Checkout Latest News and Articles

Laser cutting sample making capabilities are playing a transformative role, especially in the prototyping and customization of motor laminations.

Read Article

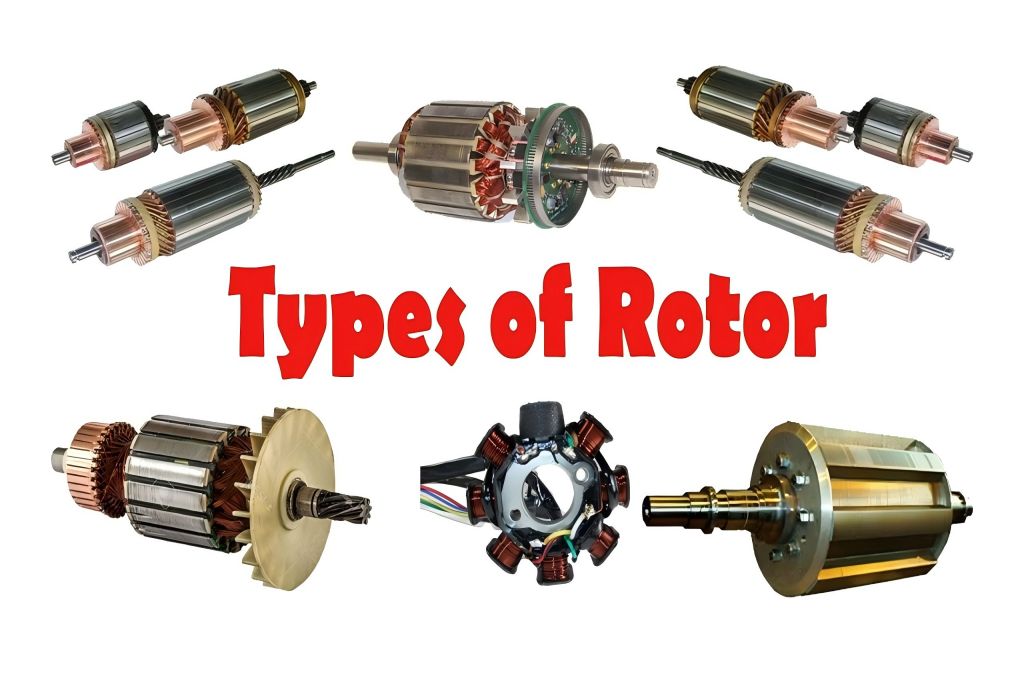

Electric motors are essential in modern technology, and at the heart of every motor is its rotor. An essential component in the transformation of electrical energy into mechanical motion is the rotor. Motor rotors come in a variety of forms, each intended for a particular use and guaranteeing maximum effectiveness, longevity, and performance.

Read Article

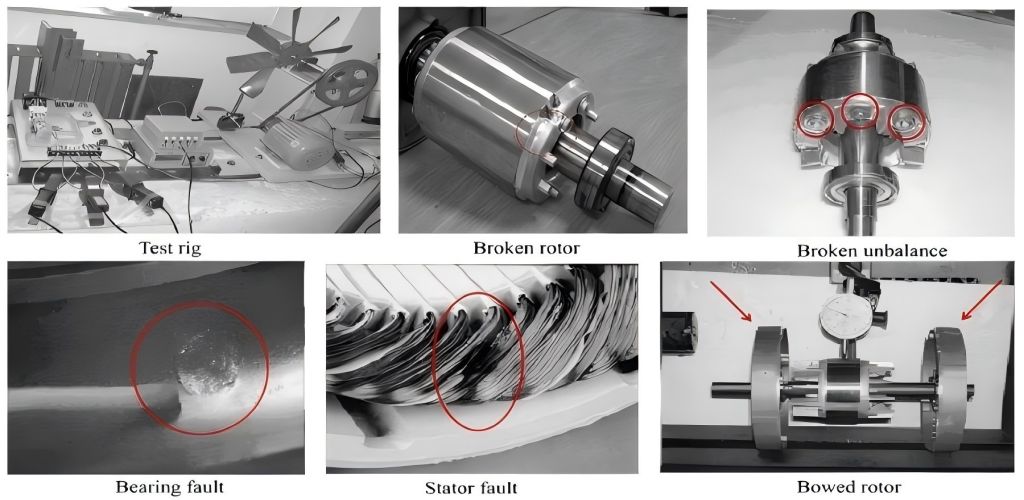

Motor stators, the stationary component that produces the electromagnetic field required for rotation, are crucial parts of electric motors. They are, nevertheless, also vulnerable to a number of problems that may affect the longevity and performance of the motor.

