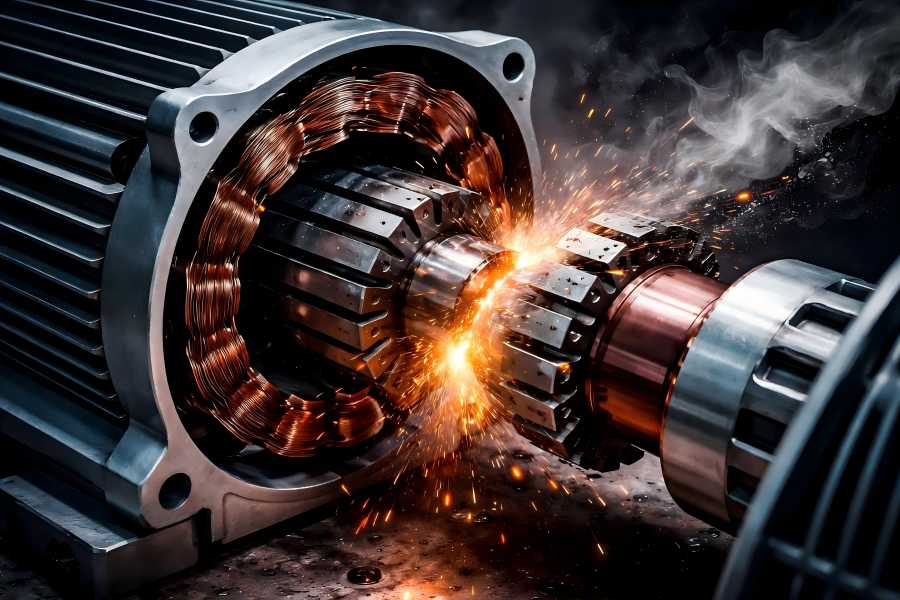

How Flywheel Rotor and Stator Designs Impact Power Generation in Industrial Applications

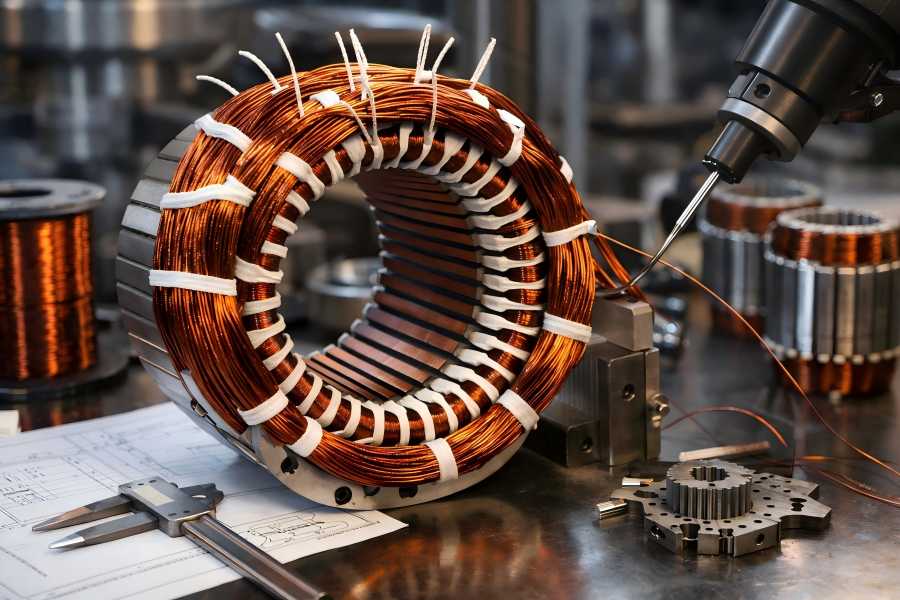

Flywheels are crucial components in energy storage systems, acting as mechanical batteries to store and release energy in industrial applications. The rotor and stator components’ designs have a significant impact on these systems’ efficiency.