Motor stack length is a key factor that impacts both the performance and efficiency of electric motors. It is essential in determining torque, speed, and energy usage. By understanding stack length, engineers can optimize motor designs to meet specific application needs, improving both efficiency and performance.

This article explores how stack length affects motor performance and how to choose the optimal length for your motor.

What is Motor Stack Length?

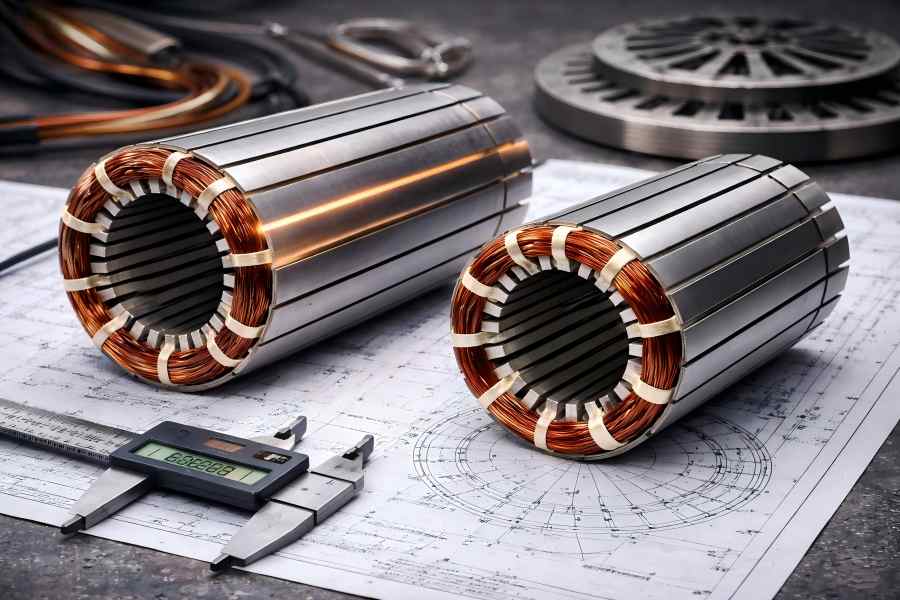

Motor stack length refers to the axial length of the laminated steel core inside the motor. This laminated stack, composed of thin sheets of electrical steel, forms the core structure of both stators and rotors in electric motors. The motor stack length is the measure of how long this stack is, typically extending from the front to the back of the motor assembly.

The purpose of this laminated core is to conduct magnetic flux generated by the motor’s windings. The number of layers, as well as the length of these layers (stack length), directly influences the amount of magnetic flux that can be generated and transmitted through the motor.

Thus, motor stack length is critical to a motor’s performance and efficiency. It determines the motor’s ability to produce torque and power for the desired application while also affecting factors such as energy consumption and heat generation.

How Stack Length Affects Motor Performance

Impact on Torque Output

One of the primary ways stack length influences motor performance is through its effect on torque. The size and strength of the motor’s magnetic field have a significant impact on torque, which is the rotating force produced by the motor.

A longer motor stack provides a greater area for the magnetic field to interact with, resulting in higher torque output.

In motors, increasing the stack length increases the number of magnetic flux lines that can pass through the core, thus generating a higher torque. This is especially crucial for applications like heavy-duty power tools, industrial machinery, and electric cars that need a lot of rotating force.

Influence on Motor Speed and Efficiency

The motor stack length also affects the motor’s speed and efficiency. Longer stack lengths can sometimes lead to a higher operational speed, as they allow more windings to be incorporated into the motor’s design.

However, this comes at a trade-off, as the longer stack can increase the motor’s resistance and reduce its overall efficiency, especially if not properly managed.

For example, in an AC motor, the stack length directly affects the frequency of the alternating current needed to maintain motor rotation.

Longer stack lengths can accommodate higher frequencies and more windings, but this often leads to greater losses due to increased resistance and energy dissipation. Balancing stack length with winding configuration is vital for achieving an optimal speed-to-efficiency ratio.

Relationship with Power Density

Power density refers to the amount of power a motor generates for a given size or weight. Motor stack length influences power density by dictating the available space for the motor’s windings and the amount of magnetic flux the motor can handle.

Shorter stack lengths might lead to more compact, lighter motors with lower torque but better suited for applications where space and weight are critical. On the other hand, longer stack lengths can lead to heavier and bulkier motors, but with higher power outputs.

Therefore, optimizing stack length is key to achieving the best power density for a given application. For instance, in aerospace applications, engineers may favor shorter stack lengths to minimize weight, while industrial applications may prioritize longer stacks for increased torque.

