Stator and Rotor Lamination for Diesel Generator

- High Magnetic Efficiency: Optimized silicon steel sheets minimize eddy current loss.

- Dimensional Precision: Tight tolerances ensure stable magnetic flux distribution.

- Versatile Application: Suitable for DC & AC motors used in diesel generator systems.

- Custom Design: Support for compound, high-speed, and single-slot punching dies.

- Flexible Manufacturing: Different tonnage presses to meet specific generator models.

- Corrosion Protection: Insulation coatings (C3, C5, C6) ensure long-term durability.

Technical Specifications

| Parameter | Specification |

| Material | Silicon Steel Sheet |

| Outer Diameter (Stator) | Custom range (mm) |

| Outer Diameter (Rotor) | Custom range (mm) |

| Thickness per Lamination | 0.35–0.5 mm |

| Stack Height | Up to 400 mm |

| Punching Type | Compound / High-Speed / Single-Slot |

| Application | Diesel Generator Alternator |

| Certification | ISO9001, IATF16949 |

| Brand | OEM & ODM |

Customization & OEM/ODM Service

- Custom dimensions and punching die designs per generator model.

- OEM & ODM support with co-engineering and prototyping services.

- Quick mold development by the in-house R&D team.

- Compatible with AC/DC motor generators across industrial and commercial applications.

Application Fields

- Diesel generator sets for industrial facilities and construction sites.

- Backup power for hospitals, telecommunications, and data centers.

- Marine and transportation generator systems.

- Hydraulic power units and elevator backup systems.

- New energy hybrid systems using diesel-electric integration.

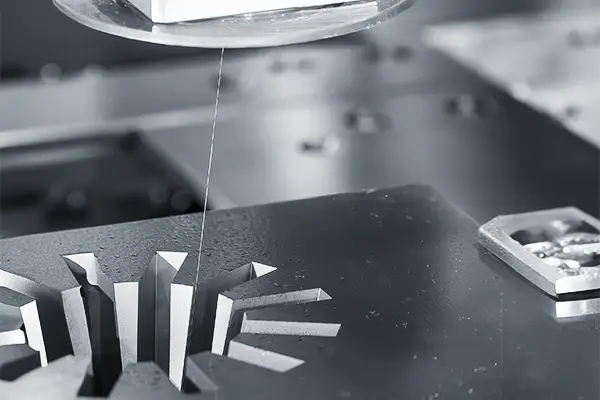

Production Process

Advanced Workshop