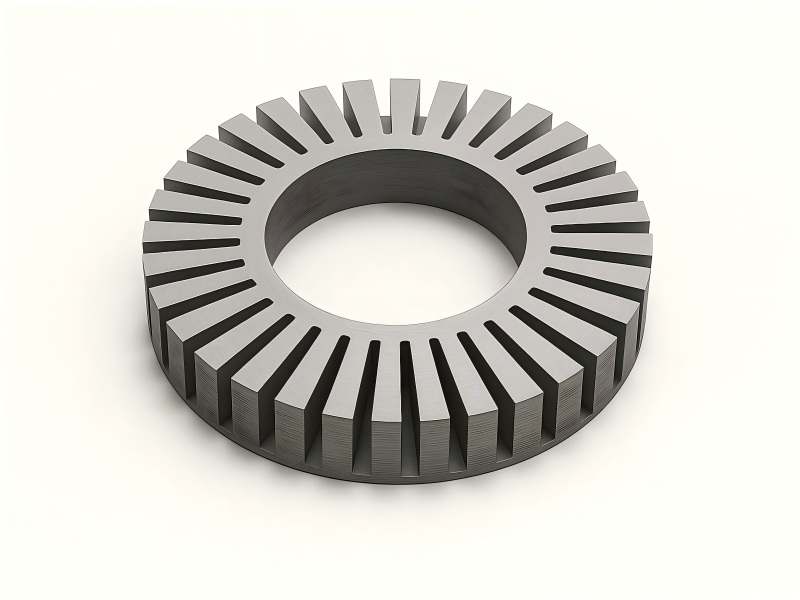

Axial Flux Motor Stator

- Material Options: Non-oriented silicon steel / amorphous / cobalt alloy laminations.

- Ultra-Thin Laminations: 0.1–0.3 mm to minimize eddy-current loss in high-speed operation.

- High Torque Density: Delivers up to 30% more torque per volume than radial flux designs.

- Compact & Lightweight: 50% reduction in length compared to conventional stators.

- Custom Coil Geometry: Optimized slot layout for hairpin or flat wire windings.

Technical Specifications

| Parameter | Specification |

| Material | Non-oriented Silicon Steel / Amorphous / Cobalt Alloy |

| Lamination Thickness | 0.1 – 0.3 mm |

| Outer Diameter Range | 50 – 500 mm |

| Inner Diameter Range | Customizable |

| Stack Height | 5 – 100 mm |

| Magnetic Flux Density | ≥ 1.7 T |

| Core Loss | ≤ 1.5 W/kg @ 400 Hz |

| Operating Temperature | –40 °C ~ +180 °C |

| Coil Type | Round / Flat / Hairpin |

| Applications | EVs / Aerospace / Robotics / Compact Drives |

Customization & OEM Service

- Customize outer/inner diameter, thickness, and lamination shape for axial flux design.

- Select optimal material grade and coating for frequency and loss requirements.

- Offer laser bonding, interlocking, or adhesive stacking options.

- Provide 3D simulation for flux path and torque optimization.

- Support prototype to mass production for automotive and aerospace projects.

- Include laser marking, batch traceability, and export packaging.

Application fields

- Electric vehicles (in-wheel and traction motors)

- Drones and unmanned aerial vehicles (UAVs)

- Aerospace propulsion systems

- Robotics and automation drives

- Compact industrial motors

Production Process

Advanced Workshop