Today, electric motors are used in almost all modern machines—from robots and home appliances to airplanes and factory equipment. They change electrical energy into movement, powering both simple and complex systems.

For engineers, knowing different motor types is very important. The motor they choose affects energy use, load support, speed, torque, noise, control, and how long a product lasts. Choosing the wrong motor can cause problems, increase costs, or waste energy.

As industries aim for better performance and smarter systems, picking the right motor has become more challenging. Engineers must understand how each motor works, how it’s made, and the pros and cons. This helps them build reliable and efficient machines.

How Electric Motors Work: A Quick Refresher

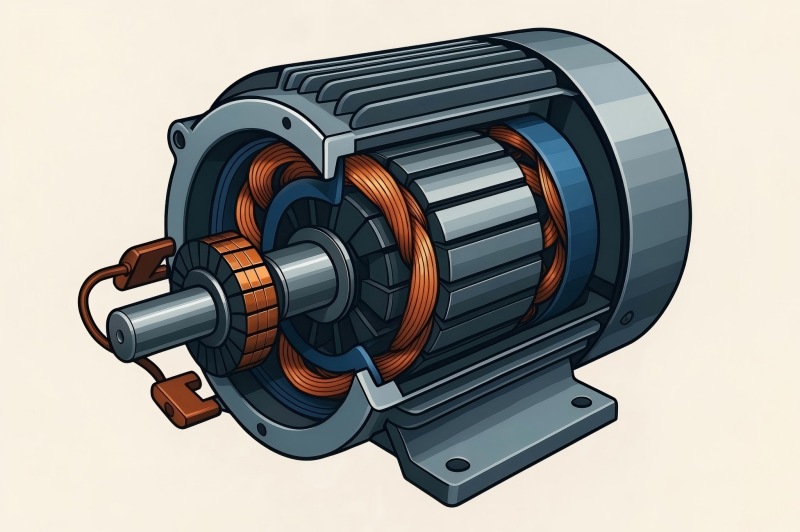

An electric motor primarily uses the principles of electromagnetism to transform electrical energy into mechanical energy. According to the Lorentz force law, a current-carrying conductor experiences a force when it is positioned inside a magnetic field. In a motor, this force is converted into rotation.

Electric motors typically have two essential components:

- Stator: The stationary part, often consisting of wire windings or permanent magnets, that generates a magnetic field.

- Rotor: The revolving part that acquires torque as a result of its interaction with the stator’s magnetic field.

Motors use either AC or DC current to create a magnetic field, depending on their type. Some motors use brushes and commutators to switch current, while others use electronic controllers.

The rotor keeps spinning by switching magnetic poles around it. More sophisticated motors employ feedback mechanisms for accurate control, such as resolvers or encoders. Each motor type has different efficiency, speed, and torque, so understanding how they work is important for choosing the right one.

Electric motor classification: AC vs. DC

Electric motors are broadly classified into two fundamental categories based on the power supply type:

AC Motors (Alternating Current)

These motors are powered by an alternating current that changes direction periodically. AC motors are the backbone of industrial machinery and household appliances because they are efficient, low-maintenance, and well-suited for high-power applications.

AC Motor Types:

- Induction Motors (Asynchronous)

- Synchronous Motors

- Linear AC Motors

DC Motors (Direct Current)

DC motors operate on unidirectional current and offer excellent speed control and torque at low RPM. Applications needing fast dynamic reaction and changeable speed frequently use them.

DC Motors Types:

- Brushed DC Motors

- DC motors without brushes (BLDC))

- Universal Motors (work on both AC and DC)

This basic classification provides the foundation for understanding all other motor subtypes. The core differences between AC and DC motors lie in their construction, control methods, and applications, as we’ll explore in the next sections.

AC Motors Explained

AC motors dominate the industrial world due to their simplicity, durability, and ability to handle large-scale operations. They are driven by alternating current and can be sub-categorized into synchronous and asynchronous (induction) motors.

Induction Motors

Induction motors—often called asynchronous motors—are the most widely used AC motors. The way they operate is based on electromagnetic induction, in which the rotor receives electricity from the stator’s revolving magnetic field.

Key Characteristics:

- Rugged and simple design

- Low maintenance (no brushes or commutators)

- Cost-effective

Types of Induction Motors:

- Squirrel Cage Motors: Most common, reliable, and suitable for fixed-speed applications.

- Wound Rotor Motors: Allow external resistance to be added, useful for variable-speed and high-torque startups.

Applications:

- Pumps, compressors, conveyors, HVAC systems, and fans.

