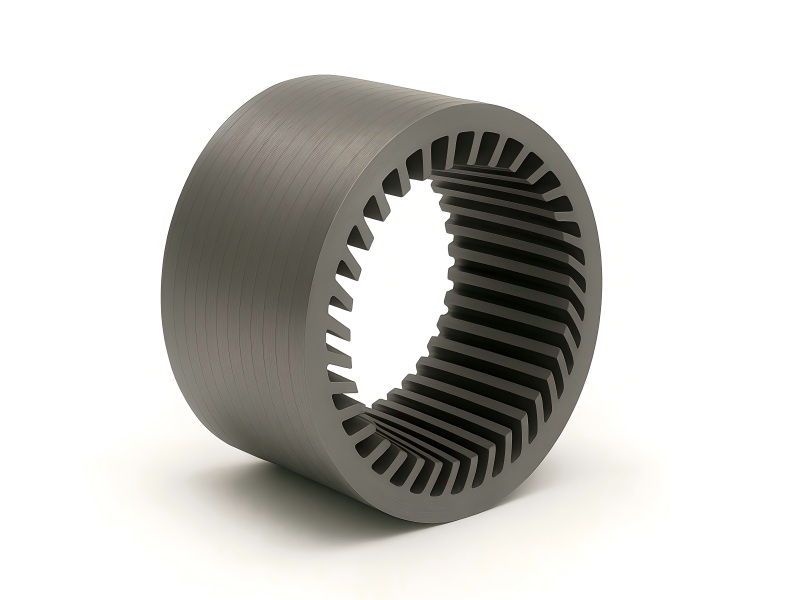

Skewed Stator

- Reduced Cogging Torque: Skew angle of 1–1.5 slot pitch minimizes torque ripple up to 70%.

- High Magnetic Efficiency: Uses non-oriented silicon steel with low core loss ≤ 2.0 W/kg @ 50 Hz.

- Precision Skew Alignment: Automated stacking accuracy within ±0.02 mm ensures consistent offset.

- Customizable Geometry: Supports partial or full-length skew for different rotor topologies.

- Smooth Motor Operation: Delivers stable torque at variable speeds and inverter-driven systems.

Technical Specifications

| Parameter | Specification |

| Material | Non-oriented Silicon Steel / Cobalt Alloy |

| Lamination Thickness | 0.2 – 0.5 mm |

| Outer Diameter | 50 – 600 mm |

| Stack Height | 10 – 500 mm |

| Skew Angle | 0.5–1.5 slot pitch (customizable) |

| Core Loss | ≤ 2.0 W/kg @ 50 Hz |

| Operating Frequency | Up to 400 Hz |

| Tolerance | ±0.02 mm (skew alignment) |

| Applications | Servo Motors / EV Traction / Robotics / HVAC / Appliances |

Customization & OEM Service

- Define skew angle and offset per rotor pole design.

- Select lamination grade and thickness for desired magnetic response.

- Support laser welding, bonding, or riveting stack methods.

- Offer slot geometry and pole-count customization.

- Provide 2D/3D simulation support for torque ripple optimization.

- Deliver samples and full-scale mass production.

- OEM labeling and export packaging available.

Application Fields

- Servo and stepper motors for automation

- Electric vehicle traction and hybrid motors

- Robotics and collaborative arms

- HVAC and air compressor motors

- Low-noise appliances and medical motors

Production Process

Advanced Workshop