Electric vehicles (EVs), which offer improved energy efficiency and a smaller environmental effect, are revolutionizing contemporary transportation.

However, ensuring their long-term performance requires proper maintenance of critical components, especially the motor rotor—a key element in converting electrical energy into mechanical motion. To maximize rotor lifespan and vehicle efficiency, EV owners should follow best maintenance practices.

Understanding the Role of Motor Rotors in EVs

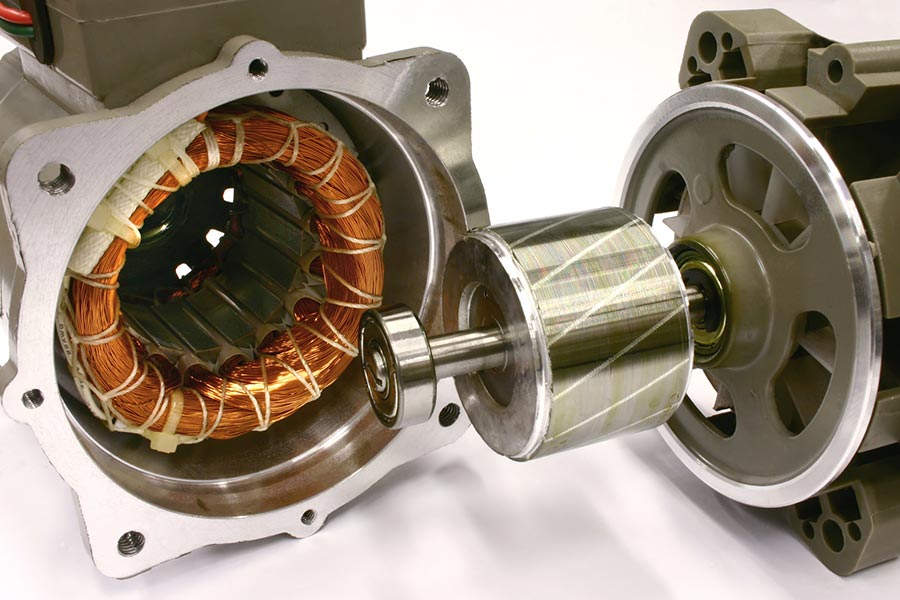

The motor rotor is a crucial part of an EV’s electric motor, working alongside the stator to generate torque and power the vehicle. In electric vehicles, motor rotors come in two main varieties:

- Permanent Magnet Synchronous Motor (PMSM) Rotors: These rely on strong rare-earth magnets, offering high efficiency and power density but requiring protection against heat-induced demagnetization.

- Induction Motor Rotors: Common in some EVs, these rotors use electromagnetic induction instead of permanent magnets, making them durable but requiring proper cooling and maintenance.

Regardless of the motor type, regular maintenance ensures rotor efficiency, longevity, and smooth vehicle performance. Neglecting maintenance can lead to overheating, increased friction, insulation damage, and premature failure, impacting both performance and cost.

Key Maintenance Tips for Long-lasting EV Motor Rotors

1. Maintain Optimal Operating Temperatures

One of the main factors threatening the longevity of motor rotors is heat. Excessive temperatures can cause insulation breakdown, magnet demagnetization (in PMSMs), and reduced efficiency. To prevent overheating:

- Ensure Proper Cooling System Functionality: Liquid-cooled and air-cooled EV motors rely on thermal management systems. Keep the cooling system, including the heat exchangers and coolant levels, inspected and maintained on a regular basis.

- Monitor Temperature Sensors: Most EVs are equipped with built-in thermal sensors. Drivers should frequently check temperature readings through the vehicle’s onboard diagnostics system.

- Avoid Rapid Acceleration and Braking: Aggressive driving generates excess heat, putting stress on the motor rotor. A smoother driving style helps maintain consistent temperatures.

- Keep Ventilation Paths Clean: For air-cooled motors, blocked air vents reduce heat dissipation, increasing thermal stress on the rotor.

2. Regularly Inspect and Lubricate Bearings

Bearings are responsible for ensuring smooth rotor rotation and reducing friction. Without proper lubrication, increased wear and misalignment can occur, leading to vibration and efficiency losses. Follow these best practices:

- Use Manufacturer-Specified Lubricants: Applying the correct lubricant prevents excessive friction and wear.

