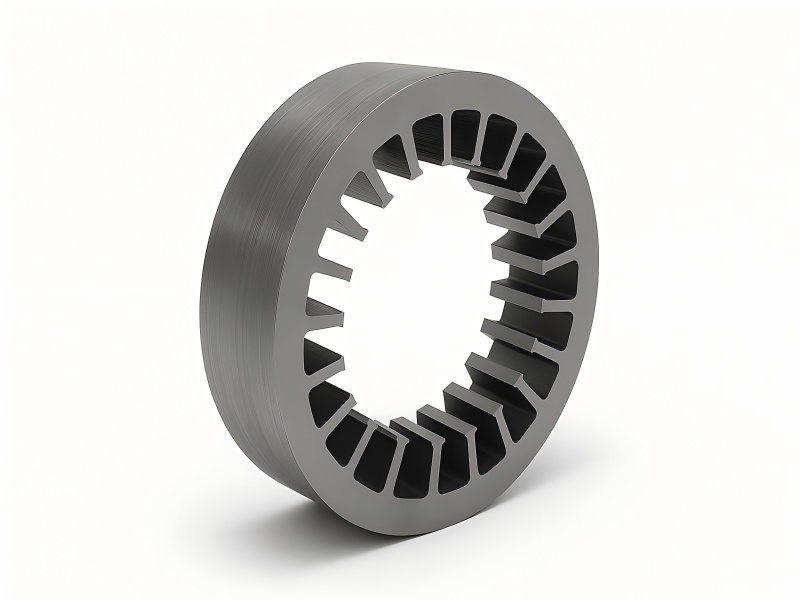

Alternator Stator Core

- High Magnetic Efficiency: Flux density ≥ 1.7 T supports stable current generation and high electrical output.

- Precision Lamination Alignment: ≤ 0.03 mm deviation maintains flux uniformity and voltage stability.

- Wide Frequency Adaptability: Effective performance from 50 Hz to 400 Hz for automotive and generator systems.

- Thermal Endurance: Operates up to 200 °C, suitable for high-speed alternators and demanding environments.

- Corrosion Protection: Epoxy insulation coating prevents oxidation and extends lifespan.

Technical Specifications

| Parameter | Specification |

| Material | Non-oriented Silicon Steel / Cobalt Alloy |

| Lamination Thickness | 0.2 – 0.5 mm |

| Outer Diameter Range | 50 – 800 mm |

| Stack Height | Customizable |

| Flux Density | ≥ 1.7 T |

| Core Loss | ≤ 2.0 W/kg @ 50 Hz |

| Operating Frequency | 50 – 400 Hz |

| Operating Temperature | –40 °C ~ +200 °C |

| Assembly Method | Interlocked / Welded / Bonded |

| Applications | Automotive Alternators / Industrial Generators / Wind Turbine Alternators |

Customization & OEM Service

- Design core diameter, stack height, and slot geometry based on alternator specifications.

- Select material grade and coating type according to frequency and power requirements.

- Provide interlocked, bonded, or welded stacking based on mechanical strength needs.

- Offer small-batch prototypes for high-speed generator testing.

- Support automotive, industrial, and renewable alternator standards.

- Provide OEM engraving, labeling, and anti-corrosion packaging.

Application Fields

- Automotive alternators and hybrid charging systems

- Industrial generator sets and standby power units

- Wind turbines and renewable energy alternators

- Marine and aviation generator systems

- High-speed brushless alternators

Production Process

Advanced Workshop