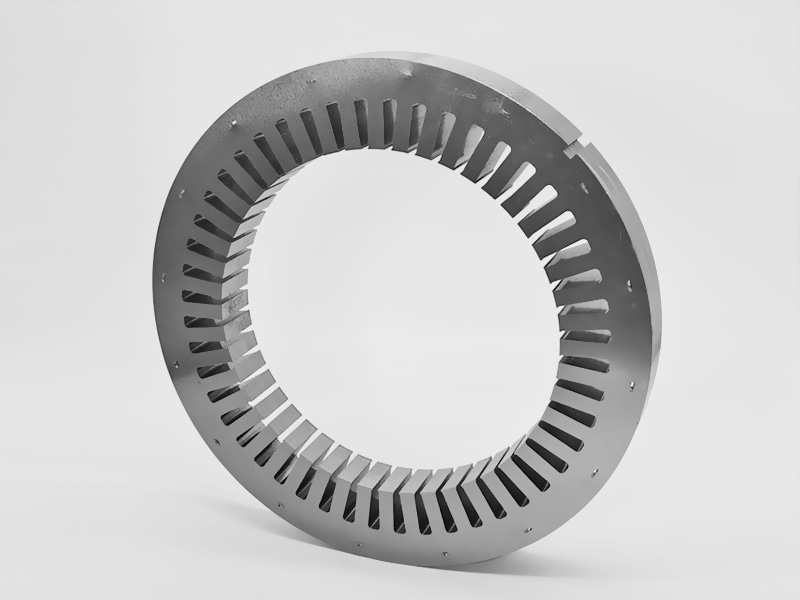

Stator Core for Electric Driven Vehicles-Hybrid Cars

- Small Mass: Lightweight laminated stacks help reduce vehicle mass and improve efficiency.

- High Efficiency: Low hysteresis/eddy losses improve drive range and thermal margins.

- Low Loss: Premium silicon steel and coatings minimize core loss across frequencies.

- Fast Acceleration: Low inertia and optimized slot geometry improve dynamic response.

- High Reliability: Tight tolerances and coating integrity ensure durability under vibration/heat.

Technical Specifications

| Parameter | Specification |

| Material | Silicon Steel Sheet |

| Stator OD Range | 140–240 mm |

| Usage / Motor Type | DC Motor in EV/HEV Drivetrains |

| Structure | Laminated Stack (Precision Punched/Laser Cut) |

| Typical Tolerance | Up to ±0.02 mm (Process-dependent) |

| Lamination Thickness | (0.2–0.5 mm Options—customizable) |

| Insulation | Interlamination Coating Options |

| Brand | OEM & ODM |

| Origin | Jiangsu, China |

| Certifications | ISO9001, IATF16949 |

Customization & OEM Services

- Custom stator diameters, stack height, and lamination thickness.

- Flexible coating and bonding options.

- Prototype-to-mass-production support.

- In-house mold R&D for rapid tooling and precision control.

- Engineering collaboration for hybrid and electric vehicle platforms.

Production Process

Advanced Workshop