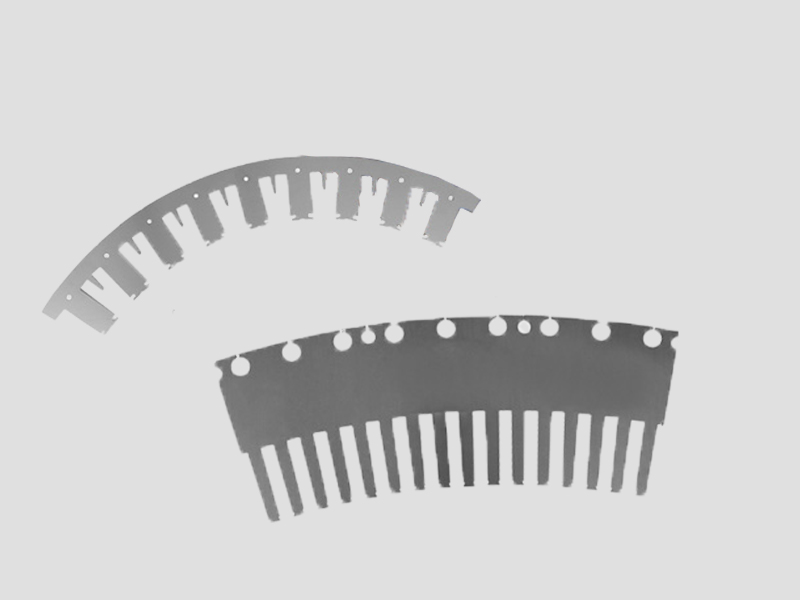

Segmented Stator Laminations for Wind Energy

- High Efficiency: Low-loss silicon steel ensures optimal energy conversion and generator output.

- Excellent Reliability: Rigid lamination structure withstands high torque and vibration loads.

- Versatile Compatibility: Supports DFIG, medium-speed, and direct-drive generator designs.

- Environmental Adaptability: Performs reliably across plain, low-wind, high-altitude, and offshore environments.

- Size Range: Stator segment diameters are available from 180 mm to 8000 mm, customizable for various generator platforms.

Technical Specifications

| Parameter | Specification |

| Place of Origin | Jiangsu, China |

| Brand Name | OEM & ODM |

| Material | Silicon Steel Sheet |

| Size Range (Stator) | 180–8000 mm |

| Burr Height | ≤ 0.02–0.05 mm (grade-dependent) |

| Segment Angle Deviation | ≤ ±0.05° (tooling-dependent) |

| Slot Pitch Error | ≤ ±0.03–0.05 mm |

| Roundness (Assembled) | Project-specific per diameter |

| Certification | ISO9001, IATF16949 |

| Application | Wind Energy (onshore/offshore, low-wind, high-altitude) |

Customization & OEM Service

- Stator Size Customization: Range from 180–8000 mm, adaptable for various wind turbine designs.

- Material Options: Multiple silicon steel grades available for efficiency optimization.

- Segment Design: Tailored segment geometry for assembly precision and performance stability.

- Punching Process: Support for compound, high-speed, and segmental punching technologies.

- Prototype & Mass Production: Fast development cycle from sample to large-scale manufacturing.

- Engineering Collaboration: Assistance with generator design, magnetic optimization, and structural simulation.

Application Fields

- Plain wind power generators

- High-altitude and low wind speed wind turbines

- Offshore wind power systems

- Doubly-fed asynchronous generators

- Medium-speed and direct-drive generators

Production Process

Advanced Workshop