In today’s fast-moving world of high-speed electric motors—used in EVs, drones, robotics, and aerospace—demands for higher efficiency, lighter weight, and more power are growing. A key innovation meeting these needs is optimized rotor-stator bonding. This method improves both strength and heat handling in motors running at high speeds.

This article explains how the bonding works, what materials it uses, and why it’s becoming a new standard in advanced motor design.

The Rising Demand for High-Speed Motors

Electrification is accelerating in almost every industrial sector. The transition from mechanical to electromechanical systems has placed electric motors at the center of innovation, particularly in applications requiring high rotational speeds.

Whether in EV traction motors spinning beyond 20,000 RPM or drones demanding ultra-lightweight propulsion systems, the performance of a motor hinges on more than just electromagnetic design—it also depends on how well the rotor and stator are assembled and bonded. Poor bonding can lead to mechanical imbalance, vibrations, and even catastrophic failure under centrifugal forces.

Why Rotor-Stator Bonding Matters More Than Ever:

- Minimizes relative motion and eccentricity under load

- Reduces vibrations and acoustic noise

- Enhances thermal conduction from winding to housing

- Eliminates need for excessive mechanical fasteners or interference fits

- Prevents delamination or rotor-stator misalignment

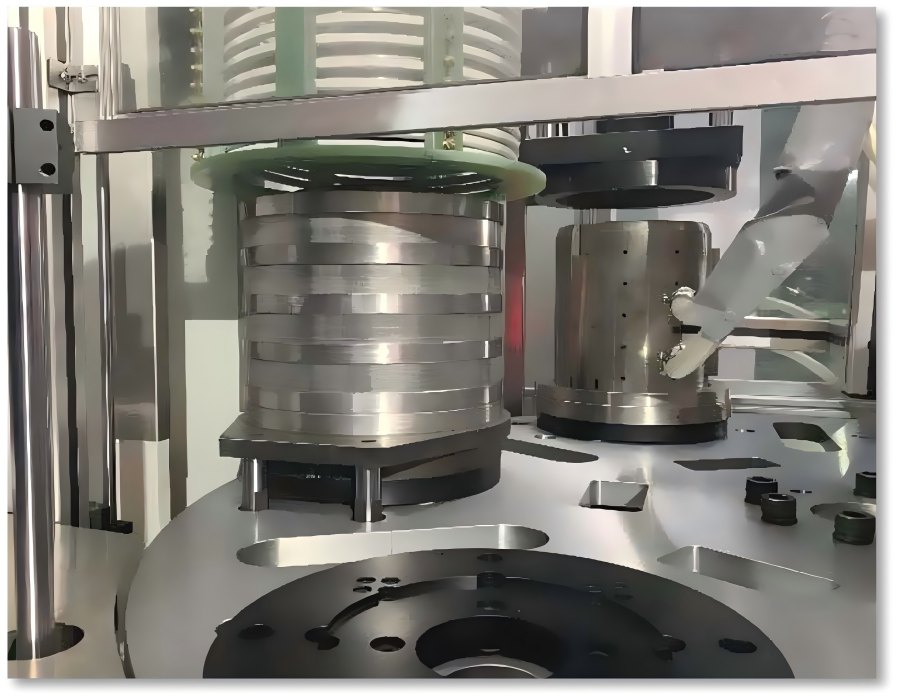

Rotor and Stator: A Brief Engineering Overview

To appreciate the importance of bonding, we need to revisit the fundamental components of electric motors.

Stator

The stator is the fixed portion of the motor, housing windings or coils that create a revolving magnetic field when powered. To reduce eddy current losses, electrical steel sheets are usually laminated. The stator must remain rigid and precisely aligned to generate consistent torque and avoid magnetic losses.

Rotor

The rotor, positioned inside the stator, turns when acted upon by the magnetic field produced by the stator. Rotors can be of various types—squirrel cage, permanent magnet (PM), or wound. At high speeds, rotors endure tremendous centrifugal forces that can deform the structure if bonding is inadequate.

The Air Gap

The microscopic clearance between the rotor and stator, known as the air gap, is typically just 0.2 mm to 1.5 mm. Any axial or radial misalignment—often caused by poor bonding—can result in performance losses and excessive wear.

Traditional Assembly Methods and Their Limitations

Historically, rotors and stators have been connected and aligned using a combination of mechanical fasteners, press fits, keyways, shrink fits, and interlocking laminations. While effective at moderate speeds, these methods face limitations in high-speed applications:

| Method | Limitations |

| Shrink Fit | Thermal cycling can loosen the fit; stress concentrations can cause cracking |

| Press Fit | Difficult to maintain concentricity; potential for distortion during assembly |

| Keyed Shafts | Introduces stress risers and potential points of failure |

| Bolted Assembly | Adds mass and complexity; weakens structural integrity under dynamic load |

In high-speed environments, these limitations lead to noise, vibration, heating, and early motor failure.

Enter Optimized Rotor-Stator Bonding

What is Optimized Bonding?

Optimized rotor-stator bonding refers to the use of high-performance adhesives, thermal interface materials, and precision alignment processes to securely join rotor and stator components without the drawbacks of traditional mechanical methods.

This bonding technique focuses on achieving:

- Uniform distribution of load and stress

- Enhanced thermal conductivity

- Reduced mechanical tolerances

- Durability under extreme operating conditions

Materials Used in Bonding

Advanced bonding solutions use materials specifically designed to meet the peculiar requirements of electric motors.

