Induction motors power everything from household appliances to large industrial systems. Among the key design elements affecting their performance, rotor configuration determines load behavior, efficiency, torque, and durability.

The two main types — die-cast (squirrel cage) and wound rotor — each offer distinct structures, advantages, and application scopes. Selecting the right one requires balancing performance, maintenance, cost, and control needs.

Fundamentals of Rotor Construction

The induction motor rotor is the rotating component of an induction motor, responsible for converting electrical energy into mechanical torque. Because of its position inside the stator, a revolving magnetic field is created, causing the rotor conductors to conduct electricity.

There are two principal types of rotors:

- Die-Cast (Squirrel Cage) Rotor: Consists of aluminum or copper bars short-circuited by end rings, forming a cage-like structure. The entire assembly is embedded into laminated steel cores and cast as one piece.

- Wound Rotor: Contains three-phase insulated windings, much like those in the stator, which are linked to external resistances through slip rings and brushes. The external resistances allow control of the rotor current and torque characteristics during startup and operation.

While both designs are based on the same electromagnetic induction principle, their structural and operational differences lead to vastly different performance behaviors.

Die-Cast Rotor Design

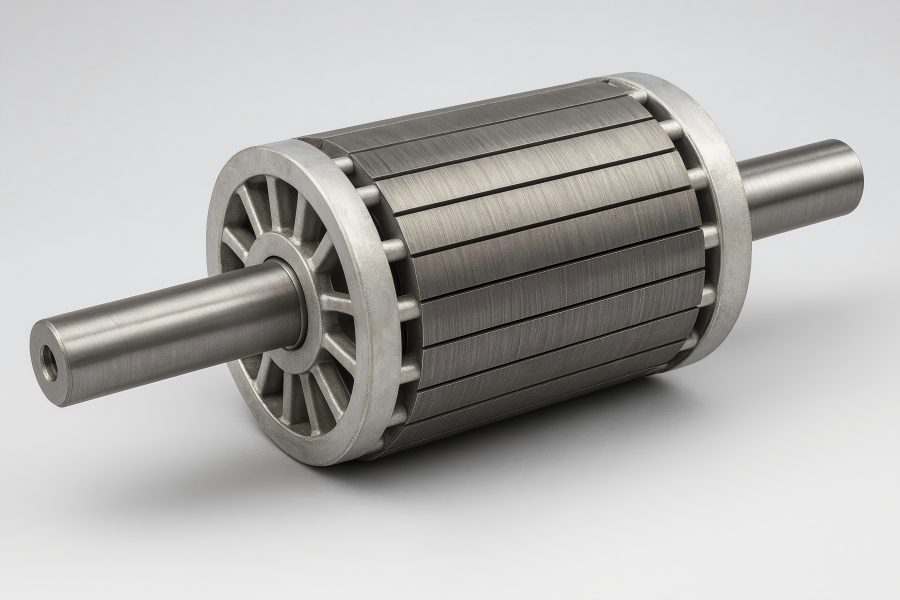

The die-cast rotor, also known as the squirrel cage rotor, is the most common type used in standard induction motors.

Construction

A shaft is crushed with a stack of laminated steel sheets to form the rotor. Conductive bars — typically aluminum or copper — are cast into the slots of the laminations and short-circuited by end rings. Modern die-casting technology enables excellent dimensional accuracy and thermal contact between the conductors and the core, improving efficiency.

Advantages

- Simplicity and Reliability: With no brushes or slip rings, die-cast rotors are nearly maintenance-free.

- Durability: The solid structure resists mechanical and electrical stress, ideal for continuous-duty operation.

- Cost-Effective Manufacturing: High-volume production through pressure die-casting makes these rotors economical.

- Good Efficiency: Especially in high-quality copper die-cast rotors, efficiency can exceed 92–94% for industrial motors.

Limitations

- Fixed speed: Torque and speed characteristics cannot be adjusted externally.

- High initial current: usually five to seven times the current that is rated.

- Lower starting torque compared with wound rotors.

Typical Applications

- Die-cast rotors are widely used in:

- Fans and blowers

- Pumps and compressors

- Conveyors and HVAC systems

- Machine tools and mixers

Wound Rotor Design

The wound rotor motor, also known as the slip-ring induction motor, uses a more complex rotor construction that allows control over speed and torque during operation.

Construction

The rotor carries three-phase insulated windings, each connected to slip rings mounted on the shaft. Brushes contact these slip rings, connecting them to an external resistance bank. Adjusting the resistance changes the current and torque behavior of the rotor circuit.

Advantages

- High Starting Torque: The motor can generate two to three times the starting torque of a squirrel cage motor by adding external resistance.

- Low Starting Current: The additional resistance limits current draw during startup, protecting the supply network.