Synchronous Motors

Synchronous motors rotate at the same frequency as the AC power supply. The rotor is magnetized using either permanent magnets or DC excitation.

| Pros | Cons |

| Constant speed under varying loads | Require precise control during startup |

| Higher efficiency than induction motors | More expensive and complex |

| Capable of power factor correction |

Applications:

High-precision industrial drives, robotics, and power factor correction applications in power systems.

DC Motors Explained

DC motors provide excellent controllability and are ideal for applications requiring speed variation, rapid starts, and torque control. The defining feature is their ability to convert DC electricity directly into mechanical motion.

Brushed DC Motors

These motors maintain rotation by reversing the armature windings’ current flow using brushes and a commutator.

| Pros | Cons |

| Simple control | Brush and commutator wear over time |

| High starting torque | More frequent maintenance |

| Low cost | Electrical noise due to arcing |

Applications:

Electric toys, automotive seat actuators, wiper systems, and small appliances.

Brushless DC Motors (BLDC)

BLDC motors replace the mechanical commutator with an electronic controller that uses sensors to detect rotor position and switch current accordingly.

| Pros | Cons |

| High efficiency and power density | Requires a controller |

| Quiet and reliable operation | More expensive than brushed DC motors |

| Minimal maintenance |

Applications:

- Electric vehicles, drones, HVAC compressors, robotics, and computer cooling systems.

How Do Brushless and Brushed Motors Differ?

The debate between brushed and brushless motors often comes down to cost, control complexity, and application requirements. Here’s a quick comparison:

| Feature | Brushed DC Motor | Brushless DC Motor (BLDC) |

| Commutation | Mechanical (brushes) | Electronic (controller) |

| Maintenance | High (brush wear) | Low |

| Efficiency | Moderate | High |

| Noise | Higher | Lower |

| Cost | Low | Higher |

| Lifespan | Shorter | Longer |

| Control Complexity | Simple | Advanced |

| Applications | Low-power, cost-sensitive | High-efficiency, dynamic |

BLDC motors are clearly superior in most performance metrics, but brushed motors remain popular where budget and simplicity take priority.

Stepper Motors: Accurate Management in Individual Steps

Stepper motors are a unique kind of brushless motor that rotates continuously but moves in discrete increments. Each input pulse moves the rotor a fixed angle, making them perfect for open-loop position control.

Stepper motor types include:

- Permanent Magnet Stepper

- Variable Reluctance Stepper

- Hybrid Stepper (most popular)

How They Work:

When a pulse is applied, the stator creates a magnetic field that aligns the rotor with one of its teeth. By sequencing these pulses across multiple windings, the rotor advances step by step.

| Pros | Cons |

| No feedback required (open-loop) | Resonance at certain speeds |

| Excellent low-speed torque | Lower efficiency than BLDC motors |

| Simplified control with digital pulses | Potential for missed steps under load |

Applications:

- Textile machines, CNC machines, 3D printers, and automated camera systems.

Modern stepper motor controllers often use microstepping to achieve smoother motion and reduce vibration, blurring the line between stepper and servo systems in terms of performance.

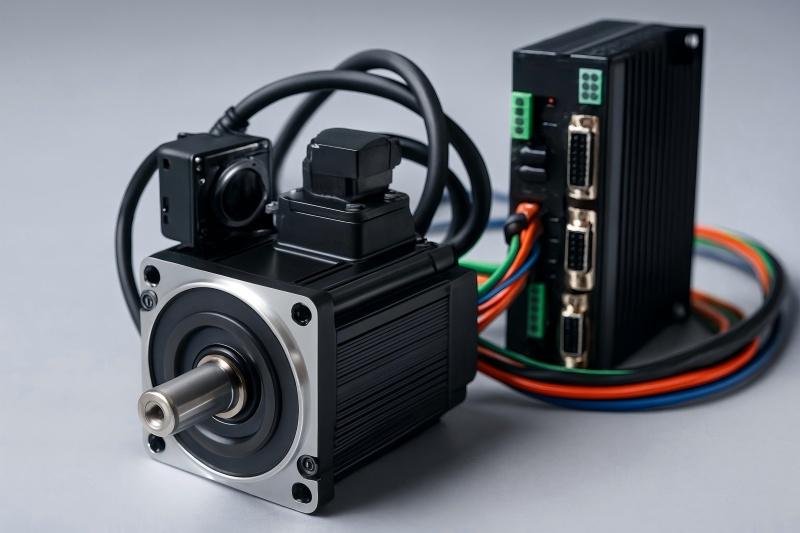

Servo Motors: Feedback-Controlled Performance

Servo motors are made for uses where precise control over acceleration, speed, and angular or linear position is necessary. Unlike open-loop motors like stepper motors, servo systems are closed-loop—they incorporate feedback mechanisms (typically encoders or resolvers) to constantly monitor and correct motion.