- Check for Unusual Noises or Vibrations: Sudden noises may indicate bearing failure, requiring immediate inspection.

- Follow Lubrication Intervals: Avoid over-lubrication or under-lubrication, both of which can negatively affect bearing performance.

3. Prevent Contamination and Moisture Damage

The insulation integrity and motor rotor balance can be significantly impacted by contaminants including dust, dirt, and moisture. Corrosion and short circuits are common issues resulting from improper sealing. To prevent contamination:

- Regularly Inspect Motor Seals: Ensure that motor housing and protective enclosures are intact and sealed properly.

- Store EVs in Dry Environments: High humidity levels can accelerate insulation degradation and lead to moisture-related failures.

- Avoid Driving Through Deep Water: While most EVs are designed with water-resistant motors, prolonged exposure to water can still cause damage.

- Clean Ventilation Openings: Remove dust accumulation in air-cooled motors to maintain airflow and prevent overheating.

4. Check Electrical Connections and Insulation Integrity

Electrical faults can cause increased resistance, overheating, and loss of motor efficiency. To guarantee correct operation:

- Examine the connectors and wiring: Inefficiencies can result from increased electrical resistance caused by loose or corroded connections.

- Check for Insulation Degradation: Damaged insulation may lead to short circuits or reduced performance. Any signs of cracks or wear should be addressed immediately.

- Follow Manufacturer Voltage Ratings: Avoid exceeding the recommended voltage range, which can put excessive stress on the rotor.

5. Ensure Proper Rotor Balancing and Alignment

Rotor imbalance leads to excessive vibrations, which can result in mechanical wear, bearing damage, and reduced motor efficiency. To prevent these issues:

- Schedule Periodic Rotor Balancing Tests: Regular balancing inspections help detect and correct misalignments before they escalate.

- Monitor Vibration Levels: Sudden increases in vibration could indicate a rotor imbalance issue, requiring immediate correction.

- Address Any Rotor Shaft Misalignment: Misaligned shafts increase mechanical stress, reducing the rotor’s lifespan.

6. Optimize Driving Habits for Rotor Longevity

The way an EV is driven has a direct impact on the motor rotor’s durability. To extend rotor lifespan:

- Avoid Hard Acceleration and Braking: Sudden power demands increase thermal and mechanical stress on the rotor.

- Use Regenerative Braking Moderately: While regenerative braking helps conserve energy, excessive reliance creates torque fluctuations, affecting rotor stability.

- Minimize High-Speed Driving: Sustained high-speed operation increases rotor stress, leading to premature wear.

7. Adhere to Manufacturer Maintenance Schedules

EV manufacturers provide detailed maintenance schedules to optimize motor performance and extend rotor life. Following these schedules ensures:

- Routine Service Checks Are Performed: Early detection of rotor issues prevents costly repairs.

- Timely Component Replacement: Bearings, lubricants, and insulation materials have finite lifespans and should be replaced on time.

- Motor Control Software Updates: Software-controlled motor optimizations improve efficiency and prevent unnecessary stress on rotor components.

8. Maintain Proper Load and Torque Distribution

Unbalanced loads and torque fluctuations place additional strain on the rotor. Best practices include:

- Ensuring Even Weight Distribution in the Vehicle: Uneven weight affects torque application, increasing rotor wear.

- Avoiding Overloading the EV: Carrying excessive loads increases mechanical and thermal stress on the motor rotor.

- Maintaining Proper Torque Settings: Sudden torque surges can accelerate rotor fatigue, leading to early failure.

9. Keep Motor Control Systems Updated

Modern EV motors rely on intelligent control systems to optimize performance. Keeping software and control algorithms updated helps:

- Ensure Efficient Power Delivery: Prevents excessive rotor stress by optimizing energy distribution.

- Monitor Error Codes in Real Time: Many EVs have built-in diagnostics systems that alert users to motor-related issues.

- Enhance Overall Motor Performance: Software optimizations prolong rotor life by reducing unnecessary wear and energy losses.

Conclusion

A well-maintained motor rotor is key to ensuring long-term EV performance and reliability. By monitoring temperatures, preventing contamination, lubricating bearings, and optimizing driving habits, EV owners can significantly extend rotor lifespan. Proper care minimizes breakdowns, enhances energy efficiency, and ensures a smooth driving experience in the evolving world of electric mobility.