Motor Stator and Rotor Manufacturer

- We engineer stators and rotors from low-loss electrical steel with precision slotting and tight air-gap control for higher efficiency and low noise.

- From lamination stacking and skewing to G2.5 balancing and Class F insulation, we customize to your voltage, poles, and duty.

- Build-to-Print or Design-to-Spec

- Supports Broad Motor Architectures

- ISO 9001 & IATF 16949 Systems

- RoHS/REACH-Compliant Materials & Finishes

- Flexible Supply: Stator, Rotor, or Matched Assembly

How the Motor Stator and Rotor Work Together?

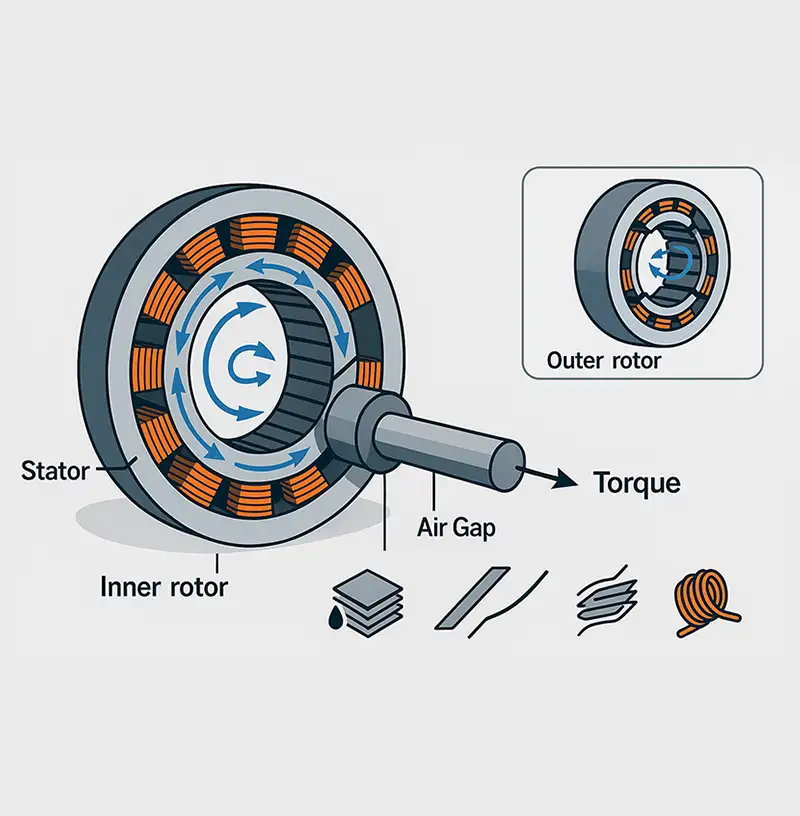

- Stator (Stationary): Laminated steel core with insulated copper windings creates a rotating magnetic field when energized.

- Rotor (Rotating): Sits inside (inner-rotor) or around (outer-rotor) the stator. The coupling of rotor and stator magnetic fields creates torque at the shaft.

- Air Gap: The small clearance between stator and rotor. Minimizing variation here is critical for efficiency, noise, and torque ripple.

- Loss Management: Electrical steel grade, lamination thickness, skew strategy, slot/pole combination, and winding scheme all determine core loss, copper loss, and overall efficiency.

- Result: The stator defines the field; the rotor converts it into motion. Precise geometry, materials, and assembly quality make the difference between a motor that merely turns and a motor that wins on performance, heat&life.

Our Product Range

We offer build-to-print and design-to-spec manufacturing. Choose individual components or matched sets.

Motor Stators

- Precision laminated cores and insulated windings for efficiency, low losses, tight air-gap control, and scalable sizes, materials, and slot counts.

Motor Rotors

- Die-cast or laminated designs with balanced hubs, optimized magnetic circuits, premium magnets or cages, ensuring torque density, stability&durability.

Combination Purchases

- Matched stator-rotor pairs optimized together reduce air-gap variation, streamline sourcing, accelerate validation, and save 10-15% overall on procurement.

Supported Motor Types

We manufacture stator and rotor cores for a broad range of electric motor architectures and frame sizes.

Motor Type | Compatible Stator Options | Compatible Rotor Options | Typical Applications |

Three Phase Induction (IEC/NEMA) | Distributed windings, skewed slots, vent ducts | Squirrel cage (Al/Cu), skewed bars, balanced with shaft | Pumps, fans, compressors, conveyors |

Single Phase Induction | Split phase/PSC/cap start slot forms | Squirrel cage rotor | Appliances, HVAC blowers |

BLDC (Inner Rotor) | Concentrated windings, tooth skew, low cogging designs | SPM/IPM with retention sleeve | Robotics, power tools, drones |

BLDC (Outer Rotor) | Thin yoke, high slot fill | Magnetized rotor can with adhesive/pocket retention | HVAC EC fans, e bikes |

PMSM/Servo | Distributed or concentrated windings; low harmonic loss laminations | IPM/SPM, precision balance | Automation, machine tools |

Switched Reluctance (SRM) | Segmented stators, robust tooth tips | Salient rotors, optimized for low acoustic noise | Pumps, harsh environments |

- If your design is not listed, send drawings or a sample; we can reverse engineer geometry and material stack ups.