Adhesives

- Epoxy-based adhesives: Offer strong bonding strength and good thermal resistance

- Acrylic adhesives: Provide faster cure times and flexibility under vibration

- Silicone adhesives: Used where elasticity and temperature fluctuations are significant

Thermal Interface Materials (TIMs)

- Used to improve heat conduction between bonded surfaces

- Reduces thermal resistance, improving motor efficiency

- Prevents hot spots on stator windings

Filler and Reinforcement Materials

- Ceramic fillers improve thermal conductivity

- Carbon-based nanomaterials can enhance both electrical insulation and heat dissipation

The Process: How Optimized Bonding is Performed

Surface Preparation

- Cleaning with solvents to remove oil and contaminants

- Surface roughening to enhance adhesive grip

- Application of primers if necessary

Application of Adhesive or TIM

- Dispensed in automated or semi-automated systems

- Ensures even layer thickness (typically 50 to 200 microns)

- Avoids air entrapment and voids

Curing Process

- Heat curing in ovens (80°C–150°C depending on adhesive type)

- UV curing in fast-cure environments (for some light-sensitive adhesives)

- Time-controlled setups to maintain alignment during cure

Quality Control

- Bond line inspection (using ultrasonic or thermographic imaging)

- Destructive shear tests for sample pieces

- Vibration and thermal cycling tests

Benefits of Optimized Bonding in High-Speed Motors

| Advantage | Effect on the Performance of the Motors |

| Improved Concentricity | Minimizes torque ripple and magnetic noise |

| Enhanced Thermal Path | Improves power density and insulation life |

| Lower Mass | Removes bulky fixtures, improving power-to-weight ratio |

| Better NVH Characteristics | Lowers noise, vibration, and harshness |

| Long-Term Durability | Withstands temperature, centrifugal force, and shock loading |

For motors operating at 20,000–100,000 RPM, optimized bonding is not just beneficial—it’s essential.

Use Cases: Where Optimized Bonding Makes the Difference

Electric Vehicles (EVs)

- Application: Traction motors, e-axles, and in-wheel motors

- Benefit: Lower NVH and improved efficiency at high torque demand

Aerospace

- Application: Propulsion systems, fuel pumps, cabin pressurization

- Benefit: Extreme weight reduction and vibration resistance

Robotics

- Application: Actuators, servo motors, precision motor systems

- Benefit: Higher precision, tighter control loops, reduced backlash

Medical Devices

- Application: High-speed centrifuges, surgical tools

- Benefit: Compact, low-noise, and vibration-free operation

Drones and UAVs

- Application: Brushless outrunner motors

- Benefit: Reduced mass, better energy efficiency, quieter operation

Challenges and Considerations in Rotor-Stator Bonding

Despite its many advantages, optimized bonding requires stringent process control and advanced material science.

Thermal Mismatch

Differential expansion between bonded components can cause long-term delamination if adhesive elasticity is not tuned correctly.

Curing Time vs. Production Speed

Faster adhesives often trade-off with bonding strength. UV-cured solutions are promising but may require transparent or translucent bonding zones.

Aging and Fatigue

Long-term fatigue resistance must be validated under accelerated lifecycle tests. Moisture ingress, outgassing, and material creep are typical aging factors.

Cost

Advanced bonding materials are more expensive than mechanical joining elements. However, they are offset by performance and lifespan gains.

Simulation and Digital Twin Approaches

Modern design approaches are leveraging multiphysics simulations to model the rotor-stator bonding process.

- Thermal models: Predict temperature gradients and adhesive aging

- Mechanical models: Simulate stress propagation and delamination risks

- Vibration analysis: Ensure resonance avoidance and mechanical damping

- CFD simulations: Predict airflow around the motor for better cooling design

Digital twins allow continuous monitoring of adhesive bond health through embedded sensors, enabling predictive maintenance.

Standardization and Regulatory Trends

ISO and IEC Standards

While current standards mostly address motor performance, growing adoption of bonding in safety-critical systems like EVs and aircraft motors is prompting the need for:

- Standard test protocols for adhesive performance

- Thermal conductivity benchmarking

- Fatigue life testing frameworks

Manufacturers are increasingly aligning with IATF 16949, ISO 26262, and IEC 60034 in their design and quality control processes for bonded assemblies.

Future Outlook: What’s Next in Rotor-Stator Bonding

Smart Adhesives

- Incorporate self-healing polymers or embedded sensing particles

- Enable real-time condition monitoring of bond integrity

AI-Driven Process Optimization

- Machine learning models predict ideal curing conditions and adhesive volumes

- Closed-loop quality control using vision systems and robotics

Integration with Additive Manufacturing

- 3D-printed motor components with integrated adhesive channels

- Hybrid bonding + printing for custom lightweight geometries

Recycling and Sustainability

- Development of reversible adhesives for easy motor disassembly

- Eco-friendly formulations to replace petroleum-derived adhesives

Conclusion

Optimized rotor-stator bonding is changing the electric motor industry. Instead of using heavy mechanical parts, designers now use smart adhesives and thermal materials to boost performance, strength, and size efficiency.

As high-speed motors power more technologies—from drones to electric aircraft—this bonding method is key to pushing limits in modern motors.