Servo Motor Rotor

- We design and manufacture servo motor rotors tailored to your application’s dynamics, duty cycle, and environment.

- From prototyping to volume production, our team optimizes geometry, materials, balancing, coatings, and assembly to deliver smooth rotation, high torque density, and long service life.

By Rotor Construction

We manufacture servo motor rotors in multiple construction types, each designed to optimize efficiency, performance, durability, and application-specific reliability.

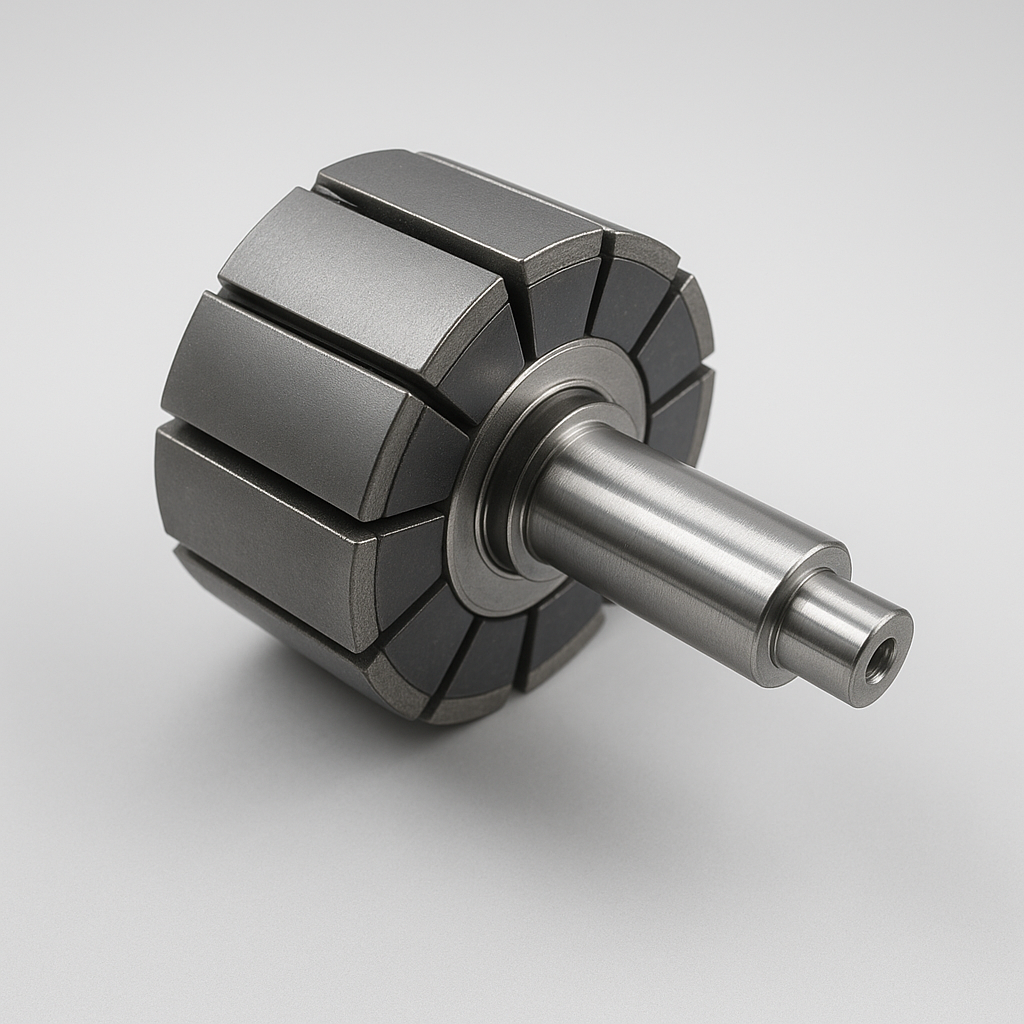

Permanent-magnet Rotors

- High torque density, compact structure, excellent dynamic performance.

- Rare-earth magnets deliver strong flux and stable operation.

- Widely applied in servo drives, robotics, precision positioning.

