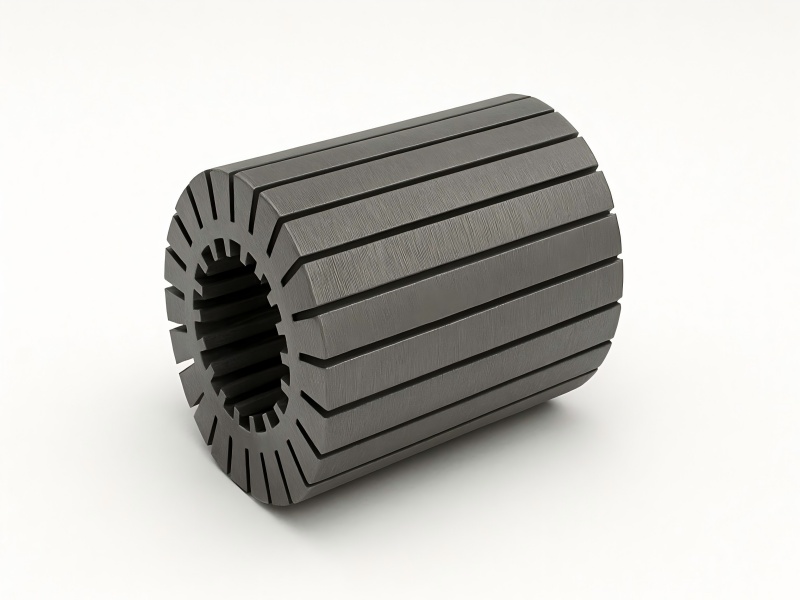

DC Motor Rotor Core

- Material Composition: High-grade silicon steel laminations with magnetic permeability ≥ 1.8 T for enhanced flux density.

- Burr Height Control: Maintained ≤ 0.02 mm to minimize short-circuit risk and improve rotor balance.

- Commutator Fit: Engineered slot geometry supports optimal brush contact and current distribution.

- Customization Range: Outer diameter 10 mm – 200 mm, stack height per drawing, and multiple slot configurations available.

Technical Specifications

| Parameter | Specification Range |

| Material | Silicon Steel / Iron Alloy |

| Lamination Thickness | 0.1 – 0.5 mm |

| Outer Diameter | 10 – 200 mm |

| Stack Height | Customizable |

| Slot Type | Straight / Skewed |

| Burr Height | ≤ 0.02 mm |

| Manufacturing Process | Precision Stamping / Laser Cutting |

| Rotor Type | Wound Armature / PMDC Rotor |

| Tolerance | ± 0.02 mm |

| Application | DC Motors for Automotive, Tools, Robotics |

| Quality Standard | ISO9001 / IATF16949 Certified |

Customization & OEM Service

- Material selection based on flux density and cost.

- Slot number and angle optimization.

- Core geometry and commutator seat design per customer drawings.

- Insulation coating and lamination bonding options.

- Prototype to mass-production support with PPAP documentation.

Application Fields

- Automotive Systems: Window lift, wiper, and seat adjustment motors.

- Industrial Tools: Drills, saws, and grinders.

- Household Appliances: Mixers, fans, and cleaning equipment.

- Robotics & Automation: Servo arms, actuators, and drives.

- Medical Devices: Small pumps and motion modules.

Production Process

Advanced Workshop