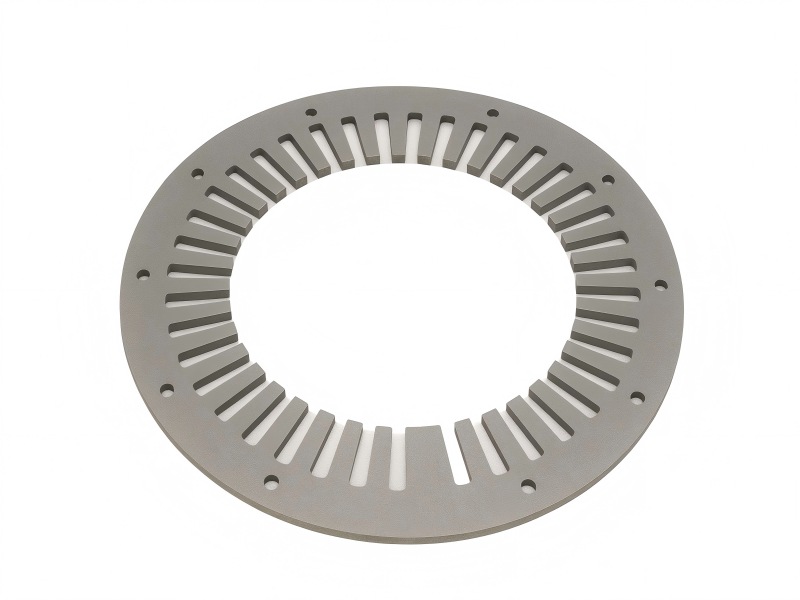

Self-Bonding Stator Laminations

- Precision Thickness Control: Stack height tolerance ≤ ±0.02 mm for dimensional stability.

- High Bonding Strength: Heat-activated resin ensures secure adhesion between laminations under 150–200 °C curing.

- Improved Magnetic Efficiency: Maintains uniform flux path with no weld-induced stress points.

- Clean Appearance: No burrs, rivets, or weld marks for improved aesthetics and balance.

- Lightweight Design: No added fasteners or weld beads, reducing total motor mass.

Technical Specifications

| Parameter | Specification |

| Material | Non-Oriented Silicon Steel / Amorphous Alloy (optional) |

| Lamination Thickness | 0.1 – 0.5 mm |

| Insulation Type | Heat-Activated Epoxy/Polyester Bonding Coating |

| Bonding Temperature | 150–200 °C |

| Stack Height Tolerance | ≤ ±0.02 mm |

| Burr Height | ≤ 0.02 mm |

| Magnetic Flux Density | 1.0 – 1.8 T |

| Insulation Class | F/H |

| Applications | EV Motors / Servo Motors / Aerospace / Medical Equipment |

Customization & OEM Service

- Choose silicon steel or amorphous alloy base material.

- Define lamination thickness and outer/inner diameter.

- Adjust insulation class (F/H) and resin bonding type.

- Specify bonding strength and curing parameters.

- Design stack geometry for stator or rotor configurations.

- Include prototype testing and PPAP documentation.

- Offer OEM labeling and export packaging.

Application Fields

- EV and hybrid traction motors

- Servo and stepper motors

- High-precision aerospace actuators

- Medical and laboratory drives

- Industrial automation systems

Production Process

Advanced Workshop