Progressive high-speed stamping is a critical manufacturing process for motor laminations, impacting part quality, throughput, and overall production cost.

As electric motors become more efficient and complex, understanding cost dynamics behind progressive high-speed stamping helps buyers make smarter sourcing decisions.

What Is Progressive High-Speed Stamping?

Progressive high-speed stamping is a metal forming process where electrical steel strips are fed through a series of die stations. At each station, punches, dies, and forming tools progressively shape, cut, and form laminations for motors.

Unlike simple blanking or single-station stamping, progressive dies perform multiple operations in one linear tool, reducing handling and enabling high unit throughput—often thousands of parts per hour.

Key characteristics include:

- Multi-station die sets

- Continuous strip feeding

- Automated material indexing

- High production speeds (500–2,000 strokes/min or more)

- Tight dimensional control

For motor laminations, this process delivers consistent form, minimal scrap, and repeatable geometry essential for low core loss and efficient magnetic performance.

Why Understanding Stamping Cost Matters

For OEMs and motor manufacturers, stamping cost represents a broader cost factor that impacts:

- Part affordability and profit margins

- Tooling amortization over production volume

- Supplier selection and capacity planning

- Total cost of goods sold (COGS)

- Production scalability and lead time

Without clear cost insights, buyers risk paying too much, choosing unsuitable suppliers, or facing surprises such as tooling changeover charges and unaccounted quality costs.

Cost Components of Progressive High-Speed Stamping

Progressive high-speed stamping cost for motor laminations is comprised of several discrete components that together determine the unit price. These include:

- Tooling Cost

- Material Cost

- Pressing/Production Cost

- Setup and Changeover Cost

- Quality Assurance Cost

- Overhead and Profit Margin

1. Tooling Cost

Tooling cost represents one of the largest upfront investments in progressive stamping. It includes die design, die fabrication, tool steel, electrodes, fixtures, guides, tooling frames, and hardening processes.

Tooling cost depends on:

- Number of stations in the progressive die

- Complexity of lamination profile

- Precision and tolerance requirements

- Material thickness and coating type

- Wear-resistant materials (e.g., nitrided, PVD/DLC coating)

- Complexity of pilots and strip guides

For motor laminations with multiple slots, inner radii, and interlocks, progressive dies can be complex and expensive.

Typical tooling cost categories:

| Tooling Component | Description |

| Die block & inserts | Core metalwork that defines part geometry |

| Punches | Cutting and forming elements |

| Strippers & pilots | Feed control and material stripping |

| Guides & bearings | Precision indexing and alignment |

| Hardening/coating | For wear resistance at high speed |

Depending on part complexity, tooling costs may be as low as several thousand dollars or rise to tens of thousands for intricate motor laminations.

Because tooling cost is amortized over production volume, higher volumes lower the per-part contribution of tooling cost.

2. Material Cost

Material cost covers the raw electrical steel strip used to produce the laminations.

Factors affecting material cost:

- Steel grade (e.g., M19, M27, high-silicon alloys)

- Thickness (0.20 mm, 0.35 mm, etc.)

- Width of strip (affects nesting efficiency)

- Coated vs. uncoated (some magnet steels have insulating coatings)

- Supplier pricing and market fluctuations

Because motor laminations are typically stamped from high-grade electrical steel, material cost can be 30–50% of the total part cost, especially when rare grades or tight thickness tolerances are required.

3. Pressing/Production Cost

Pressing cost includes machine time, labor, utilities, and maintenance during normal production.

Production cost depends on:

- Press type and capacity (servo vs. mechanical, tonnage)

- Production speed (strokes per minute)

- Crew size & skill level

- Energy cost

- Downtime and changeover time

High-speed presses operate faster but may require more frequent maintenance, higher energy draw, and more skilled operators. Balancing speed and cost is key.

Production cost may be calculated using:

Pressing Cost = (Hourly Machine Cost × Run Time) + Labor Cost

Example:

If a press runs $60/hour and parts run for 10 hours at 1,000 pcs/hour:

- Pressing cost = $60 × 10 = $600

- Per-part cost = $600 / 10,000 = $0.06 per part

Add labor: if an operator works at $20/hour (for 10 hours = $200), then labor per part = $0.02.

Total pressing cost per part = $0.08

(These are illustrative numbers; actuals vary by region and volume.)

4. Setup and Changeover Cost

Setup includes:

- Die installation and calibration

- Press adjustment

- Strip feeding alignment

- First article inspection

Changeover cost arises when tooling is removed for another job.

Setup cost is often fixed per run, so it is most impactful for low volumes.

Example:

If setup takes 4 hours at $80/hour press rate + labor:

- Setup cost = $320

- If only 1,000 parts are made, per part = $0.32

- If 20,000 parts are made, per part = $0.016

Thus, volume dramatically affects setup cost contribution.

5. Quality Assurance Cost

Quality cost includes:

- In-line inspection (optical, laser, vision systems)

- Sampling and testing (dimensional, magnetic properties)

- Secondary inspection for burrs, cracks, warping

- Scrap and rework associated with defects

Higher precision or tighter tolerances generally require more inspection effort, raising cost.

For motor laminations, suppliers often include:

- Visual inspections

- Dimensional gauging

- Core loss and permeability testing on sample

Quality cost may be managed through:

- SPC (Statistical Process Control)

- Automated inspection to reduce manual labor cost

- Preventive maintenance to reduce defect rates

6. Overhead and Profit Margin

This covers:

- Factory overhead (utilities, rent, supervision)

- Tool storage and maintenance

- Administrative costs

- Supplier profit margin

Overhead is typically absorbed into per-part cost by allocating total overhead over production volume.

