Electric motors and generators in vehicles, machines, appliances, and turbines all depend on one key part: the motor core. Though often unseen, its design greatly affects efficiency, torque, heat control, and noise.

As electrification grows in energy, transport, and industry, the need for high-performance motors is rising fast. This highlights how important good motor core design is for improving function, cutting energy loss, and supporting sustainability.

This article explains the motor core’s role, its types, and why precise design is critical in modern motors and generators.

The Role of the Motor Core in Electric Motors and Generators

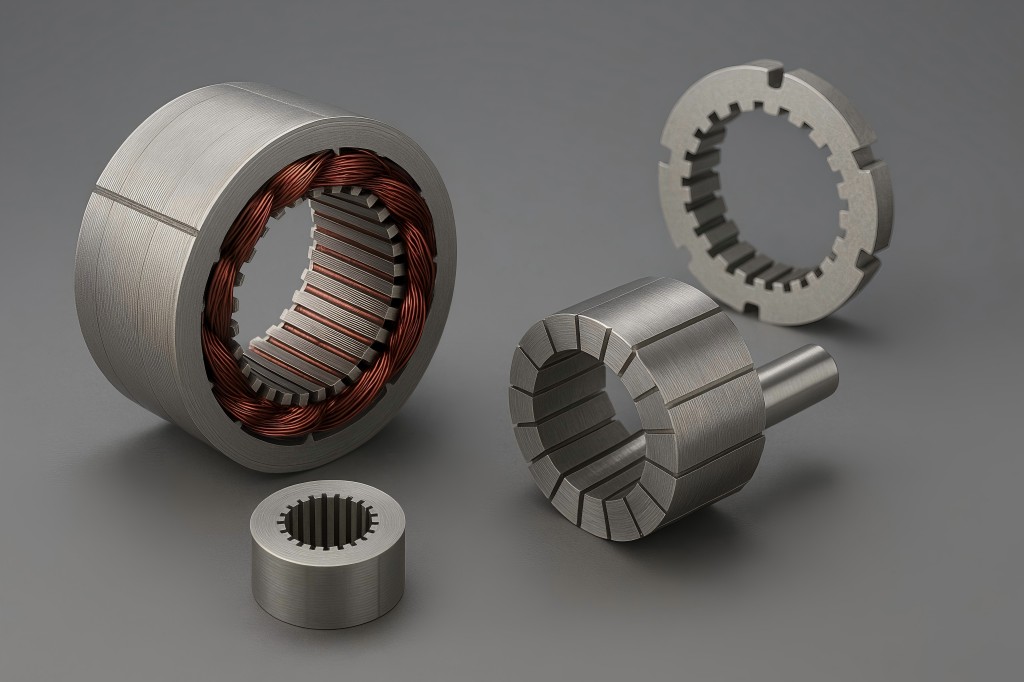

The motor core is the magnetic heart of an electric machine. The stator and rotor cores of electric motors or generating machines are made of laminated sheets of electrical steel that have been either laser-cut or stamped and stacked. These components form the foundation upon which magnetic fields are generated, transformed, and directed to create rotational or electrical energy.

Magnetic Flux Pathway

For magnetic flux, the motor core offers a low-reluctance channel. When current flows through the motor windings, magnetic fields are induced, and the motor core directs this magnetic flux efficiently between the stator and rotor. Without an optimized path, the magnetic circuit would suffer losses and reduced performance.

Heat Dissipation and Loss Minimization

Electrical steel laminations help reduce eddy current losses through insulation and fine layering. Proper core design minimizes hysteresis losses and facilitates better thermal management, both critical for maintaining energy efficiency and preventing overheating during operation.

Mechanical Strength and Shape Integrity

The motor core ensures dimensional stability during high-speed rotations, temperature variations, and electromagnetic stresses. Its geometric configuration also impacts torque generation and cogging behavior, influencing how smoothly a motor or generator operates.

