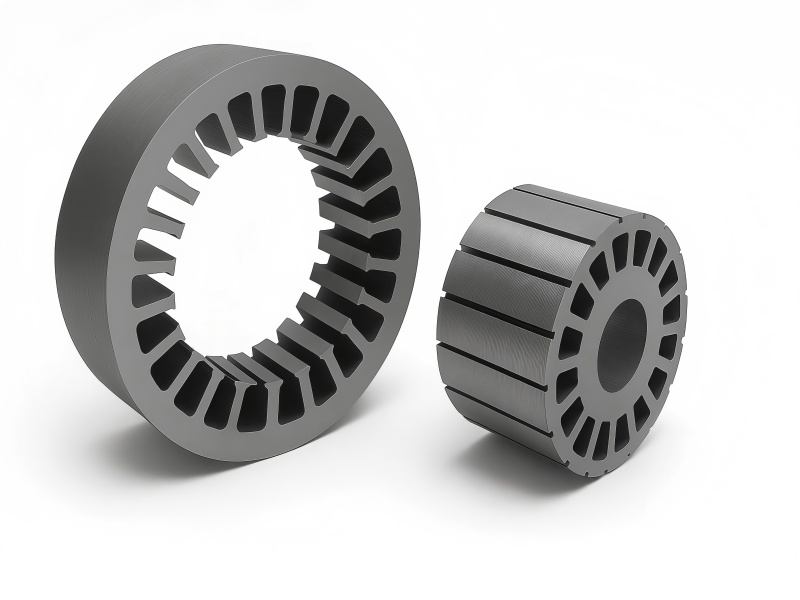

EV Motor Core

- Material Flexibility: Nickel alloy, cobalt alloy, and silicon steel for customized performance.

- Thin Lamination Design: 0.2–0.35 mm sheets minimize eddy-current loss at high speeds.

- Tight Dimensional Tolerance: ±0.01 mm ensures concentric assembly and quiet operation.

- High Power Density: ≥ 4.0 kW/kg enables compact, lightweight EV drive systems.

- Noise Reduction: Optimized skew angle reduces torque ripple and NVH levels.

Technical Specifications

| Parameter | Specification |

| Material | Non-oriented Silicon Steel / Nickel Alloy / Cobalt Alloy |

| Lamination Thickness | 0.2 – 0.35 mm |

| Outer Diameter (Stator) | 80 – 600 mm |

| Outer Diameter (Rotor) | 60 – 550 mm |

| Stack Height | Customizable |

| Flux Density | ≥ 1.7 T |

| Core Loss | ≤ 1.5 W/kg @ 400 Hz |

| Operating Temperature | –40 °C ~ +200 °C |

| Motor Type | PMSM / Induction / Hybrid Traction Motor |

| Applications | EV / Hybrid Motor / E-Axle / E-Drive Systems |

Customization & OEM Service

- Design stator/rotor geometry for specific EV motor architectures (PMSM, IPM, or induction).

- Choose material grades for desired efficiency, flux, and frequency range.

- Offer welded, bonded, or interlocked lamination stacks.

- Provide electromagnetic and thermal simulation during prototype development.

- Support small-batch sampling for testing and mass production readiness.

- Offer OEM logo engraving, labeling, and export packaging.

Applications Fields

- Electric passenger vehicles (EV & HEV)

- Commercial and logistics e-trucks

- Electric buses and construction vehicles

- E-axle and integrated drive units

- High-performance electric sports vehicles

Production Process

Advanced Workshop