Profit margin varies by supplier and market; typically 10–30% on stamping operations.

How Progressive Stamping Cost is Calculated

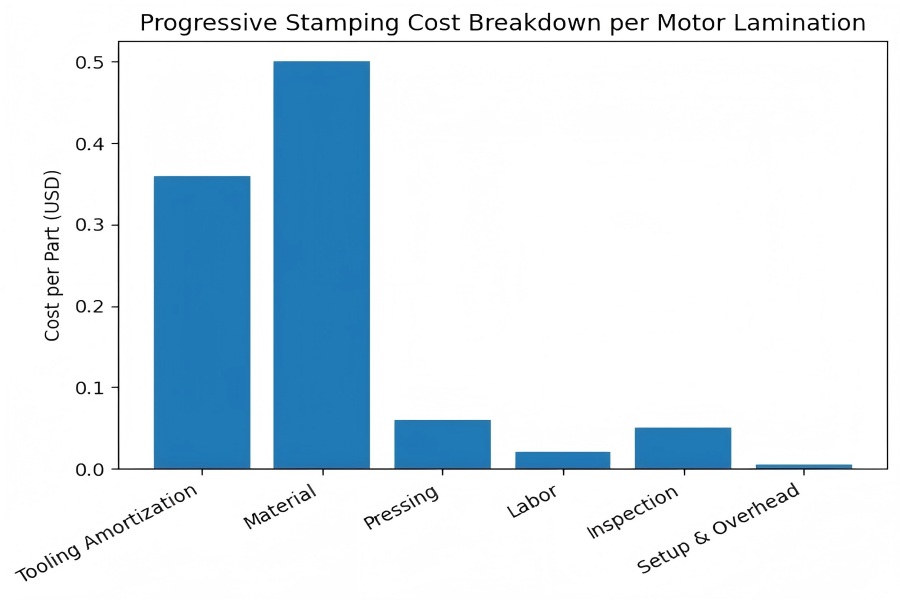

Let’s illustrate a simple cost calculation for a motor lamination job.

Example Job

- Volume: 50,000 laminations

- Pressing rate: 1,000 pcs/hour

- Pressing cost: $60/hour

- Labor cost: $20/hour

- Die cost: $18,000

- Material cost per strip: $0.50/lamination

- Inspection cost: $0.05/lamination

Step-by-Step Breakdown

- Tooling amortization

Tooling cost ÷ volume = $18,000 / 50,000 = $0.36 per part

- Material cost

Direct material = $0.50 per part

- Pressing cost

Pressing cost/hour = $60

Production hours = 50 hours

Pressing cost = $60 × 50 = $3,000

Pressing cost per part = $3,000 / 50,000 = $0.06

- Labor cost

Labor cost/hour = $20

Labor = $20 × 50 = $1,000

Labor per part = $1,000 / 50,000 = $0.02

- Inspection cost

Inspection = $0.05 per part

- Setup cost

Assume 2 hours at $80/hour total = $160

Per part = $0.0032 (negligible with large volume)

Total per part cost

| Cost Component | Unit Cost |

| Tooling amortization | $0.36 |

| Material | $0.50 |

| Pressing | $0.06 |

| Labor | $0.02 |

| Inspection | $0.05 |

| Setup & overhead | ~0.005 |

| Total Estimated Cost | $1.01 |

In this example, the stamping cost for a lamination is approximately $1.01.

Actual costs vary significantly by region, steel grade, tolerances, and supplier efficiency.

Factors That Affect Progressive Stamping Cost

Buyers are better able to negotiate and estimate budgets when they are aware of the factors that affect costs.

Material Grade and Thickness

High-silicon or specialty electrical steels cost more than low-grade steels and may require slower feeds or special tooling coatings.

Thinner material increases scrap control requirements and may reduce tool life.

Part Complexity

Features such as:

- multiple slots

- narrow teeth

- inner cutouts

- interlocking tabs

Tolerance and Precision

Tighter tolerances require:

- premium tooling

- more frequent inspection

- slower production for reduced variation

Batch Size and Order Frequency

Small batches have higher per-unit setup cost. Frequent changeovers raise average cost per part.

Press Capability

High-speed presses deliver more units per hour but may incur:

- Higher tooling wear

- Higher maintenance cost

- Specialized training

Supplier Geography

Labor, utilities, and overhead differ by region. Suppliers in low-cost regions may offer lower per-unit pricing—but buyers should also evaluate quality systems, delivery reliability, and logistics cost.

Cost Comparison: Progressive vs Conventional Stamping

Stamping methods differ significantly in cost structure, speed, and scalability, making process selection critical for motor lamination production efficiency.

| Aspect | Single Slot Stamping | Compound Stamping | Progressive High-Speed Stamping |

| Setup Cost | Very low | Medium | High |

| Tooling Cost | Low | Medium–High | High |

| Per-Part Cost at Low Volume | Competitive | Moderate | Least competitive |

| Per-Part Cost at High Volume | High | Moderate | Very competitive |

| Production Speed | Low | Medium | Very high |

| Part Complexity Handling | Limited | Good | Excellent |

| Dimensional Consistency | Moderate | Good | Excellent |

| Scrap Control | Low–Moderate | Moderate | High |

| Automation Level | Low | Medium | High |

| Best Application Range | Prototypes, small batches | Medium volumes | High volumes, complex geometries |