Core Loss Management

Core losses—including eddy current and hysteresis losses—are the primary energy-wasting elements inside electric motors and generators. Careful core design, such as using high-grade non-oriented silicon steel and minimizing lamination thickness, significantly reduces these losses.

Types of Motor Cores

Motor core types can be classified in several ways, including by configuration (stator vs rotor), motor type (AC vs DC), and by construction methods (wound vs coreless). Knowing each category shows how the core design can be modified to meet the needs of different applications.

A. By Configuration

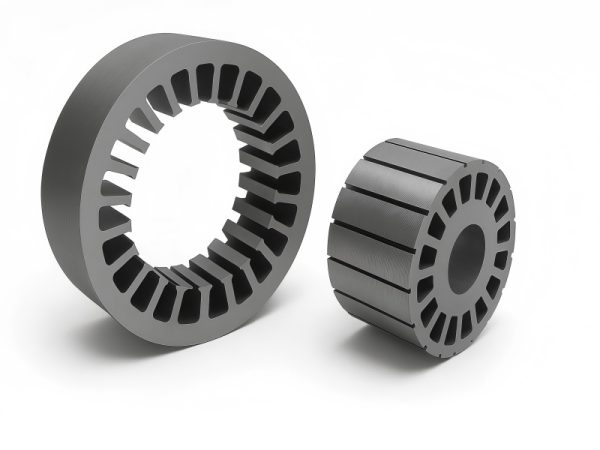

Stator Core

The stator core is the stationary component housing the armature windings. It’s where alternating current generates a rotating magnetic field, which then induces torque in the rotor. Stator cores require highly precise slot geometry and insulation to maximize efficiency and durability.

Rotor Core

The rotor core is the rotating counterpart. It can be constructed in squirrel cage form for induction motors or have permanent magnets or windings for synchronous and brushless motors. Rotor core lamination must withstand centrifugal force while maintaining a strong magnetic response.

B. By Motor Type

AC Motor Cores

- Induction Motors: Use laminated rotor cores (typically squirrel cage) and slotted stator cores. Efficiency improvements focus on core geometry, skewing, and lamination materials.

- Synchronous Motors: Include permanent magnet (PMSM) or wound-field rotors. High flux densities require advanced lamination stacking and bonding methods.

DC Motor Cores

- Brushed DC Motors: Feature slotted stators and wound armatures.

- Brushless DC Motors (BLDC): Employ laminated stators with precision slot design and rotors with embedded magnets. Their performance is heavily reliant on tight core tolerances.

C. By Core Design and Manufacturing Method

Slotted vs Slotless Cores

- Slotted Cores: Common in most industrial motors; provide better mechanical anchoring of coils but can introduce torque ripple.

- Slotless Cores: Reduce cogging torque and are often used in precision applications like robotics or medical devices.

Segmented Cores

Segmented stator cores use separate teeth and yoke segments to allow for automated winding, improved cooling, and modular production. They support compact motor architectures, especially in electric vehicles and aerospace.

Coreless Motors

Coreless motors save weight and remove core losses by doing away with the iron core in the rotor or stator. These are ideal for lightweight, low-inertia applications, such as drones or small medical tools.

Hairpin and I-Pin Wound Cores

These designs incorporate flat or rectangular wires into the core slots for higher slot fill factor and better thermal performance. Hairpin winding is popular in EV traction motors due to its efficiency and high-speed capability.

Importance of Material Selection and Manufacturing in Motor Core Design

The properties of the motor core depend significantly on material choice and fabrication processes. Here’s how each aspect affects performance:

A. Electrical Steel Grades

Motor cores are typically made of non-oriented silicon steel (NOES) for AC machines, and high-permeability materials for specific high-frequency uses. Lower core losses are achieved by using thinner laminations (0.1–0.35 mm) and high-silicon content (3% Si typical).