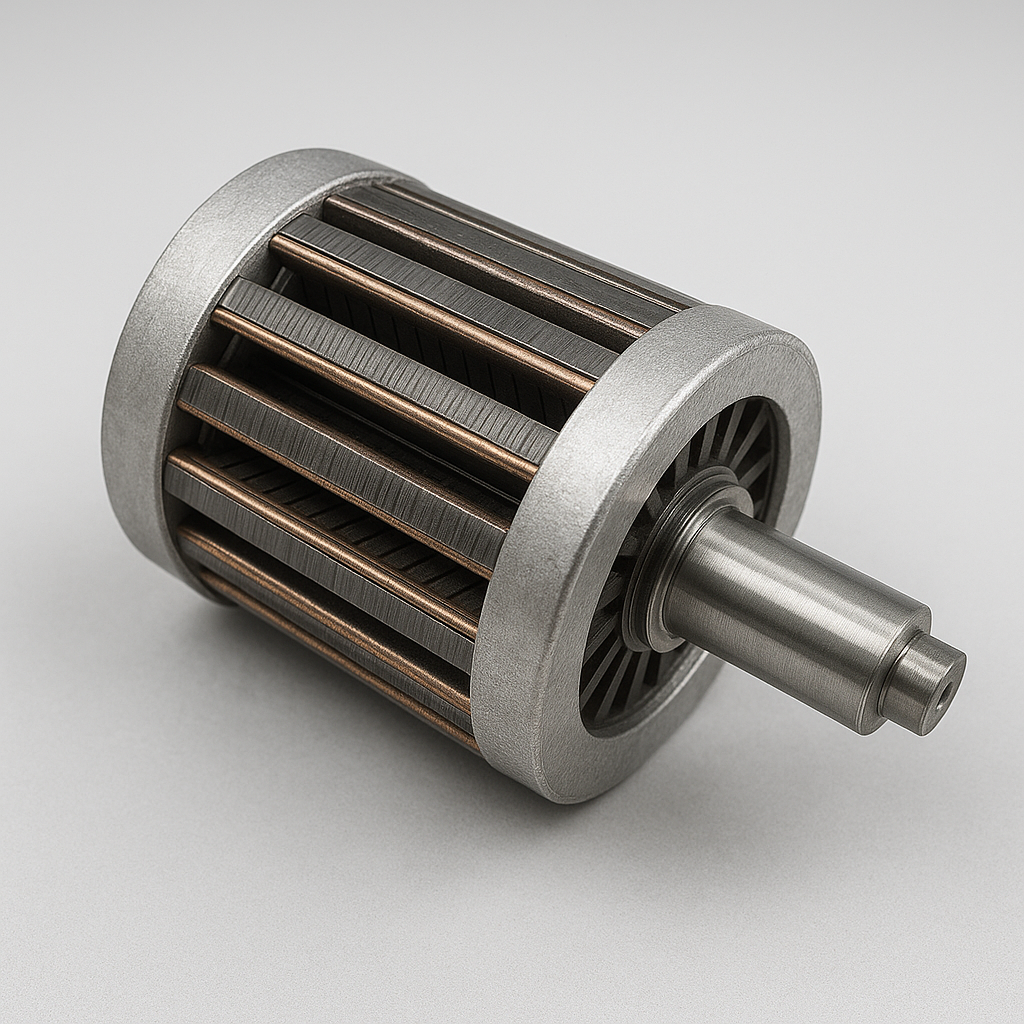

Squirrel-cage Rotors

- Simple construction using aluminum or copper embedded bars.

- Rugged design ensures reliability and minimal maintenance.

- Common in automation systems, pumps, fans, machine tools.

