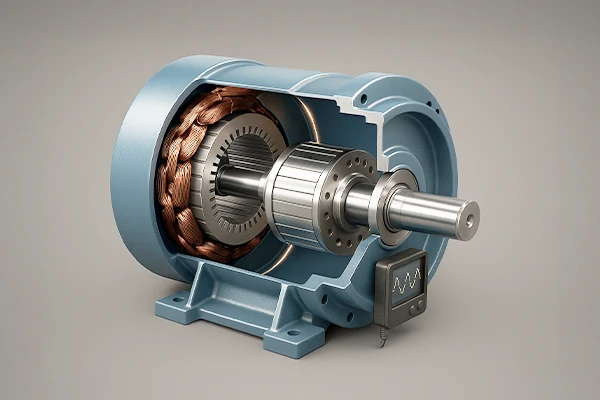

Generator Stator and Rotor

- We design and manufacture generator stators and rotors from prototype to volume, meeting your electrical targets, envelope, and duty cycle.

- From core stacks to fully wound assemblies, we optimize air gap concentricity, losses, insulation life, balance, and serviceability, with full support.

- Air-gap ≤0.05–0.10 mm TIR

- Multiple Generator Types Supported

- 4-week Complex-assembly Delivery

- Global Standards: ISO, IEC, IP Ratings

What We Can Customize

- From electromagnetic design to machining, we tailor cores, stators, rotors, and finishes for your performance, reliability, and certification goals.

- Electromagnetic Design: Optimize pole count, slot geometry, air-gap, winding scheme, saturation margin, and efficiency for your duty cycle and grid standards.

- Magnetic Core: Choose lamination grade, thickness, stacking factor, tooth/slot geometry, and core clamping to minimize eddy losses, vibration, and audible noise.

- Stator System: Specify insulation class, winding method, slot liners, impregnation resin, lead exits, and thermal paths to hit voltage, temperature rise, and EMI targets.

- Rotor System: Select squirrel-cage or PM rotor, pole shoes, skew, shaft alloy, damping, and balance grade for torque ripple, inertia, and environment.

- Machining & Finishing: Define tolerances, concentricity, runout, dynamic balancing, keyways, coatings, corrosion protection, and assembly fixtures to meet ISO, IEC, and OEM specifications.

Typical Technical Specifications

Reference ranges for generator stators and rotors covering electrical ratings, materials, geometry, balance, cooling, insulation, and typical tests.

| Parameter | Options | Notes |

| Phases & frequency | 1-phase or 3-phase; 50 Hz / 60 Hz or specified | Dual-frequency on request |

| Voltage & power | As specified (LV/MV) | Designed to required insulation class |

| Poles | 2–20+ | According to speed and grid requirements |

| Slot / pole | Optimized per waveform and losses | FEM-backed design available |

| Lamination | NOES/GOES and high-grade Si-steel; 0.35–0.50 mm typical | Alternate thicknesses on request |

| Stack height | Per rating | Step-stacking or interlock options |

| Stator winding | Random or formed coils; star/delta/series-parallel | Thermistor or RTD integration optional |

| Winding conductors | Copper or aluminum | Class F/H insulation systems |

| Lead exit | Terminal box, flying leads, or plugs | IP grade to requirement |

| Rotor type | Salient, non-salient, squirrel-cage, or PM | Skew and pole arc optimized |

| Rotor bars & rings | Cast aluminum, or copper bar with brazed rings | NDT on brazes available |

| Shaft | 40Cr/42CrMo or specified alloy | Journal and keyway per drawing |

| Skew | 0–1.5 slots typical | Reduces torque ripple and noise |

| Balance class | ISO 21940 Grade G2.5 (G1.0 on request) | Component and assembly balancing |

| Air-gap concentricity | ≤ 0.05–0.10 mm typical, per frame size | Verified with CMM or dial methods |

| Runout (TIR) | ≤ 0.02–0.04 mm on critical journals | As drawing |

| Cooling / enclosure | ODP/TEFC; ventilation ducts; fan or impeller | Custom fan geometry supported |

| Insulation system | Class F or H; VPI, trickle, or solventless | Partial-discharge–resistant options |

| Coatings | Anti-corrosion, anti-tracking, anti-rust | Salt-spray grade on request |

| Tests | Core-loss, surge, hi-pot, balance, overspeed | Full FAT available |

Types of Generators We Serve

We engineered stators and rotors tailored for AC, DC, synchronous, and induction generators across industrial, renewable, and grid-parallel applications worldwide.

AC Generator

- Low-loss laminated stators and dynamically balanced rotors maximize efficiency, maintain tight air-gap concentricity, reduce vibration, and ensure clean, stable AC output.

DC Generator

- Rigid stator frames and commutator-ready rotors provide steady DC voltage, longer brush life, precise concentricity, and dependable performance under heavy duty.

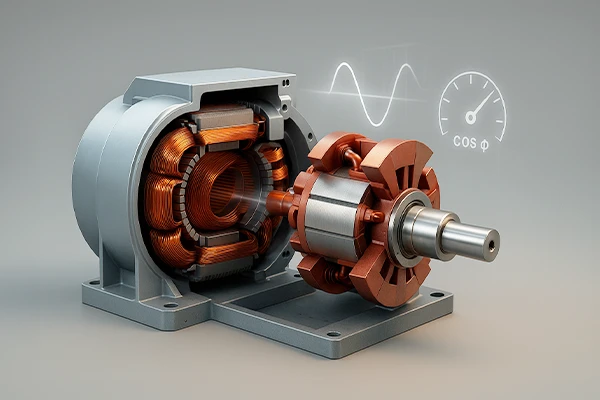

Synchronous Generator

- Precision-wound stators and accurate pole rotors deliver tight voltage regulation, strong power factor control, low harmonics, and reliable grid-parallel operation.

