Motor & Generator Cores for Aerospace

- Our motor and generator cores for aerospace applications meet rigorous aviation standards, ensuring high precision, durability, and efficiency.

- Designed for extreme conditions, they ensure reliable performance in high altitudes, temperature shifts, and strong vibrations, maintaining stability in aerospace systems.

Motor & Generator Cores for the Aerospace Market

- The aerospace market demands motor and generator cores with high precision, lightweight materials, and superior thermal stability to operate in extreme conditions.

- Our advanced stator and rotor core solutions meet strict aerospace standards, ensuring optimal performance for aircraft, satellites, and space exploration.

Using high-performance materials and precise manufacturing, Gator provides cores with reduced electromagnetic losses and improved energy efficiency. Our aerospace expertise ensures reliable, durable core solutions that meet the industry’s evolving needs.

Our Solutions for Aerospace Applications

Motor and generator cores play a pivotal role in aerospace, enhancing power efficiency, weight optimization, and operational reliability. They are widely used in the following applications:

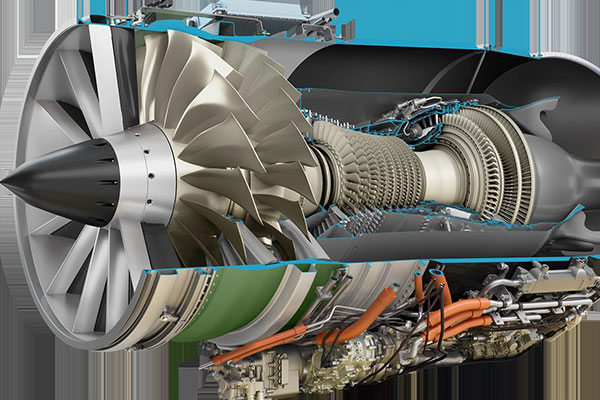

Electric Propulsion Systems

Motor cores are used in electric motors that power propellers or fans in electric or hybrid-electric aircraft.

Auxiliary Power Units (APUs)

Generator cores are used in APUs to provide auxiliary electrical power for systems like lighting, avionics, and environmental controls.

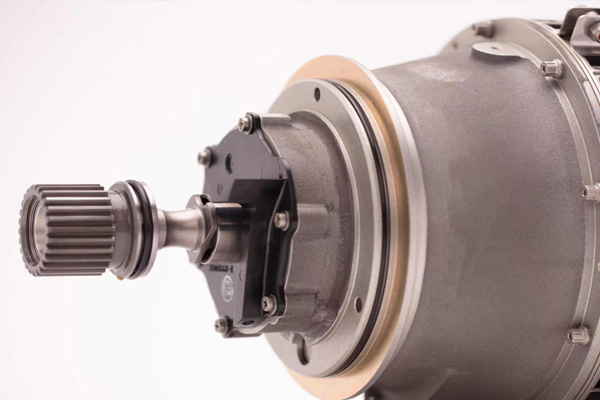

Starter Generators

These combine motor and generator functions, using cores to start the main engines and generate power once the engines are running.

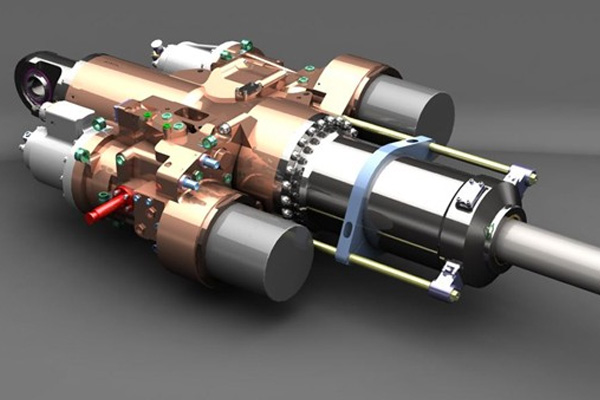

Flight Control Actuators

Motor cores are used in electric actuators that control flight surfaces such as ailerons, rudders, and elevators.

Environmental Systems

Motors with cores are used in systems like cabin air circulation fans and cooling pumps.

Landing Gear Systems

Electric motors with cores may be used in retraction and extension mechanisms for landing gear.

General FAQs

Can your aerospace motor cores be customized?

Yes, they can be customized based on specific aerospace application requirements, including size, power output, and integration needs.

What is the efficiency of your motor cores?

Aerospace motor cores are engineered for high efficiency, typically exceeding 90%, to minimize energy loss and improve the overall performance and longevity of aerospace systems.

What materials do you use in aerospace motor and generator cores?

Aerospace motor and generator cores typically use high-performance alloys, such as silicon steel, cobalt alloys, and advanced composites, for durability and reliability in extreme conditions.

What standards do your aerospace motor and generator cores meet?

They are made to adhere to strict aerospace standards, such as ASTM, ISO, and military requirements, guaranteeing dependability, efficiency, and security.

What testing is required for your motor cores?

Testing includes high-temperature endurance tests, vibration analysis, electrical performance testing, and long-term operational simulations.