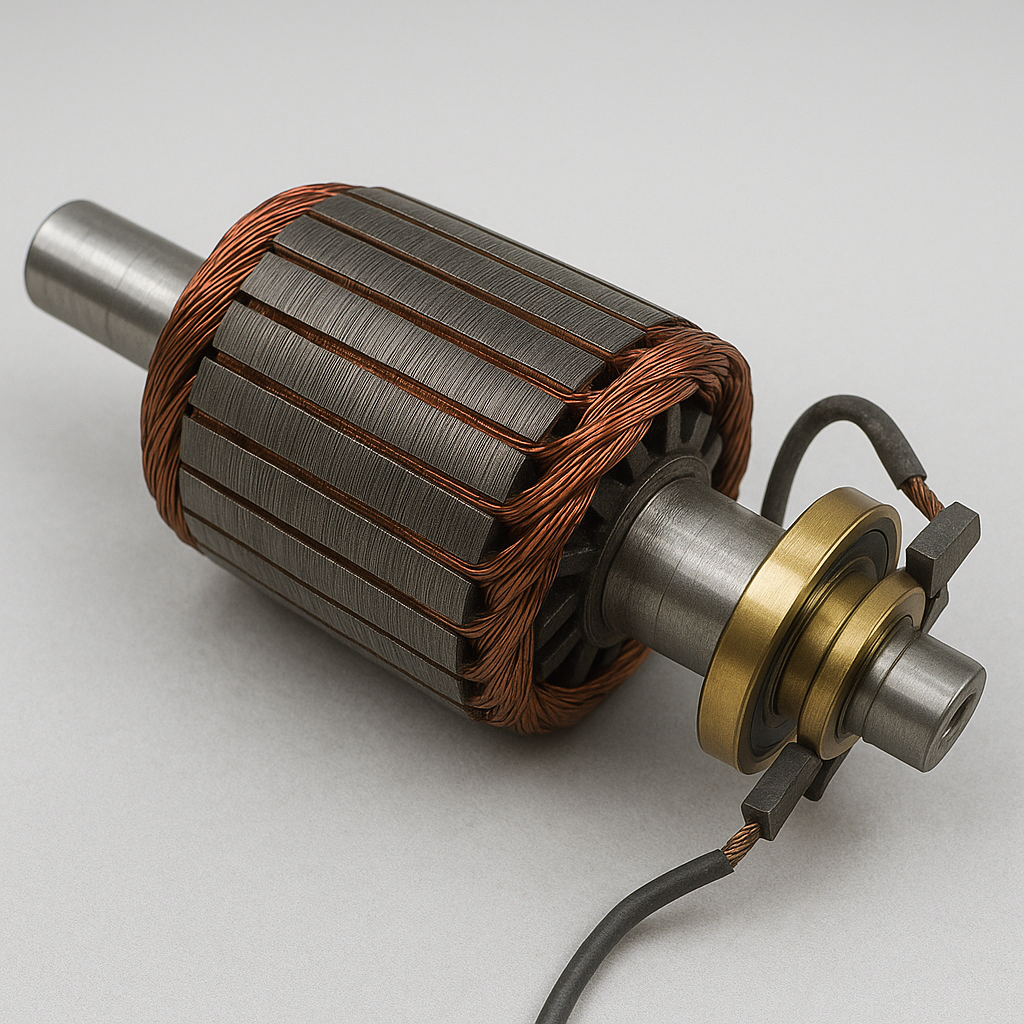

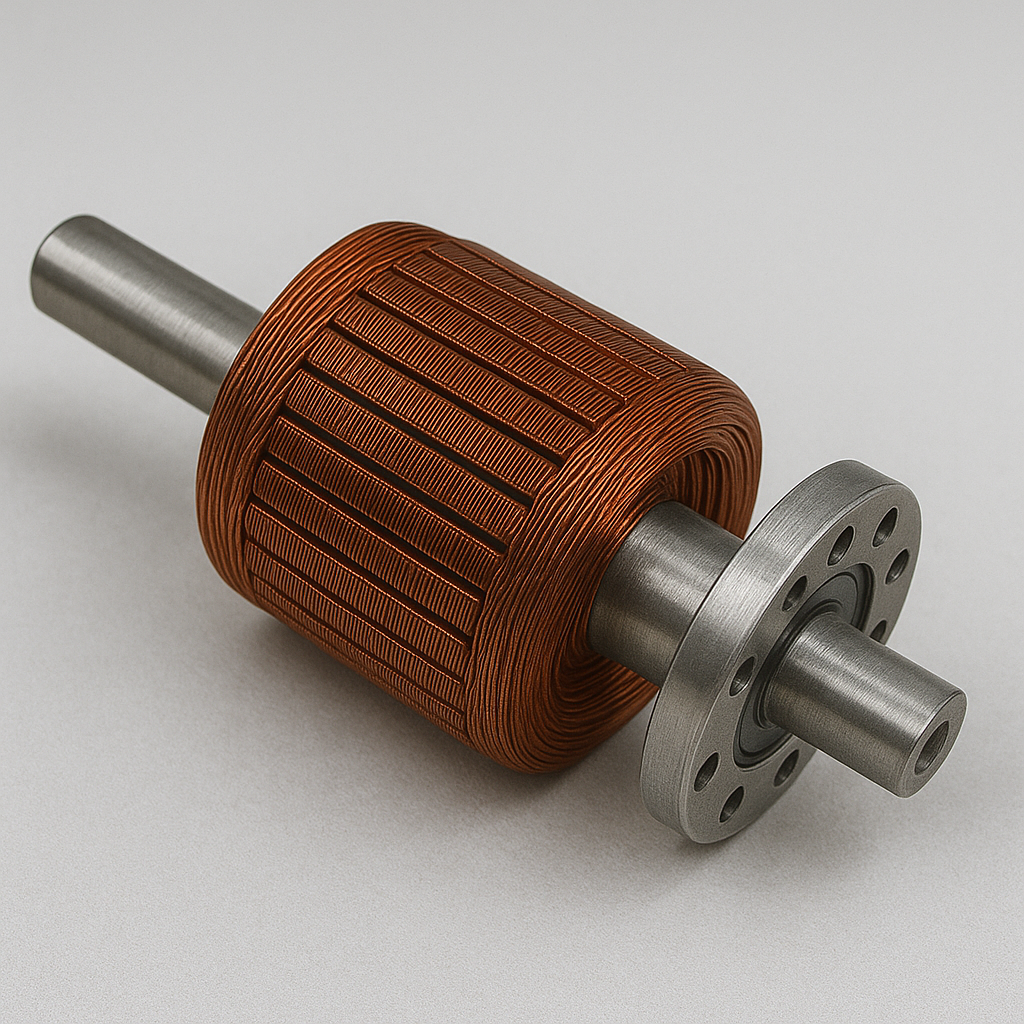

Wound-field Rotors

- Rotor coils generate controllable magnetic field with excitation current.

- Slip rings and brushes provide external power connection.

- Ideal for variable speed drives and large servo systems.

Coreless or Ironless Armature Rotors

- No iron core minimizes cogging torque and reduces inertia.

- Delivers high acceleration, smooth rotation, improved efficiency.

