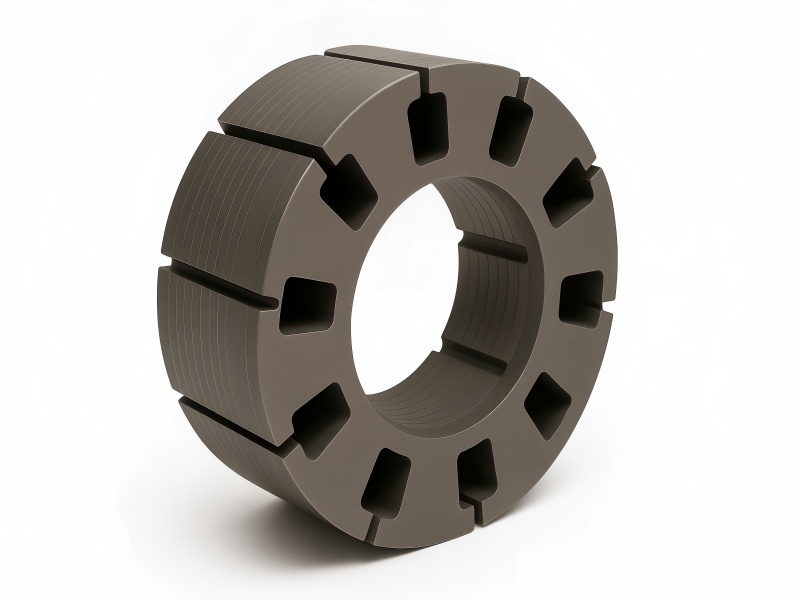

Servo Motor Rotor Core

- Tight Tolerance Accuracy: ± 0.01 mm dimensional precision guarantees balanced rotation and stable servo response.

- Low Inertia Design: Lamination stack reduces rotational inertia 8–12 % for faster start–stop performance.

- Material Options: Silicon steel (35A300–50W470), nickel–iron, or cobalt alloy for different servo grades.

- Stacking Methods: Bonding, riveting, or laser welding ensure durability and uniform magnetism.

Technical Specifications

| Parameter | Specification |

| Material | Silicon Steel / Nickel Alloy / Cobalt Alloy |

| Lamination Thickness | 0.1–0.5 mm |

| Outer Diameter Range | 20–400 mm |

| Stack Height | Customized |

| Rotor Type | Slotted / Solid / Magnetic Insert |

| Processing Method | Progressive Stamping / Laser Cutting / Bonding |

| Application | Industrial Automation, Robotics, CNC Machines, Servo Drives |

Customization & OEM Service

- Tailor rotor diameter, pole number, and slot geometry according to customer drawings.

- Choose lamination materials and insulation coatings based on performance requirements.

- Select stacking method such as bonding, welding, or riveting to match application.

- Support for small-batch prototypes and full-scale mass production.

- Offer dynamic balancing and magnetic flux testing upon request.

- Provide OEM labeling, laser engraving, and custom export packaging for global brands.

Application Fields

- Industrial robots requiring fast-response torque control.

- CNC machinery with precise speed and position accuracy.

- Automation systems needing consistent servo reliability.

- Medical and laboratory equipment requiring low noise and vibration.

- Aerospace servo actuators designed for lightweight performance.

Production Process

Advanced Workshop