Types of Servo Motors:

- AC Servo Motors: Widely used in industrial automation due to their high efficiency and speed range.

- DC Servo Motors: Simpler but limited in power and scalability.

- Brushless Servo Motors: Combine BLDC design with integrated feedback for high performance.

Core Components:

- Motor (AC or DC)

- Controller (PID or advanced digital)

- Feedback Device (e.g., optical encoder)

- Power Supply

| Pros | Cons |

| High torque-to-inertia ratio | More complex and expensive |

| Smooth and precise operation | Requires tuning (PID parameters) |

| Fast response to dynamic loads | Sensitive to electrical noise and feedback failure |

| High efficiency and low noise |

Applications:

- Industrial robotics, CNC machinery, packaging lines, camera gimbals, medical imaging systems, and aerospace actuators.

Servo motors are critical when accuracy, real-time control, and reliability are non-negotiable.

Linear Motors: Direct Drive for Specialized Applications

Electrical energy is directly transformed into linear motion by linear motors, which eliminate the need for mechanical transmission systems like belts or lead screws or rotating parts. They’re essentially unrolled rotary motors.

Types of Linear Motors:

- Linear Induction Motor (LIM): Works like a flat induction motor.

- Linear Synchronous Motor (LSM): Often uses permanent magnets on the mover and energized windings in the stator.

Operating Principle:

The stator creates a moving electromagnetic field that pushes or pulls the mover along a straight path. Because there’s no contact, wear and mechanical backlash are minimized.

| Pros | Cons |

| Ultra-precise positioning and high acceleration | Higher cost |

| No mechanical coupling = less maintenance | Cooling challenges at high power |

| Faster reaction times | Requires specialized control and alignment |

Applications:

- Semiconductor fabrication, maglev trains, laser cutting machines, wafer inspection, and automated testing equipment.

Linear motors are ideal where frictionless high-speed movement and sub-millimeter positioning are essential.

Switched Reluctance Motors: Rugged and Efficient

Switched Reluctance Motors (SRMs) have emerged as strong contenders in harsh environments due to their simple yet highly efficient design. They work by moving the rotor to a position where the magnetic reluctance is as low as possible.

Key Characteristics:

- Rotor: Laminated steel with no windings or magnets

- Stator: Energized sequentially using a controller

- Controller: Switches the stator windings at specific rotor positions

| Pros | Cons |

| High efficiency, especially at low and mid-range speeds | Torque ripple and acoustic noise |

| Extremely robust (no rotor windings or magnets) | Complex control requirements |

| Withstands high temperatures | Less torque density compared to BLDC motors |

| Low production cost (magnet-free) |

Applications:

- Electric vehicles, heavy-duty washing machines, mining equipment, wind turbines, and aerospace systems.

With advancements in control algorithms and materials, SRMs are now viable for applications where durability and cost-effectiveness outweigh ultra-smooth motion.

Universal Motors: High-Speed Operation Across AC and DC

Electric motors with series windings that run on either AC or DC power are known as universal motors. They are lightweight, high-speed, and capable of delivering significant torque.

Construction:

- Series-wound field coils

- Commutator and brushes

- Iron core armature

Key Features:

- Operates well on both AC and DC

- Compact and inexpensive

- Capable of very high RPMs (up to 20,000)

| Pros | Cons |

| High starting torque | Brush wear and electrical noise |

| Simple speed control using voltage variation | Lower efficiency and shorter lifespan |

| Low cost and easy to manufacture | Not suitable for continuous-duty operation |

Applications:

- Sewing machines, hair dryers, vacuum cleaners, portable power tools, and kitchen equipment including mixers and blenders.

Despite their shortcomings, universal motors remain indispensable in consumer products where short bursts of high-speed power are needed.

Key Factors in Motor Selection: Torque, Speed, and Efficiency

Selecting a motor that “fits” your application is only one aspect of choosing the proper one. Engineers must balance a variety of design parameters to match performance requirements, environmental constraints, control complexity, and cost.

Torque Requirements

- Starting Torque: Essential for overcoming inertia.

- Running Torque: Must be sufficient for continuous load.

- Peak Torque: Determines overload handling capacity.

High-torque applications such as electric vehicles or elevators demand motors with robust startup capabilities, like DC or SRMs.

Speed and Acceleration

- Low-speed motors: Offer higher torque but limited RPM.

- High-speed motors: Prioritize rapid motion, ideal for fans and turbines.

- Acceleration rate: Servo and linear motors are ideal for applications requiring sharp dynamic response.