- Variable Speed Control: Varying the external resistance enables smooth speed adjustment without complex drives.

- Soft Starting: Reduces mechanical shock on belts, gears, and couplings.

Limitations

- Requires periodic maintenance (brush and slip-ring wear).

- More expensive due to complex design.

- Lower efficiency if operated continuously with resistance inserted.

Common Applications

- Wound rotor motors are preferred in:

- Cranes and hoists (high starting torque)

- Mills and crushers (variable load)

- Elevators and conveyors

- Mixers and winches

Performance Comparison

Key performance characteristics are compiled in the following table to help you better understand their differences:

| Parameter | Die-Cast Rotor Motor | Wound Rotor Motor |

| Construction | Solid cage with shorted bars | Insulated windings connected via slip rings |

| Starting Torque | Moderate | High (adjustable) |

| Starting Current | High | Controlled by external resistance |

| Speed Control | Fixed | Adjustable through resistance |

| Efficiency | High (fixed) | Variable (slightly lower under resistance) |

| Maintenance | Minimal | Requires brush/slip-ring upkeep |

| Cost | Lower | Higher initial cost |

| Typical Applications | Pumps, fans, compressors | Cranes, mills, hoists |

Energy Efficiency and Material Considerations

Efficiency has become a key design factor due to global energy regulations (e.g., IE3, IE4, and IE5 standards). The rotor’s material choice directly influences electrical losses and thermal management.

Copper vs. Aluminum Die-Cast Rotors

Aluminum is cost-effective and lighter but has higher electrical resistance.

Copper offers better conductivity (about 60% lower resistivity), improving motor efficiency by up to 2–5%.

However, copper die-casting requires higher temperatures and more precise mold control, raising manufacturing costs.

Thermal Performance

Copper’s superior conductivity enhances heat dissipation, reducing rotor temperature and extending bearing life. For high-efficiency industrial motors, copper die-cast rotors are increasingly favored.

Wound Rotor Efficiency

In wound rotor motors, efficiency varies with resistance insertion. At full load (when resistance is shorted), the efficiency can approach that of a die-cast motor. However, during partial-load or variable-speed operation, energy losses in the resistor bank can reduce overall performance.

Material and Efficiency Comparison

| Rotor Type | Material | Conductivity (% of Cu) | Thermal Conductivity (W/m·K) | Relative Efficiency Impact |

| Die-Cast Aluminum | Al | ~61% | ~237 | Baseline |

| Die-Cast Copper | Cu | 100% | ~401 | +2–5% higher |

| Wound Rotor | Cu Windings | 100% | ~401 | Variable (depends on resistance setting) |

Choosing the Right Motor for Your Application

Selecting between die-cast and wound rotor designs depends on your application’s mechanical load, duty cycle, and control needs. Below is a practical guide:

| Application | Preferred Rotor Design | Justification |

| Fans and Pumps | Die-Cast | Fixed speed, low torque start |

| Compressors | Die-Cast | Constant load, low maintenance |

| Cranes and Hoists | Wound Rotor | High starting torque required |

| Mills and Crushers | Wound Rotor | Variable load, torque control |

| Elevators | Wound Rotor | Smooth start, adjustable speed |

| HVAC Systems | Die-Cast | Reliable and energy-efficient operation |

Decision Factors

- Load Characteristics: Heavy starting loads favor wound rotors.

- Control Requirements: Need for speed control without electronics? Choose wound rotors.

- Maintenance Resources: If minimal maintenance is desired, die-cast rotors are best.

- Budget: Die-cast motors have a lower upfront cost, but wound rotors offer operational flexibility that may justify the expense.

- Energy Policy: For continuous duty and efficiency compliance, copper die-cast rotors are increasingly preferred.

Manufacturing and Quality Control

Rotor manufacturing precision directly affects motor performance, vibration, and reliability.

Die-Cast Rotor Production

- Core Preparation: Laminated silicon steel sheets are pressed and aligned.

- Die-Casting: Molten aluminum or copper is injected under high pressure to form the cage.

- Cooling and Finishing: Controlled cooling ensures minimal voids or shrinkage defects.

- Balancing and Testing: Dynamic balancing and electrical continuity checks ensure smooth operation.

Advanced CNC and robotic casting systems ensure consistent quality for mass production.

Wound Rotor Manufacturing

- Slot Insulation: Rotor slots are insulated to prevent short circuits.

- Coil Winding: Copper windings are precisely wound and connected to slip rings.

- Varnish Impregnation: Enhances insulation and vibration resistance.

- Testing: High-voltage insulation, resistance balance, and dynamic performance are verified.

In both cases, quality control — including eddy-current testing, runout measurement, and CTE matching between rotor and shaft — ensures mechanical stability and efficiency.