Checkout Latest News and Articles

Progressive high-speed stamping is a critical manufacturing process for motor laminations, impacting part quality, throughput, and overall production cost.

Read Article

Motor lamination stamping directly affects magnetic performance, efficiency, and reliability in electric motors used across EV, industrial, appliance, and renewable energy applications.

Read Article

Electric motors and generators power modern equipment across industries, transportation, and energy systems. The motor lamination steel grade used in the core plays a critical role in efficiency, loss reduction, and long-term reliability.

Read Article

Motor lamination materials determine magnetic performance, iron loss, efficiency, noise, heat dissipation, and ultimately the cost and reliability of the motor.

Read Article

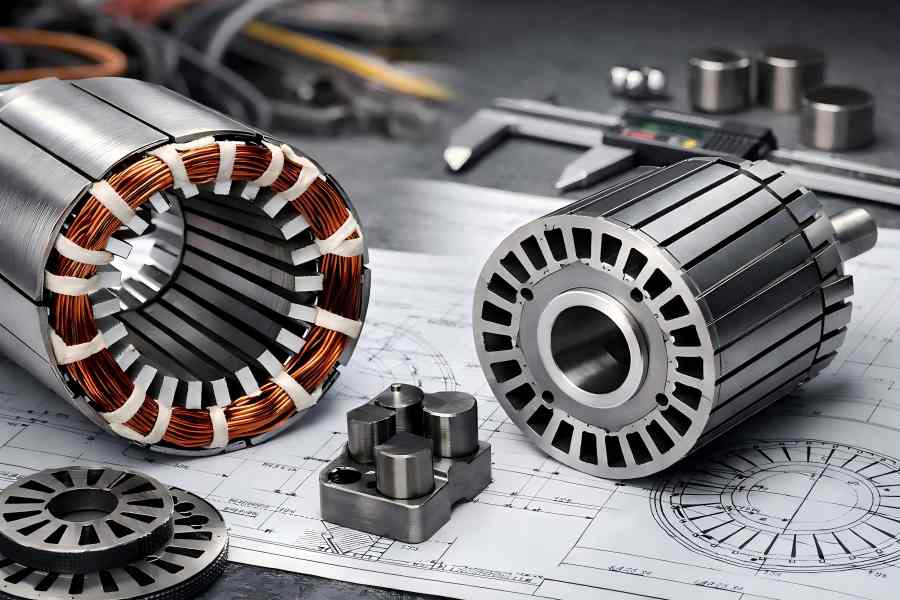

Motor lamination stacking is a critical process in electric motor and generator manufacturing, directly influencing efficiency, magnetic performance, mechanical strength, and production cost.

Read Article

In electric motor engineering, for engineers involved in motor design, manufacturing, testing, or system integration, misunderstanding these components can lead to specification errors, efficiency losses, or incorrect fault diagnosis.

Read Article

Beyond electromagnetic design and control strategies, the stator and rotor stacking process plays a crucial yet often overlooked role in influencing motor noise and vibration.

Read Article

As electric motors advance toward higher efficiency, compact designs, and mass production, lamination stacking has become critical to both performance and cost. Self-locking stator and rotor stacks are popular because they are easy to use, dependable, and appropriate for large-scale production.

Read Article

Motor stack length is a key factor that impacts both the performance and efficiency of electric motors. It is essential in determining torque, speed, and energy usage. By understanding stack length, engineers can optimize motor designs to meet specific application needs, improving both efficiency and performance.

Read Article

when a stator core lamination develops a short circuit, it can significantly impact the motor’s performance, leading to efficiency losses, increased wear, and potential failure.

Read Article

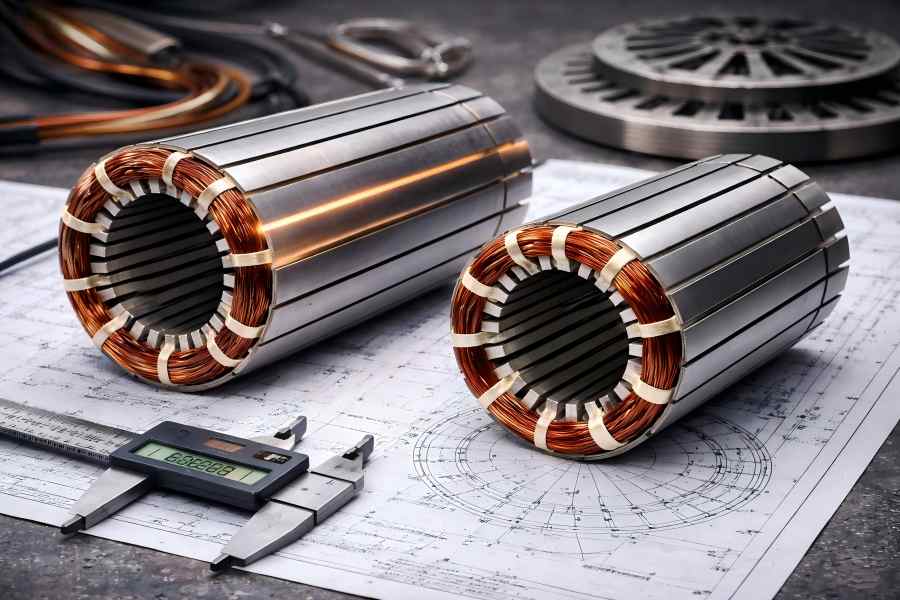

Motor lamination stacks form the magnetic backbone of electric motors, guiding magnetic flux efficiently and minimizing energy losses from eddy currents and hysteresis. By using thin, insulated steel sheets instead of a solid iron core, motors achieve higher efficiency, lower operating temperatures, and longer service life.

Read Article

Motor laminations, an integral part of electric motors, are vital for their performance, efficiency, and durability. By reducing energy losses such as eddy currents and improving the motor’s magnetic properties, the materials used in motor laminations significantly influence motor efficiency.

Read Article