The Effect of Stack Length on Efficiency

Energy Consumption

One of the most significant effects of stack length on efficiency is its impact on energy consumption. The longer the stack, the greater the number of steel sheets in the motor’s core, which can result in increased resistance to the flow of electrical current. This increase in resistance leads to greater energy losses in the form of heat, which directly reduces the motor’s efficiency.

To mitigate this issue, advanced motor designs use better-quality materials, such as silicon steel, that minimize energy loss due to resistance. By adjusting the stack length, engineers can find the balance between efficiency and the required torque output for the motor’s intended use.

Heat Generation and Cooling

Another important consideration is how stack length influences the heat generated by the motor. Longer stack lengths tend to generate more heat, particularly in high-power motors that operate for extended periods. Excessive heat can lead to reduced efficiency, potential damage to motor components, and increased wear and tear on the motor.

Cooling systems such as fans, liquid cooling, and heat sinks are often added to motors with longer stack lengths to ensure that temperatures remain within acceptable limits. Proper heat management is crucial to maintaining the longevity and efficiency of the motor, especially in high-performance applications.

Optimizing Stack Length for Energy Efficiency

When designing a motor for optimal efficiency, engineers must balance the stack length with other design elements, such as the winding configuration, materials, and cooling systems.

In many cases, longer stacks can be beneficial for performance, but the trade-off in energy efficiency and heat generation must be carefully considered.

For energy-efficient applications, a shorter stack length may be preferred, as it can reduce energy consumption and improve overall system efficiency. This is particularly true for applications that don’t require high torque, where a more compact motor can achieve a better performance-to-energy ratio.

Factors Influencing Motor Stack Length

Several factors influence the selection of stack length in motor design. Determining the ideal stack length for a particular motor application requires an understanding of these aspects.

Motor Type (AC vs DC, etc.)

The type of motor—whether AC, DC, or brushless—greatly influences the required stack length. For example, AC motors generally require longer stacks than DC motors to achieve the necessary power density and torque output.

Application and Use Case

Stack length is also heavily influenced by the particular requirements of the application. Motors used in electric vehicles or industrial machinery may benefit from longer stack lengths, as these applications typically require higher torque outputs.

Conversely, motors used in smaller devices such as drones or household appliances may prioritize shorter stack lengths for reduced weight and compact design.

Material Properties of the Stack

The material used for the motor’s laminations also influences the required stack length. High-quality materials with low electrical resistance, such as silicon steel, can reduce the need for excessively long stacks, as they improve energy efficiency and reduce heat generation.

The Trade-offs in Motor Stack Length

Pros and Cons of Increasing or Decreasing Stack Length

There are both advantages and disadvantages to increasing or decreasing the motor stack length:

Advantages of a longer stack length:

- Higher torque output

- Greater magnetic flux capability

- Suitable for high-power applications

Disadvantages of a longer stack length:

- Increased weight and size

- Higher energy losses and reduced efficiency

- Greater heat generation

Advantages of a shorter stack length:

- Lighter and more compact design

- Better energy efficiency for low-power applications

- Lower heat generation

Disadvantages of a shorter stack length:

- Lower torque output

- Limited power generation capabilities

- May require higher motor speeds

Effects on Size, Weight, and Complexity

Increasing the stack length tends to make the motor larger and heavier, which can impact its portability and cost. Conversely, decreasing the stack length can make the motor more compact, but it may sacrifice some torque output and overall performance.

The choice between a longer or shorter stack length depends on the application’s priorities, whether it’s high torque, energy efficiency, or space constraints.

Cost Considerations

Longer stacks typically require more material and more complex manufacturing processes, increasing the cost of the motor. Shortening the stack length can reduce material costs and make the motor more cost-effective, but this may also reduce performance.

How to Choose the Optimal Stack Length

Choosing the optimal stack length for a motor depends on balancing the motor’s performance requirements with energy efficiency, size, and cost constraints. Engineers should consider the following factors:

- Torque requirements: Higher torque demands typically require longer stack lengths.

- Application space: Limited space may necessitate a shorter stack length for compactness.

- Energy efficiency: In low-power applications in particular, shorter stacks are frequently more energy-efficient.

- Material quality: High-quality materials can reduce the need for longer stacks while maintaining efficiency.

Case Studies and Examples

Example 1: Industrial Motor for Heavy-Duty Applications

In industrial applications like manufacturing and heavy machinery, motors with longer stack lengths are often preferred. The higher torque output is essential for lifting heavy loads and driving large equipment. These motors typically have larger cooling systems to control the heat produced by the longer stack.

Example 2: Electric Vehicles

In electric vehicles (EVs), motor stack length is optimized for both torque and energy efficiency. Shorter stacks are typically used in smaller EV motors to reduce weight and improve range. However, longer stacks may be used for higher-end models that require greater torque for acceleration and performance.