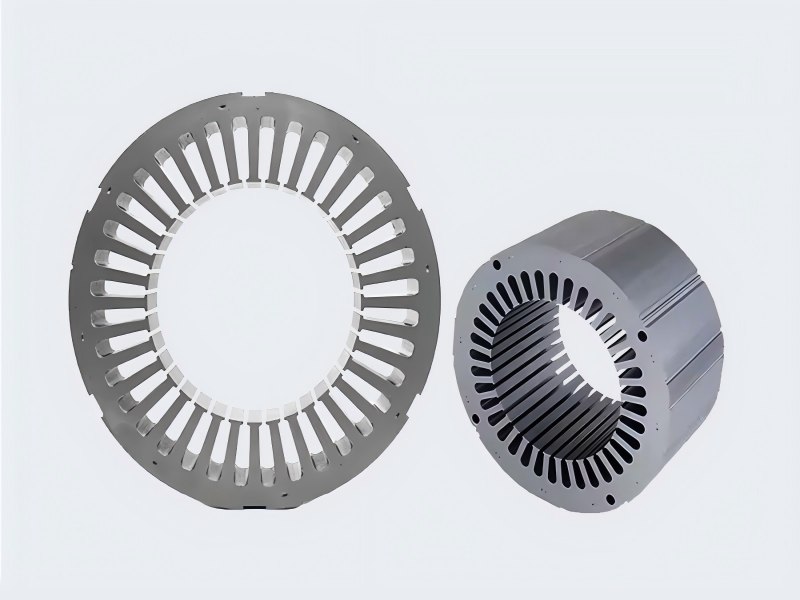

Induction Motor Stator Core

- Dimensional Precision: ±0.01 mm tolerance ensures consistent coil fitting and low vibration during rotation.

- Thermal Endurance: Suitable for heavy-load and continuous-duty applications, it can withstand temperatures as high as 180 °C.

- Optimized Slot Geometry: Improves electromagnetic balance and reduces winding copper loss.

- Strong Lamination Bonding: Stacking alignment error ≤ 0.03 mm for better magnetic uniformity.

- Corrosion Resistance: Long-term defense against oxidation and moisture is offered by a dual-layer epoxy insulating coating.

Technical Specifications

| Parameter | Specification |

| Material | Non-oriented Silicon Steel / Cobalt Alloy |

| Lamination Thickness | 0.2 – 0.5 mm |

| Outer Diameter Range | 60 – 1000 mm |

| Stack Height | 20 – 600 mm |

| Slot Type | Open / Semi-closed |

| Core Loss | ≤ 2.0 W/kg @ 50 Hz |

| Operating Temperature | –40 °C to +180 °C |

| Stacking Method | Interlocked / Bonded / Welded |

| Applications | Pumps, Compressors, HVAC, Industrial Motors, EV Auxiliary Systems |

Customization & OEM Service

- Design stator dimensions and slot geometry according to motor drawings.

- Select silicon steel grades and insulation coatings for specific efficiency classes (IE2–IE4).

- Choose stacking method: interlocked, bonded, or welded depending on production scale.

- Provide lamination thickness optimization for loss reduction and cost control.

- Support OEM requirements including custom labeling, part coding, and export packaging.

Application Fields

- Industrial water pumps and compressors

- HVAC and refrigeration motors

- Conveyors, elevators, and drive systems

- Mining and agricultural machinery

- Electric vehicle auxiliary motors (fan and pump drives)

- Generators and alternators

Production Process

Advanced Workshop