The manufacture of lamination stack assemblies is crucial in the electric motor industry. Whether for industrial motors or electric vehicles, lamination stacks significantly impact motor performance, efficiency, and reliability.

Even small errors in material selection or assembly can cause inefficiencies, higher losses, and reduced service life, leading to costly repairs and warranty claims.

Inadequate Material Selection and Poor Handling Practices

Material selection is crucial in producing effective lamination stacks. Electrical steel and magnetic alloys must have uniform thickness, consistent magnetic properties, and proper insulation coatings to prevent energy-losing eddy currents.

Choosing substandard materials, often due to cost pressures or poor supplier vetting, can lead to defects that are hard to fix later. Low-quality laminations with inconsistent grain structures, coatings, or thicknesses increase core losses and reduce motor efficiency, torque, and reliability.

Proper handling of materials before and during assembly is crucial. Exposure to moisture, dust, oils, and contaminants can cause oxidation, surface defects, and weakened insulation, degrading magnetic performance and leading to uneven stacking, misalignment, and motor core issues.

Best Practices:

- Establish strict incoming inspection standards for material dimensions, coatings, and chemical composition.

- Store laminations in controlled environments with regulated humidity and clean air conditions.

- Limit physical handling; use clean gloves and dedicated storage racks to reduce surface contamination.

Improper Stamping Techniques and Tooling Errors

The precision of stamping operations directly determines the geometric and magnetic integrity of individual laminations. Incorrect punching processes, worn dies, or poorly maintained stamping presses can produce irregular edges, burrs, or variations in shape that inhibit proper stacking.

Laminations with burrs, sharp edges, or inconsistent dimensions are harder to align, creating air gaps, misfits, and mechanical stresses. These defects disrupt magnetic flux and increase core losses. Additionally, poorly maintained tooling causes uneven wear and quality drift over time, even if initial calibrations were correct.

In stamping operations, common issues include:

- Excessive burr formation: This occurs when punch-to-die clearances are not tailored to material thickness, or tooling is not kept sharp. Burrs can catch on adjacent laminations and make stacking inconsistent.

- Edge fractures and cracking: Inadequate press settings or worn tooling also contribute to small cracks or fractures around perforations and slot cutouts.

Best Practices:

- Employ precision tooling calibrated to the specific steel grade and lamination thickness.

- Maintain tooling schedules that include regular sharpening and wear assessments.

- Use automated stamping systems where possible to reduce variation caused by manual operations.

Insufficient Quality Control and Inspection Procedures

Even when materials and tooling are up to standard, inadequate quality control can allow critical defects to slip through. A lamination stack’s integrity depends on hundreds or thousands of individual parts meeting exacting tolerances. Without robust inspection procedures, small deviations compound into significant performance issues.

Inspections should go beyond visual checks to include dimensional metrology, stack height validation, and tests for burr height and alignment. Non-destructive techniques like eddy current or ultrasonic testing are essential for detecting hidden flaws, such as microcracks or internal deformations, before assembly.

Faulty or infrequent testing often manifests in the field as:

- Increased heat generation due to uneven magnetic flux.

- Mechanical noise because of misaligned laminations.

- Shortened insulation life and early failure.

Best Practices:

- Define checkpoints throughout the production process, not only at the end.

- Implement real-time monitoring technologies that detect deviations immediately.

- To spot trends and proactively address underlying causes, employ statistical process control, or SPC.

Poor Process Optimization and Parameter Management

Manufacturers often overlook the need for consistent process parameters across batches. Stamping force, press speeds, and stacking pressures must be optimized, as small variations can cause structural inconsistencies in the assembled core.

In stamping, not adjusting parameters for coil weights or steel thickness can cause edge distortions or uneven burr heights. In stacking, variations in sequence, compression, or environmental conditions (e.g., temperature, humidity) can affect core density and magnetic performance.

