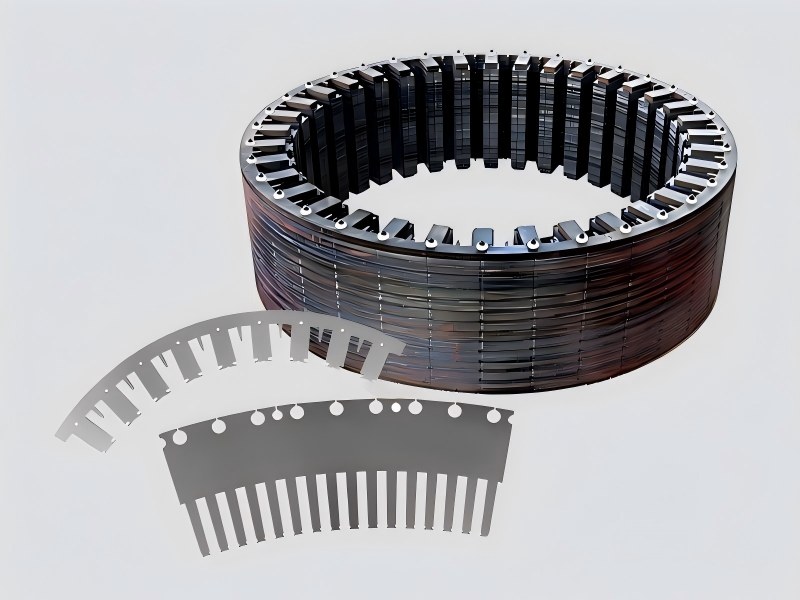

Wind Power Stator

- Size Range: Supports stator diameters from 180 mm to 8000 mm, meeting diverse turbine capacities.

- Superior Reliability: Designed for stable operation under varying temperature, humidity, and load conditions.

- Precision Manufacturing: Multi-row stamping and mold design ensure dimensional accuracy and magnetic consistency.

- Wide Environmental Adaptability: Perfect for plain, high-altitude, low-wind-speed, and offshore applications.

- Low Noise & Vibration: Optimized lamination stacking reduces noise and enhances performance stability.

Technical Specifications

| Parameter | Specification |

| Outer Diameter | 180–8000 mm |

| Material | Silicon Steel Sheet |

| Lamination Thickness | 0.35–0.65 mm |

| Stacking Method | Interlock / Welding / Bonding |

| Application | Wind Energy |

| Certifications | ISO9001, IATF16949 |

Customization & OEM Service

- Drawings: Accept 2D/3D (DXF/DWG/STEP); co-design support available.

- Lamination Thickness: Per spec (e.g., thin gauges for reduced eddy loss).

- Slot/Tooth Geometry: Tailored to copper fill, cooling, and performance targets.

- Stacking Method: Interlock / welding / bonding / riveted per application.

- Insulation Coating: Class and color per standard or customer code.

Application Fields

- Onshore and offshore wind turbines

- High-altitude and coastal installations

- Doubly-fed, direct-drive, and medium-speed generator systems

Production Process

Advanced Workshop