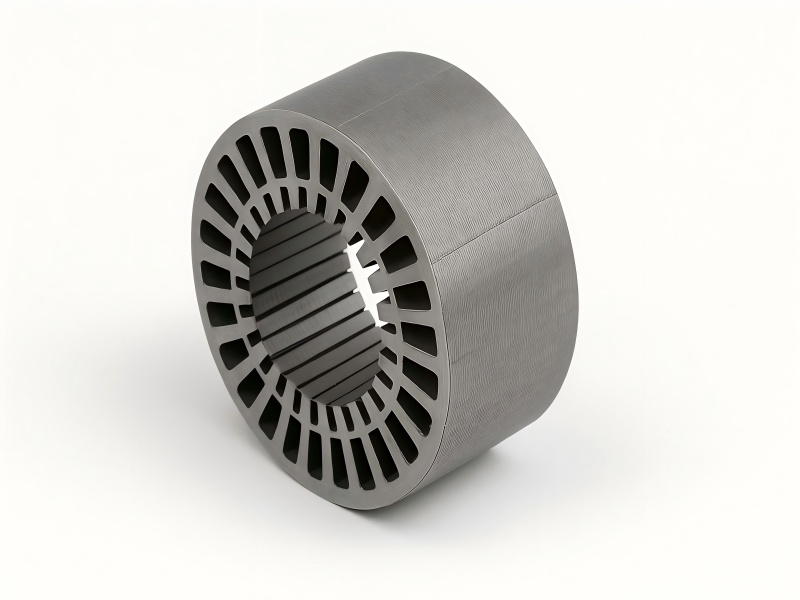

AC Motor Rotor Core

- Material Options: Non-oriented silicon steel (35A300–50W470) or cobalt alloy for high-efficiency AC systems.

- Low Iron Loss: ≤ 2.0 W/kg @ 50 Hz, improving motor efficiency under alternating load.

- High Magnetic Saturation: Flux density ≥ 1.6 T supports strong torque output without saturation distortion.

- Precision Slot Geometry: Slot tolerance ± 0.01 mm ensures uniform air-gap and torque balance.

- Surface Smoothness: Rotor OD roughness ≤ 0.8 μm ensures efficient magnetic coupling with stator.

Technical Specifications

| Parameter | Specification |

| Material | Non-oriented Silicon Steel / Cobalt Alloy |

| Lamination Thickness | 0.2 – 0.5 mm |

| Outer Diameter Range | 30 – 600 mm |

| Stack Height | Customizable |

| Rotor Type | Squirrel Cage / Wound / Solid |

| Flux Density | ≥ 1.6 T |

| Core Loss | ≤ 2.0 W/kg @ 50 Hz |

| Balancing Accuracy | ≤ G2.5 |

| Operating Temperature | –40 °C ~ +180 °C |

| Applications | AC Induction Motors / Synchronous Motors / High-speed Drives |

Customization & OEM Service

- Design outer/inner diameters and slot shapes for specific torque-speed profiles.

- Choose lamination materials and thickness for target efficiency class.

- Offer welded, bonded, or interlocked stack options for different load conditions.

- Provide prototypes for performance testing and validation.

- Support balancing and core assembly with shaft integration.

- Offer custom marking, coating, and export packaging.

Application Fields

- Three-phase AC induction motors

- Synchronous and high-speed AC motors

- HVAC compressors and industrial fans

- Electric vehicle traction motors

- Pumps, conveyors, and automation drives

Production Process

Advanced Workshop