed. Faulty sensors or corrupted firmware can distort the feedback signal, causing the controller to miscalculate speed requirements and apply incorrect voltages.

Excessive Load or Mechanical Binding

An overloaded motor or one operating in a jammed or partially obstructed condition will experience resistance to rotation. This directly lowers speed and increases current draw. Friction in bearings or misalignment in the coupling can also contribute to these abnormal speed conditions.

Magnet Degradation

In permanent magnet DC motors, magnet strength is a crucial factor. Overheating, physical damage, or long-term demagnetization reduces the field strength, affecting back EMF (electromotive force) and disturbing speed control. In settings where temperature swings are significant, this is particularly important.

Environmental Factors

Moisture, dust, and temperature extremes can deteriorate insulation, promote corrosion, or cause condensation within the motor housing. These conditions can lead to short circuits, arcing, or increased internal resistance, resulting in erratic speed behavior.

Diagnosing Abnormal Speed in DC Motors

To address abnormal speed issues effectively, a systematic diagnostic approach is essential:

- Measure Input Voltage and Current Draw: Use multimeters and oscilloscopes to ensure the power supply is stable and within manufacturer-recommended values.

- Visual Inspection: Check for brush wear, commutator burns, or loose connections. For brushless motors, inspect sensors and wiring integrity.

- Rotor Balance and Alignment Tests: An imbalanced rotor can cause vibration and speed fluctuation. Check for shaft misalignment or bent components.

- Motor Analyzer Tests: Modern motor analyzers can assess winding resistance, insulation integrity, and back EMF to detect internal faults quickly.

- Controller Firmware Update and Calibration: Reinstall or update the controller firmware, recalibrate the sensors, and run diagnostic routines to ensure accurate speed control.

Effective Remedies for Speed Abnormalities

Once the root cause is identified, the appropriate remedy must be implemented promptly to avoid long-term damage.

Stabilize the Power Supply

Install voltage regulators or uninterruptible power supplies (UPS) for sensitive applications. Using filters and surge protectors can also help mitigate transient spikes and harmonics.

Replace Worn Brushes and Service Commutators

Regular maintenance should include replacing carbon brushes before they reach end-of-life. Commutator surfaces should be cleaned or turned on a lathe if excessively worn or grooved.

Repair or Rewind Faulty Windings

For motors with compromised windings, rewinding or replacing the core may be necessary. This requires skilled technicians and should adhere to the original specifications.

Upgrade or Reprogram Motor Controllers

Modern controllers offer advanced fault detection and compensation features. Ensure compatibility between the motor and controller, and reprogram control logic where required.

Lubricate Bearings and Correct Mechanical Misalignments

Use manufacturer-recommended lubricants and ensure shafts and couplings are precisely aligned. Replace worn bearings to eliminate internal drag and friction.

Replace Degraded Magnets

In cases of permanent magnet demagnetization, replacing the rotor or remagnetizing the core (if possible) is essential to restore proper field strength.

Protect the Motor from Harsh Environments

Enclose motors in protective housings, use IP-rated enclosures, and add thermal sensors to monitor temperature. Humidity control and dehumidifiers can help in high-moisture regions.

Preventive Maintenance Strategies

Avoiding abnormal speed issues begins with a robust preventive maintenance program. Key elements include:

- Scheduled Inspections: Periodically check motor components and controllers to detect early signs of wear or failure.

- Performance Monitoring: Use condition monitoring systems that track temperature, vibration, and speed in real-time.

- Record Keeping: Maintain logs of motor performance, repairs, and inspections. This helps spot recurring trends or component weaknesses.

- Training Operators: Educate technical staff on early symptoms of speed irregularities and encourage prompt reporting.

Industry Examples and Case Studies

Electric Vehicles

DC motor speed control is critical in electric vehicles for acceleration, regenerative braking, and energy efficiency. An automotive supplier experienced sporadic overspeeding in its traction motors. Investigation revealed sensor misalignment after chassis vibration. Realigning and securing sensors restored normal operation.

HVAC Systems

In industrial air handling units, brushless DC fans started displaying inconsistent airflows. A deeper inspection pointed to aging controller firmware that failed to compensate for voltage drops. A firmware update and capacitor upgrade in the controller resolved the issue.

Medical Equipment

DC micromotors in infusion pumps began fluctuating unpredictably during operation. The culprit was corrosion buildup on motor brushes due to sterilization humidity. Switching to sealed brushless motors eliminated the problem and enhanced reliability.

Looking Ahead: Trends in DC Motor Speed Control

As industries shift toward automation and energy efficiency, the need for tighter control over motor behavior, including speed accuracy, is paramount. Innovations like AI-based predictive maintenance, sensor fusion, and smarter embedded motor drivers will become standard. Motor cores may also evolve, with newer materials like amorphous metals and soft magnetic composites reducing losses and improving thermal resilience.

Manufacturers are also beginning to design motors with self-diagnostic capabilities, alerting users to early signs of abnormal speed or internal faults before catastrophic failure occurs. As these technologies mature, the traditional concept of “preventive maintenance” may shift toward predictive and even autonomous maintenance.