Efficiency

The amount of electrical energy that is transformed into mechanical work depends on efficiency. Factors affecting efficiency include:

- Winding resistance and core losses

- Friction and air gap width

- Thermal dissipation

- Commutation losses (in brushed motors)

Duty Cycle

- Continuous (S1): Motor runs at a steady load indefinitely.

- Intermittent (S3): Regular start-stop operation.

- Short-time (S2): Motor operates for a fixed short duration and cools off.

Matching the duty cycle to motor type ensures thermal balance and prolongs lifespan.

Size, Weight, and Mounting

- Compact motors (e.g., BLDC or stepper) are better for mobile robots and drones.

- Heavy-duty motors (e.g., induction or SRMs) suit industrial environments.

Control Complexity

- Open-loop systems (e.g., stepper motors) require less control.

- Closed-loop systems (e.g., servos) provide higher accuracy but demand sensors and tuning.

Cost and Availability

Cost varies with motor type, material, controller requirements, and manufacturing scale. For instance:

- Universal motors are cheap and widely available.

- BLDC motors require investment in controllers and sensors.

A well-informed selection process minimizes design risks, optimizes performance, and improves ROI.

Industry Applications of Different Motor Types

Electric motors are embedded in every sector of industry, from microelectronics to megawatt-scale infrastructure. Their selection is influenced by industry-specific needs like robustness, precision, weight, and regulatory compliance.

Automotive

- BLDC Motors: Used in electric vehicle propulsion, power steering, HVAC.

- SRMs: Emerging in EVs due to magnet-free, rugged design.

- Stepper Motors: Control dials, headlight positioning, mirror adjustment.

Aerospace and Defense

- Servo Motors: Actuators in aircraft wings, drones, targeting systems.

- Linear Motors: Used in aircraft launch systems (EMALS).

- BLDC Motors: Cooling fans in avionics, UAV propulsion.

Manufacturing and Automation

- AC Induction Motors: Conveyor belts, pumps, compressors.

- Servo Motors: CNC machinery, packaging lines, pick-and-place robots.

- Stepper Motors: 3D printers, textile machinery, dispensing systems.

Medical Devices

- Brushless DC Motors: Surgical robots, ventilators, infusion pumps.

- Servo Motors: MRI table adjustment, prosthetics.

- Stepper Motors: Peristaltic pumps, positioning tables.

Home and Consumer Appliances

- Universal Motors: Mixers, vacuums, drills.

- BLDC Motors: Washing machines, HVAC compressors, ceiling fans.

Renewable Energy

- Synchronous Motors: Wind turbine generators.

- BLDC Motors: Solar tracker actuators.

| Industry | Preferred Motor Types | Common Applications |

| Automotive | BLDC, SRM, Stepper | EV drive, mirrors, infotainment systems |

| Aerospace | Servo, BLDC, Linear | UAVs, actuators, cooling systems |

| Manufacturing | Induction, Servo, Stepper | Robotics, CNC, compressors |

| Consumer Goods | Universal, BLDC | Hairdryers, washing machines, kitchen appliances |

| Medical | BLDC, Servo, Stepper | Ventilators, prosthetics, lab automation |

| Energy | Synchronous, BLDC, Linear | Turbines, solar tracking, grid-tied generators |

Advances in Motor Technology and Smart Integration

As industries undergo digital transformation, electric motors are no longer standalone components—they are now smart, connected, and integrated into intelligent systems.

Smart Motors and IoT Integration

Motors equipped with embedded sensors (temperature, vibration, position) can feed real-time data to centralized control systems. This enables:

- Predictive maintenance

- Remote diagnostics

- Load monitoring

- Cloud-based performance analytics

Advanced Materials

- Rare-earth magnets (NdFeB) in BLDC motors increase torque density.

- Soft magnetic composites (SMCs) reduce core losses.

- Carbon fiber rotors reduce weight and improve response in servo systems.

Controller Advancements

Modern motor drives support:

- Real-time feedback processing (Field Oriented Control)

- Adaptive tuning via AI algorithms

- Energy recovery systems in regenerative braking

Integration with Industry 4.0 and AI

Motors are becoming active participants in automated factories, working in tandem with AI to:

- Optimize energy consumption dynamically

- Reroute production in response to supply chain changes

- Learn optimal motion profiles through machine learning

Sustainability and Green Tech

- High-efficiency motors (IE4, IE5) reduce global electricity demand.

- Recyclable materials and modular design are now favored.

- Hydrogen fuel cell systems paired with electric motors are under active development for trucks and aviation.

3D Printing and Customization

With additive manufacturing, you can:

- Lighter, more compact rotor and stator designs

- Custom slot and winding configurations

- Rapid prototyping of novel geometries

These advancements position electric motors at the center of innovation in the electrified, autonomous, and sustainable future.