- Preferred in aerospace instruments, medical devices, precision automation.

What We Customize

- We understand every servo application has unique requirements. That’s why we offer fully tailored rotor solutions:

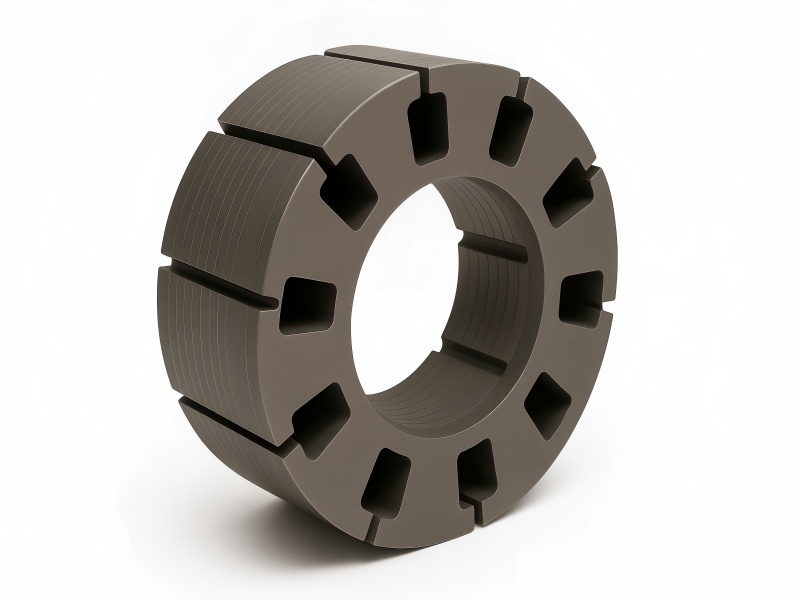

Rotor Core Design

We optimize rotor core geometry and materials to increase torque, efficiency, and minimize losses for precise servo performance.