Even factors like thermal expansion during press operations, which may seem minor, can introduce cumulative dimensional errors when not standardized or compensated for in machine settings.

Best Practices:

- Establish and document optimized process parameters for each material and design specification.

- Use automated control systems to enforce consistency across shifts and production runs.

- Conduct periodic audits of machine calibration and performance data.

Poor Cooperation and Communication with Important Stakeholders

Manufacturing lamination stacks involves multiple teams, including engineering, production, quality assurance, and material suppliers. Miscommunication might result in mistakes or inefficiency when these teams operate in silos.

For instance, if engineering updates a lamination design but production isn’t informed, tooling may produce outdated parts. Similarly, if suppliers aren’t part of the feedback loop, they may deliver material lots with inconsistent coating thicknesses.

These gaps in communication not only lead to direct manufacturing errors but also complicate traceability—making defect resolution slower and more costly.

Best Practices:

- Use centralized platforms for documentation, revisions, and production notes accessible to all relevant teams.

- Engage suppliers early in specification development and feedback loops.

- Hold regular interdisciplinary meetings to align on priorities and address emerging issues.

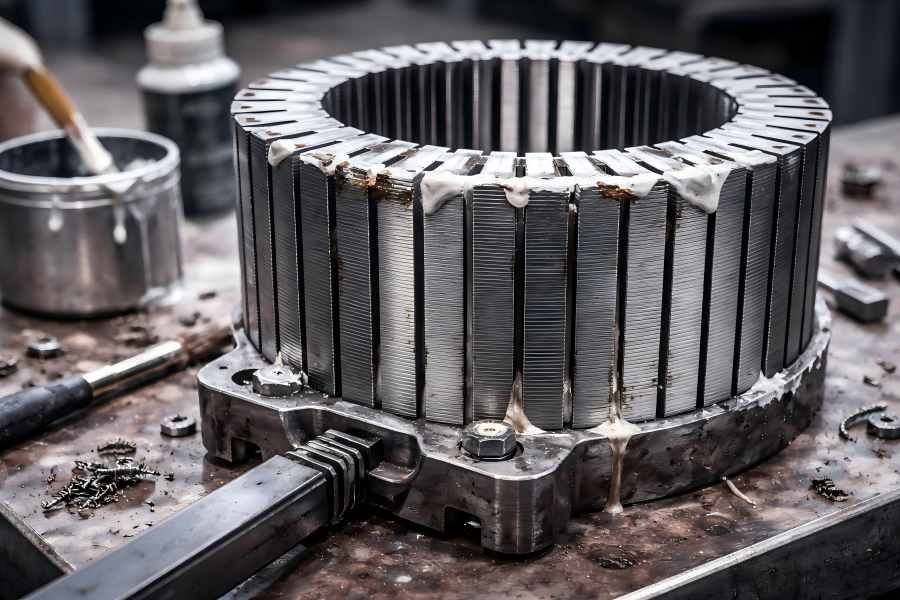

Neglecting Core Bonding, Stacking Integrity, and Post-Assembly Stability

The final mistake concerns post-assembly bonding and core integrity. Once laminations are stacked, they must be bonded, welded, or mechanically secured to form a stable core.

Poor bonding leads to weak mechanical integrity, allowing vibration, thermal cycling, or magnetic forces to cause slippage or delamination, which reduces motor efficiency and may lead to early failure. Bonding issues are worsened when environmental factors like humidity or temperature extremes are not considered.

Typical causes of bonding failures include:

- Use of low-quality adhesives or bonding materials.

- Misaligned lamination layers that prevent full contact between surfaces.

- Inadequate compression during bonding that fails to remove microvoids between laminations.

Best Practices:

- Choose bonding agents and methods that are appropriate for the motor’s working environment.

- Ensure lamination surfaces are clean and properly aligned prior to bonding.

- Integrate post-assembly checks such as vibration testing and thermal cycling to validate bond strength.