Read Article

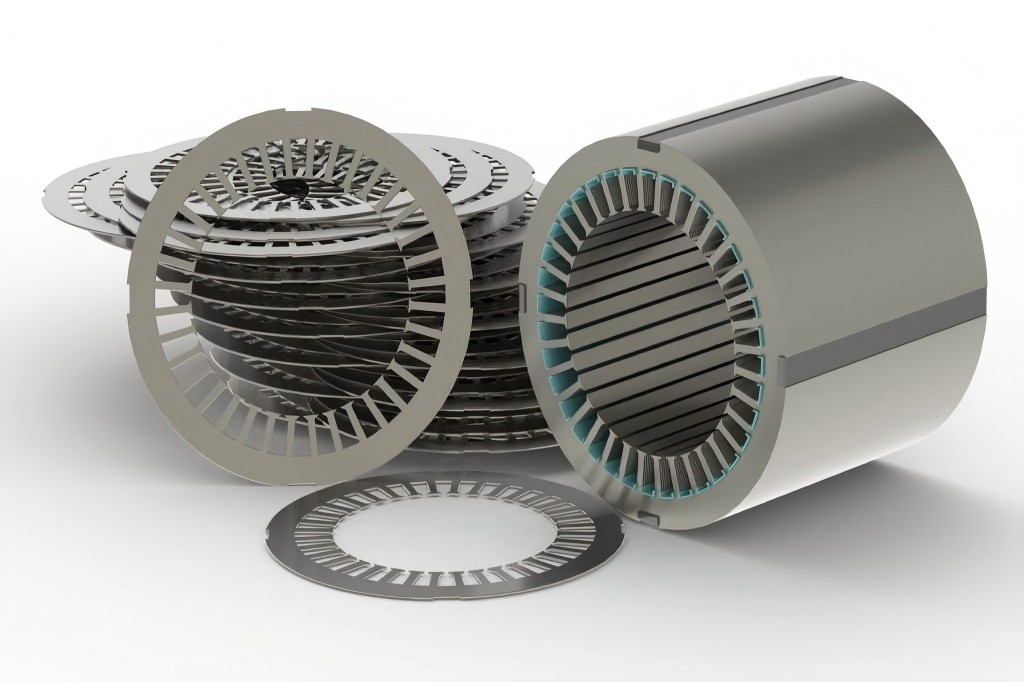

Recent advancements, such as automatic stacking and riveting progressive dies, are revolutionizing stator and rotor core production, offering faster production, reduced errors, and significant cost savings.

Read Article

Electric motors are essential in industries like electronics, automation, and EVs. As demand for efficient, high-performance motors grows, so does the need for quality motor parts.

Read Article

Asynchronous motors, or induction motors, are essential in many industries, powering equipment like pumps, fans, and compressors. However, these motors can experience failures, especially in the rotor and stator.

Read Article

Everything from industrial gear to electric cars and home gadgets is powered by electric motors. At their core are two essential components: the stator and rotor. Each plays a unique role even though they collaborate to transform electrical energy into mechanical power.

Read Article

Motor rotors are essential for converting electrical energy into mechanical power. As demand for higher efficiency and sustainability grows, rotor manufacturers are driving innovation.

Read Article

The shift from traditional to new manufacturing methods for motor stators and rotors is a key milestone in the industry. By using technologies like high-speed stamping, automated winding, and laser cutting, manufacturers cut costs and improve quality, efficiency, and sustainability.

Read Article

The global motor stator and rotor market is growing rapidly, fueled by the rising demand for electric vehicles (EVs), advances in renewable energy, and increasing industrial automation.

Read Article

Motor lamination thickness is crucial for the efficiency and performance of electric motors, especially in applications like electric vehicles, industrial machinery, and power generation.

Read Article

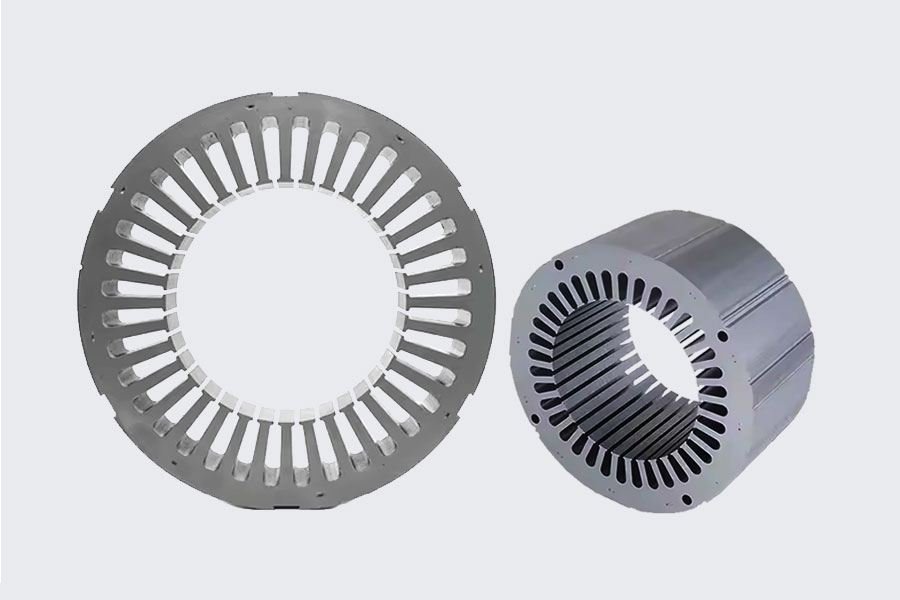

The stator core is crucial for the efficiency, reliability, and performance of electrical motors. Sometimes invisible, it creates the magnetic field that drives the motor.

Read Article