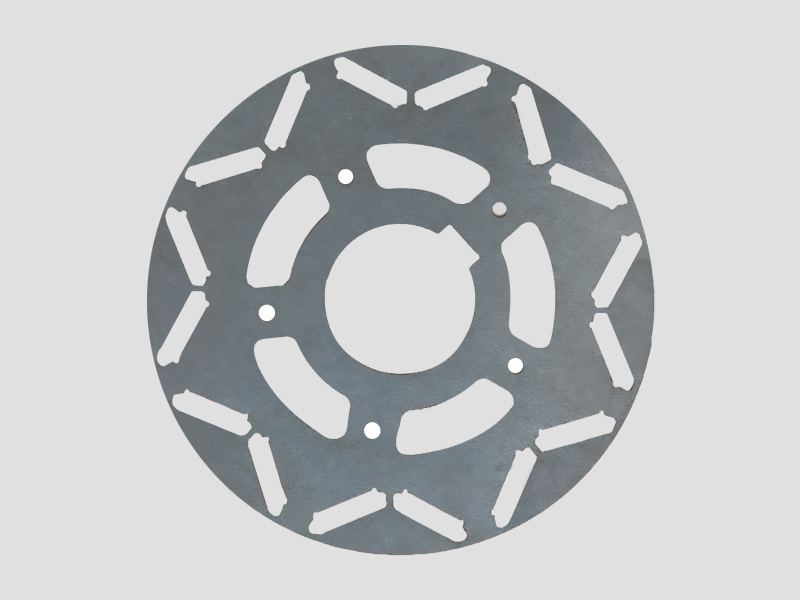

Lamination Stacks

Custom lamination thickness, grade, and insulation reduce eddy currents, control vibration, and improve magnetic uniformity across applications significantly.

Shafts & Hubs

We machine shafts and hubs to exact tolerances for strength, durability, concentricity, and seamless integration with motor assemblies.

Surface Treatment & Coating

We apply tailored surface treatments and coatings to resist wear, reduce friction, prevent fretting, and extend service life.

Anti-rust and Epoxy Coatings

Advanced anti-rust and epoxy systems provide corrosion protection and electrical insulation, improving adhesion, dielectric strength, and durability long-term.

Balancing & Assembly

Precision dynamic balancing and controlled assembly reduce vibration, ensure smooth rotation, and meet stringent servo quality standards consistently.

Typical Capability Ranges

To satisfy a variety of servo motor needs, we offer precise production ranges that guarantee dimensional precision, balance, and dependable high-performance operation.

Parameter | Range / Capability | Notes |

Rotor OD | 20–300 mm | Larger/smaller on request |

Stack height | 10–250 mm | Single or multiple stacks |

Shaft diameter | 3–80 mm | Ground to H7/g6 fit classes |

Lamination thickness | 0.20 / 0.27 / 0.35 mm | Other gauges available |

Concentricity (ID–OD) | ≤0.02–0.05 mm TIR (typical) | Process-capability reports available |

Shaft runout | ≤0.01–0.03 mm TIR (typical) | At bearing journals |

Balance grade | ISO 21940 G2.5 | At use speed, with certificate |

Operating temp | –40 to 180 °C | Depends on magnet/sleeve selection |

Magnet options | NdFeB, SmCo | High-temp H/SH/UH or SmCo for 180 °C+ |

Sleeve burst margin | Engineered per speed | Carbon-fiber or alloy sleeves |

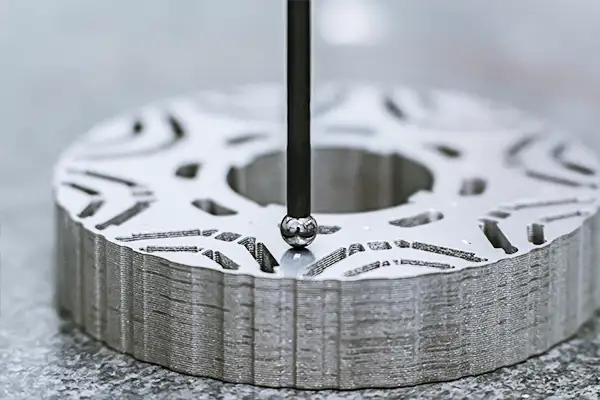

Our Manufacturing Process

- We produce every servo motor rotor with precision machining, advanced balancing, and rigorous inspection to guarantee exceptional performance and reliability.

- Mold Design & Engineering: Develop precision stamping die designs based on prototype data and required servo rotor tolerances.

- Core Lamination Stamping: Punch silicon steel sheets with tight tolerances to ensure magnetic consistency.

- Stacking and Bonding: Assemble laminations under pressure for optimal alignment and mechanical strength.

- Shaft Machining: Turn and grind rotor shafts for precise dimensional accuracy and balance.

- Rotor Assembly: Integrate core, shaft, and key components using high-precision alignment fixtures.

