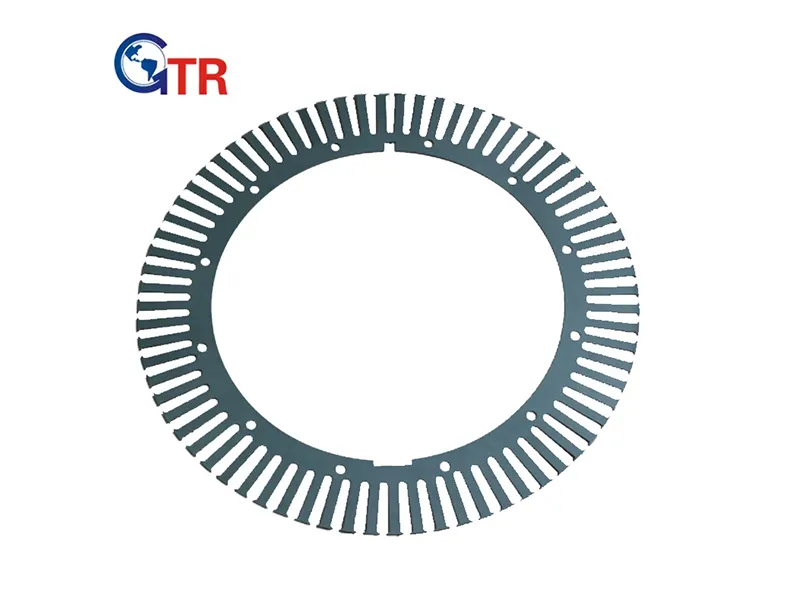

BLDC Stator Lamination

- High Magnetic Efficiency: Minimizes core loss for smooth motor operation.

- Precision Stamping: Ensures tight dimensional tolerance and low burr levels.

- Material Variety: Available in high-grade silicon steel and nickel alloys.

- Customizable Designs: Tailored slot shapes and lamination dimensions for various BLDC applications.

- Size Range: Custom outer diameters from 30 mm – 500 mm.

Technical Specifications

| Parameter | Specification |

| Material | Silicon Steel, Nickel Alloy |

| Thickness | 0.1 mm – 0.5 mm |

| Outer Diameter | 30 mm – 500 mm |

| Inner Diameter | Customizable |

| Insulation Coating | C5, C6, or customer-specified |

| Tolerance | ±0.01 mm |

| Application | BLDC Motors for Robotics, HVAC, EVs, Drones |

Customization & OEM Service

- Custom lamination geometry according to CAD drawings.

- Progressive die and compound die stamping options.

- Material grades and insulation coatings selectable.

- Laser cutting for prototypes or small batches.

- Stack bonding: welding, riveting, or adhesive bonding available.

- OEM & ODM branding support.

Applications

- Robotics and Automation

- Electric Vehicles (EV/HEV)

- Drones and UAVs

- HVAC and Pumps

- Industrial Fans and Compressors

Production Process

Advanced Workshop