Advanced materials like cobalt alloys, amorphous metals, and grain-oriented steel (in specialized applications) further reduce losses and enhance saturation limits.

B. Insulation Coating

Each lamination is coated with an insulating layer to prevent inter-laminar eddy currents. Electrical insulation is maintained by modern coatings that are made to withstand mechanical stress and thermal aging.

C. Lamination Stacking Techniques

- Interlocking/Notching: Mechanical methods to align laminations.

- Laser Welding/Bonding: Offers superior rigidity and magnetic continuity, ideal for high-speed motors.

- Glue Bonding: Reduces vibration and noise.

Precision stacking directly influences vibration, acoustic noise, and magnetic alignment.

D. Stamping vs Laser Cutting

- Stamping: Cost-effective for mass production; uses carbide or tungsten-steel dies.

- Laser Cutting: Ideal for prototyping and special alloys; reduces burrs and maintains high dimensional precision.

Benefits of Using Well-Designed Motor Cores in Electric Motors and Generators

Optimized motor core design offers measurable advantages that ripple across performance, manufacturing efficiency, and long-term cost savings.

Improved Energy Efficiency

The total effectiveness of the system can be greatly increased by lowering core losses. With motors accounting for over 45% of global electricity consumption, energy savings through improved cores have massive sustainability implications.

Enhanced Torque and Power Density

High-quality lamination design and advanced winding configurations allow motors to generate more torque in smaller volumes, critical for EVs, robotics, and drones.

Lower Heat Generation

Minimized eddy currents and improved thermal conductivity prevent overheating, reducing the need for auxiliary cooling systems and increasing motor lifespan.

Reduced Noise and Vibration

Accurate lamination stacking and high-quality bonding reduce magnetic noise and mechanical resonance—especially vital for applications like home appliances, medical equipment, and precision manufacturing.

Extended Lifespan and Reliability

Better thermal performance, mechanical integrity, and magnetic behavior reduce wear on insulation, bearings, and windings—leading to less maintenance and downtime.

Greater Customization and Scalability

Segmented or modular motor cores allow for design flexibility and easier scaling across various voltage and power requirements without redesigning the entire motor.

Compliance with Efficiency Standards

Standards such as IE3, IE4 (IEC), and NEMA Premium demand motors to exceed specific energy benchmarks. Achieving these standards is often only possible with optimized core materials and designs.

Case Studies and Applications

Electric Vehicles (EVs)

Modern EVs use permanent magnet synchronous motors (PMSM) with hairpin-wound stators and skewed rotor cores to reduce torque ripple. Tesla, BYD, and other OEMs rely heavily on core design to improve range and reduce battery load.

Industrial Automation

Servo motors and linear actuators require ultra-precise core alignment. Coreless or segmented designs with laser-welded laminations deliver silent, smooth, and fast motion for robotic arms and CNC machinery.

Wind and Hydroelectric Generators

High-output generators use massive stator and rotor cores designed for low hysteresis and excellent thermal properties. Bonded laminations and robotic stacking help ensure consistency across large-scale installations.

Home Appliances

Appliances like washing machines and refrigerators benefit from slotless or compact motors with optimized stator designs to reduce noise, vibration, and energy consumption.

The Future of Motor Core Innovation

3D Printing of Soft Magnetic Materials

Additive manufacturing is emerging as a method to produce complex core shapes and integrate cooling channels, impossible with traditional laminations.

High-Frequency and Axial Flux Motors

As industries shift toward high-frequency operation (especially in drones and aerospace), thinner laminations and novel configurations like axial flux cores are becoming standard.

AI-Driven Design Optimization

Machine learning and finite element analysis (FEA) are being used to model magnetic field behavior and thermal profiles to refine core geometry for targeted performance outcomes.

Sustainable Materials and Recycling

Recyclability of motor cores is growing in importance. Laminations made from recyclable silicon steel and magnet-free rotor designs are gaining traction to support circular economy goals.