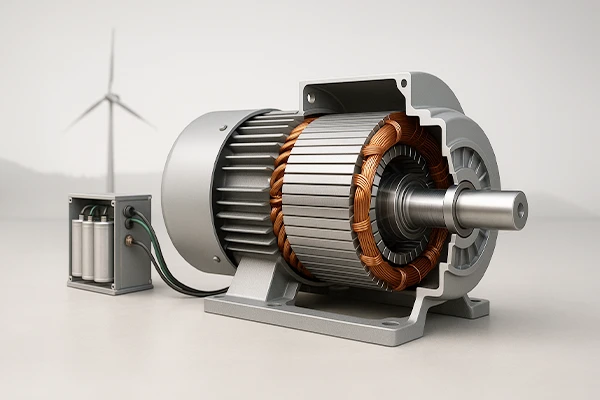

Induction Generator

- Optimized stator slots and robust squirrel-cage rotors yield high efficiency, minimal slip losses, easy capacitor excitation, and durable uptime for renewables.

Our Stator and Rotor Production Process

- Our generator stator and rotor manufacturing process ensures precision, durability, and consistent electrical performance through every production stage.

- Material Selection: Choose premium electrical steel and copper for optimal magnetic efficiency.

- Core Stamping: Precisely punch laminated sheets ensuring tight dimensional and concentric tolerances.

- Stacking & Clamping: Assemble core laminations under uniform pressure to maintain structural integrity.

- Winding Formation: Accurately coil insulated copper wires using automated tension-controlled winding machines.

- Insulation Treatment: Apply varnish impregnation for superior dielectric strength and heat resistance.

- Machining & Balancing: Perform precision turning, grinding, and balancing for vibration-free operation.

- Heat Treatment: Stabilize magnetic and mechanical properties through controlled temperature processes.

- Surface Coating: Protect against corrosion with high-durability epoxy or powder coating applications.

- Quality Inspection: Conduct dimensional, electrical, and dynamic tests ensuring compliance with design standards.

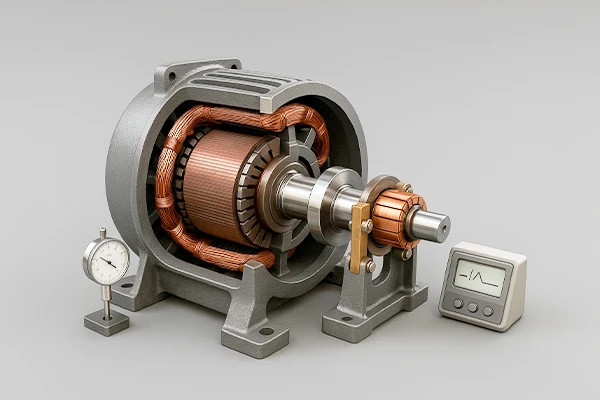

Quality & Testing

- Measured, traceable quality controls across geometry, electrical integrity, balance, vibration, and acoustics ensure every unit meets specification&safety.

- Air-gap Concentricity: Controlled via ID/OD datums; bore alignment checks and blue-fit verification.

- Runout & Fits: Bearing seats, keyways, and tapers held to drawing; critical features 100% gauged.

- Stack Integrity: Burr height, lamination count, interlock/weld audit; axial clamp force measured.

- Electrical Assurance: Hi-pot, surge, resistance, and inductance recorded per unit or per lot.

- Core Performance: Core-loss and insulation tests on stator cores; PD testing on request.

- Balance Proof: Residual unbalance and test speed reported; rotor serialized to certificate.

- Vibration & Acoustics: Vibration limits per spec; skew and fan design tuned for noise.

Customer Case

- A wind farm OEM needed high-efficiency generator stators and rotors meeting ISO balance G2.5, tight air-gap, and 3-month delivery deadline.

Our Solution

- Optimized lamination grade and 0.35 mm stack, revised slot geometry, and controlled skew to reduce core loss and torque ripple.

- Class H, VPI-impregnated windings with improved thermal paths; lead exits and insulation scheme tailored to duty cycle.

- Precision machining with ID/OD datum alignment, blue-fit checks, and runout control for tight air-gap concentricity.

- Dynamic balancing to ISO 21940 G2.5 with serialized rotor certificates; 100% electrical tests (core-loss, surge, hi-pot, inductance).

Results

Metric | Result |

Air-gap concentricity (TIR) | ≤ 0.03 mm |

Residual unbalance | ISO 21940 G2.5 achieved at test speed |

Efficiency | +1.6 percentage points vs previous design |

Core loss (1.5 T, 50 Hz) | −8.5% |

Bearing vibration | −25% vs prior units |

Delivery | 12 weeks (within 3-month deadline) |

First-pass yield | 99.2% across the lot |

General FAQs

Which generator types do your stators and rotors support?

Able to manufacture for synchronous AC, induction, permanent-magnet, and DC generators across industrial, marine, renewable, and standby applications, matching required standards globally.

What materials do you use for generator stator and rotor manufacturing?

Materials include NOES laminations, copper or aluminum conductors, alloy shafts, and insulation systems ranked Class F or H for temperature rise compliance.

How do you reduce core losses in a generator stator?

Core loss minimized through lamination grade selection, thickness optimization, proper stacking factor, insulation coating, and stress-relief after machining, punching, welding, or clamping.

What quality systems govern your Generator Stator and Rotor production?

Quality control uses PPAP or APQP plans, incoming inspections, in-process controls, final audits, and SPC; certificates of conformity and test records supplied.

How do you package a Generator Stator and Rotor to prevent transit damage?

Packaging engineered for transport risks: anti-rust protection, foam blocking, bolt-downs, shock indicators, and moisture barriers; reusable crates available on request for shipments.