Typical Technical Specifications

These values reflect our standard manufacturing envelope for build-to-print or design-to-spec stators and rotors. We routinely deliver outside these ranges with engineering review.

Parameter | Ranges |

Stator OD | 20–1,000 mm |

Stack Length | 10–500 mm |

Lamination Thickness | 0.20–0.65 mm |

Slot Count | 6–72 (higher on request) |

Rotor Balance | ISO 21940 G2.5 (tighter available) |

Insulation Class | F (155 °C) / H (180 °C) |

Magnet Types | NdFeB (N35–N52, M/SH/…); SmCo |

Die-Cast Cages | Aluminum or Copper |

Air-Gap Concentricity | ≤ 0.02–0.05 mm (design dependent) |

Voltage/Frequency | Global (50/60 Hz) & inverter duty |

How We Manufacture Stator and Rotor?

- We produce motor stator and rotor through a precision-controlled workflow, ensuring consistency, performance, and reliability across every stage.

- Mold Design & Engineering: Develop precision stamping die designs based on prototype feedback and required lamination tolerances.

- Lamination Stamping: High-speed presses stamp laminations with precise tolerances and smooth edges.

- Core Stacking: Align and stack laminations accurately to ensure magnetic uniformity and core strength.

- Heat Treatment: Apply thermal processing to relieve stress and enhance material magnetic properties.

- Insulation Coating: Coat slots and surfaces to provide strong dielectric protection and heat resistance.

- Coil Winding: Use automated winding systems to ensure consistent coil density and electrical accuracy.

- Impregnation and Curing: Vacuum-pressure resin impregnation enhances insulation reliability and mechanical stability.

- Dynamic Balancing: Balance cores precisely to minimize vibration and ensure smooth motor operation.

- Quality Inspection: Perform detailed dimensional and electrical testing to meet international quality standards.

Quality & Inspection

- From raw steel to finished cores, we verify every step with measurable controls, documented traceability, and compliance.

- Incoming Materials: Grade/lot verification for electrical steel and magnets.

- In-process: Burr height control, stack factor/height monitoring, interlock integrity, casting fill verification.

- Final: CMM for critical features, rotor dynamic balance, hi-pot/insulation checks on winding-ready stators, surface-finish inspection.

- Documentation: Control plans, inspection reports, and serialization/traceability available upon request.

- Standards: ISO 9001 / IATF 16949 capable, PPAP, RoHS/REACH compliance. (UL 1446 insulation systems available when specified.)

Customer Case

- Customer: A leading European e-bike brand upgrading its mid-drive motor platform.

- Challenge: Deliver a quieter ride, stronger hill-start torque, and a drop-in fit to the existing motor envelope and mounting points.

Our Solution

- Stator: 0.27 mm skewed laminations (48-slot) with an optimized slot/pole combination to suppress torque ripple and acoustic tones.

- Rotor: Surface-mounted N48SH magnets for stable high-temperature performance.

- Balance & NVH: Rotors balanced to ISO 21940 G2.5 to cut vibration-induced noise.

- Durability & Compliance: VPI impregnation for winding robustness; coatings are RoHS/REACH-compliant.

- Drop-in Fit: Maintained original outer diameter, stack length, and mounting interfaces to avoid frame changes.

Results

Parameter | Customer Requirement | Delivered Result |

Power Class | 250–500 W | Meets 250/500 W SKUs |

Efficiency | ≥ 89% peak | 91.2% (↑ ~2.4 pts) |

Acoustic Noise | Quieter than current model | −3.8 dBA at 25 km/h |

Start-up Torque | Higher on 10% grade | ↑ 12% vs. baseline |

Freewheel Drag | Minimize | ↓ 15% at 30 km/h |

Insulation/Finish | Class H; compliant coatings | Class H; RoHS/REACH OK |

General FAQs

Do you supply assembled stator/rotor or components only?

Both. Options range from laminated stacks to fully wound/impregnated stators and balanced rotors with shafts and sleeves.

What materials are available for motor stator and rotor?

Electrical steel grades 35–65, amorphous options, copper or aluminum die-cast cages, NdFeB or SmCo magnets, stainless or aluminum carriers, and class F/H compatible varnishes and adhesives.

Do you support design-to-spec projects for motor stator and rotor solutions?

Yes. We co-develop electromagnetic layouts, manufacturability, thermal paths, cost targets; deliver DFM/DFMEA, prototypes, validation reports, rapid iterations until specifications are consistently achieved.

Can you support rapid prototyping for new motor stator and rotor designs?

Yes. We cut prototype laminations, assemble stacks, machine rotors, magnetize in-house, enabling electromagnetic iterations before committing to progressive dies, tooling, and capex.

How do you control lamination burrs on motor stators to reduce core loss?

We monitor burr height, maintain tooling, apply deburring, and validate stack factor to minimize interlaminar shorts and losses for consistent magnetic performance.