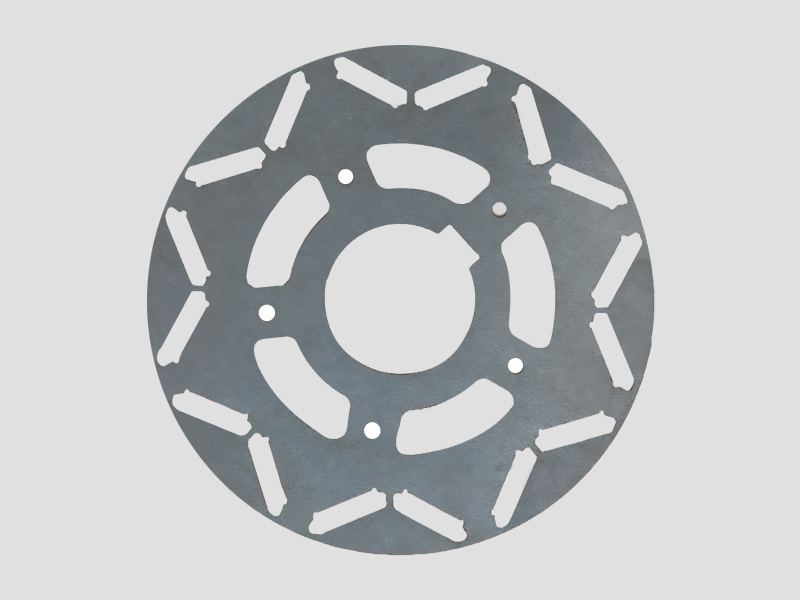

Servo Motor Rotor Stamping

- High-Precision Manufacturing: Achieved using elbow-type punching lines and fine-tuned stamping molds.

- Superior Dimensional Accuracy: Ensures optimal rotor balance and magnetic alignment.

- Enhanced Efficiency: Reduces iron loss, increases torque density, and improves energy conversion.

- Size Range: Covers 10–120 mm, adaptable to various servo motor configurations.

- Stable Performance: Delivers smooth rotation and minimal vibration in high-speed operations.

Technical Specifications

| Parameter | Specification |

| Rotor OD Range | 10 ~ 120 mm |

| Material | Non-oriented Silicon Steel |

| Lamination Thickness | 0.1 – 0.5 mm (Per Design) |

| Stamping Type | Elbow-type Automatic Line |

| Burr Height | ≤ 0.02 mm |

| Stack Assembly | Interlock / Welded / Bonded |

| Certification | ISO9001 & IATF16949 |

| Tolerance Control | Per Drawing / CPK≥1.67 |

Customization & OEM Service

- Material Selection: Recommendation of silicon steel grades for loss and efficiency balance.

- Tooling Development: Custom mold design, tryout, and PPAP submission.

- Stacking Methods: Interlock, bonding, or laser welding options.

- Inspection Reports: Dimensional, burr, and flatness verification upon request.

- Custom Marking: Laser coding and batch identification available.

- Export Packaging: Anti-rust treatment and shock-resistant crates.

Application Fields

- Industrial automation and robotic actuators

- Precision CNC machinery and drives

- Servo motors for motion control systems

- Electronic manufacturing and inspection equipment

- High-speed, high-torque servo applications

Production Process

Advanced Workshop