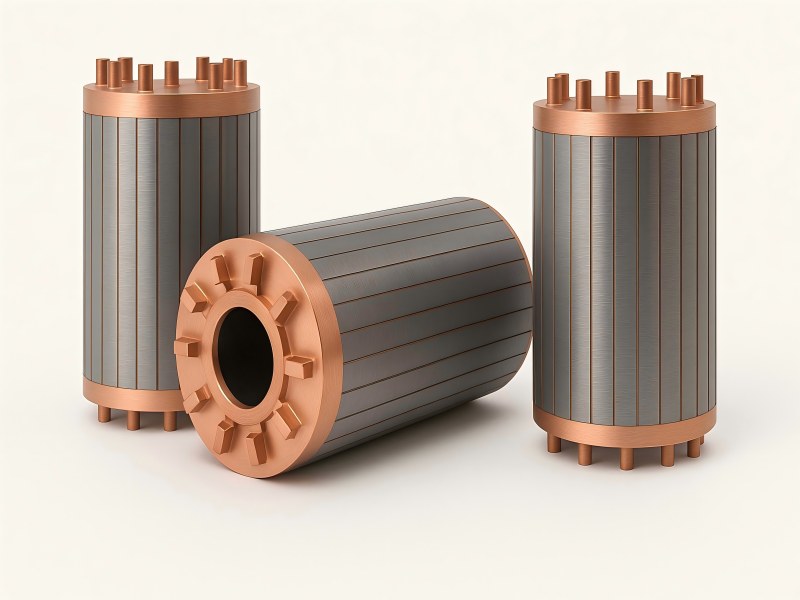

Copper Die Casted Rotor

- Superior Conductivity: Copper’s 58 MS/m conductivity boosts motor efficiency by 15–20% over aluminum rotors.

- Lower Rotor Resistance: Reduces I²R loss, improving torque output and reducing operational temperature.

- Precision Casting Quality: Vacuum or high-pressure die-casting ensures full slot fill with minimal porosity.

- Enhanced Motor Efficiency: Enables IE4 and IE5 class performance in industrial applications.

- Eco-Friendly & Recyclable: 100% copper rotor reduces lifecycle carbon footprint.

Technical Specifications

| Parameter | Specification |

| Material | Pure Copper (≥ 99.9%) / Non-oriented Silicon Steel |

| Casting Process | Vacuum / High-Pressure Die-Casting |

| Lamination Thickness | 0.3 – 0.5 mm |

| Outer Diameter | 30 – 600 mm |

| Stack Height | 10 – 500 mm |

| Electrical Conductivity | ≥ 58 MS/m |

| Core Loss | ≤ 2.0 W/kg @ 50 Hz |

| Operating Temperature | –40 °C ~ +220 °C |

| Dynamic Balance | ≤ G2.5 ISO |

| Applications | IE4/IE5 Motors / EV Traction / HVAC / Compressors / High-Speed Drives |

Customization & OEM Service

- Design rotor cage geometry for target torque and efficiency levels.

- Choose copper grades or coatings for corrosion protection and oxidation resistance.

- Support vacuum or pressure die-casting options.

- Provide custom balancing and insulation treatments.

- Offer simulation and prototyping for energy-efficient motor design.

- Deliver OEM labeling, batch tracking, and export-ready packaging.

Application Fields

- High-efficiency industrial induction motors (IE4/IE5)

- Electric vehicles and hybrid traction motors

- HVAC compressors and blower drives

- Industrial fans, pumps, and automation motors

- Precision CNC and inverter-duty drives

Production Process

Advanced Workshop