- Dynamic Balancing: Perform multi-plane balancing to minimize vibration and enhance rotational stability.

- Surface Coating: Apply anti-corrosion and insulation coatings for extended durability and performance.

- Performance Testing: Verify torque, inertia, and electrical parameters under controlled test conditions.

- Final Inspection and Packaging: Conduct visual, dimensional, and functional checks before secure packaging.

- We implement rigorous quality testing at every production stage to ensure each servo motor rotor meets strict performance and reliability standards consistently.

- Lamination Inspection: We measure burr height, lamination thickness, and flatness using precision micrometers and optical systems. Interlam insulation and stacking factor are validated for electrical and mechanical consistency.

- Magnet & Sleeve Validation: Magnet grades such as NdFeB and SmCo undergo dimensional, adhesion, and thermal stability checks. Sleeve and adhesive systems are tested under operating speeds to guarantee burst margin and durability.

- Dynamic Balancing & Concentricity: Rotors are balanced to ISO 21940 G2.5 at rated speeds. ID–OD concentricity and shaft runout are verified to tight tolerances using calibrated gauges and runout testers.

- Surface & Coating Durability: We test corrosion resistance and adhesion of coatings, including epoxy, zinc phosphate, and nickel plating, under humidity, salt spray, and vibration exposure to simulate real operating conditions.

- Functional & Acoustic Testing: Torque ripple, vibration, and noise levels are measured across operating speeds. Acoustic noise is validated in controlled test cells to confirm customer specifications and quieter machine performance.

- Traceability & Certification: Every rotor undergoes serialized traceability, with inspection records maintained for lamination quality, balance grade, and coatings. Quality processes comply with ISO 9001, with PPAP or FAIR available upon request.

Featured Products

Servo Motor Core

- Rotor OD: 10–120 mm range

- Lamination Thickness: 0.1–0.5 mm

- Stamping Type: Multi-row or elbow-type

- Stack Assembly: Interlock, bonded, welded

Servo Motor Rotor Stamping

- Material: Non-oriented silicon steel

- Stamping Type: Elbow-type automatic line

- Burr Height: ≤ 0.02 mm

- Tolerance Control: Per drawing, CPK≥1.67

Servo Motor Rotor Core

- Material: Silicon steel or specialty alloys

- Diameter Range: 20–400 mm options

- Stack Height: Fully customizable size

- Rotor Type: Slotted or magnetic insert

Customer Case

- A Tier-1 robotics integrator needed to reduce low-speed torque ripple and vibration without changing the stator or drive.

Our Solution

- Re-designed PM rotor tooth/slot with fractional-slot skew to suppress cogging.

- Upgraded to UH-grade NdFeB; adhesive/sleeve system validated for operating rpm.

- Balanced to G2.5 at 4,500 rpm; tightened ID–OD concentricity ≤0.02 mm TIR.

Results

Metric | Before | After | Delta |

Cogging torque (pk–pk) | 100% baseline | 38% baseline | –62% |

Pick-place repeatability (3σ) | ±0.08 mm | ±0.03 mm | 62% better |

Axis settling time | 210 ms | 140 ms | –33% |

Acoustic noise @1 m | 58 dB | 55 dB | –3 dB |

General FAQs

What materials do you commonly use for Servo Motor Rotor laminations?

We use electrical steel laminations at 0.20, 0.27, or 0.35 millimeters, optimized for low core losses, magnetic uniformity, consistent stamping flatness, and durable interlam insulation.

What surface treatments improve Servo Motor Rotor corrosion resistance?

We offer zinc phosphate, nickel plating, black oxide, and epoxy. Selection depends on environment, insulation needs, and adhesive compatibility for magnets, sleeves, hubs, and interfaces.

What inspection methods verify Servo Motor Rotor lamination quality?

We inspect burr height, interlam insulation, thickness, flatness, and stacking factor using micrometers, optical measurement, Rockwell hardness, and electrical resistivity tests with traceable inspection records.

What is your typical Servo Motor Rotor production lead time?

Lead time depends on lamination tooling, magnet sourcing, and balancing. Prototypes require four to six weeks; repeat orders accelerate once processes, suppliers, and fixtures stabilize.

What certifications support your Servo Motor Rotor quality system?

We operate under ISO 9001 quality management, offer PPAP or FAIR on request, maintain calibrated equipment, documented controls, and serialized rotor traceability across production stages.