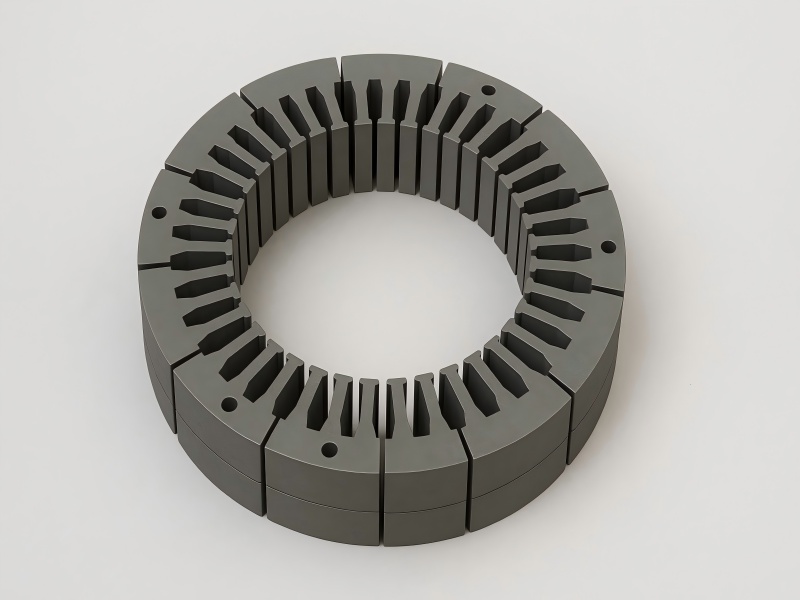

Segmented Stator Core

- High Magnetic Efficiency: Core loss ≤ 2.2 W/kg @ 50 Hz ensures optimal motor efficiency.

- Reduced Eddy Current Loss: Laminations insulated with epoxy or phosphate coatings lower losses by 5–8 %.

- Easy Assembly Design: Modular arc-segment configuration simplifies automated and manual assembly.

- Flexible Motor Integration: Suitable for both inner and outer rotor structures.

- Custom Segment Count: Adjustable number of slots and poles to fit compact or large-diameter motors.

Technical Specifications

| Parameter | Specification |

| Material | Silicon Steel / Nickel Alloy / Cobalt Alloy |

| Lamination Thickness | 0.1 – 0.5 mm |

| Outer Diameter Range | 30 – 800 mm |

| Segment Count | 6 – 36 (customizable) |

| Stacking Method | Welding / Bonding / Interlocking |

| Application | EV, Servo, Robotics, Wind, HVAC Motors |

| Core Loss | ≤ 2.2 W/kg @ 50 Hz |

| Tolerance | ± 0.01 mm |

Customization & OEM Service

- Tailor segment shape, slot count, and outer diameter according to motor specifications.

- Choose lamination materials, thickness, and insulation coating based on motor type.

- Adjust segment curvature and stacking height for various rotor sizes.

- Offer bonding, interlocking, or welding assembly options.

- Provide OEM logo engraving and customized export packaging.

Application Fields

- Electric vehicle traction motors

- Industrial servo motors and drives

- Robotics and automation actuators

- Wind turbine generator motors

- High-speed compressors and HVAC systems

- Aerospace and defense motion systems

Production Process

Advanced Workshop