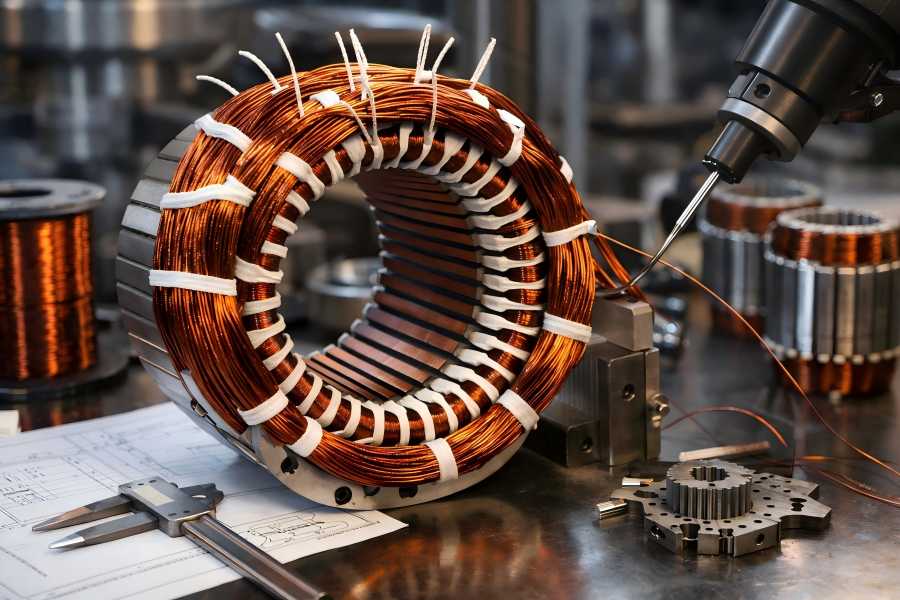

Electric motor performance and overall efficiency are largely dependent on the stator slot fill factor. By optimizing this factor, manufacturers can improve the motor’s copper utilization, reduce losses, and enhance thermal performance. However, achieving the ideal fill factor requires careful attention to design, manufacturing processes, and material selection.

Understanding Slot Fill Factor

The slot fill factor refers to the percentage of the total slot volume that is occupied by the conducting material (typically copper) compared to the total volume available in the stator slots. A higher slot fill factor means more copper is packed into the stator slots, which improves the motor’s power density and reduces the total copper losses during operation.

The slot fill factor can be computed using this formula:

Slot Fill Factor = (Volume of Copper in Slot/Total Volume of Slot)*100

Motor manufacturers aim for a high slot fill factor to improve efficiency and torque density. However, excessively high fill factors can hinder heat dissipation and mechanical strength, affecting long-term reliability.

Use High-Quality, Thin Insulation Materials

Insulation materials greatly affect the slot fill factor. Thicker insulations, while providing electrical isolation, reduce space for copper conductors. Using thinner, high-quality insulation materials increases the available copper area within the stator slots.

Modern insulation materials, such as advanced polymer films, are not only thinner but also provide better thermal resistance and electrical insulation. This reduction in insulation thickness allows for a higher packing density of copper conductors. Additionally, thin insulations are more flexible, allowing for precise coil winding techniques that further optimize slot fill.

However, it is essential to balance insulation thickness with the reliability of the motor. Thicker insulation may still be necessary for certain applications that involve high voltages or harsh environments, making careful material selection essential.

Select Optimal Wire and Conductor Shapes

One effective way to improve the stator slot fill factor is by selecting optimal wire shapes. While round wires are easy to manufacture, non-circular shapes like rectangular or sector conductors can better utilize slot space, increasing packing density. These shapes reduce air gaps between windings, improving efficiency and lowering resistance.

Although non-circular conductors enhance performance, they complicate manufacturing, requiring precise winding machines. However, the efficiency gains often justify the added complexity.

| Wire Shape | Slot Fill Factor | Pros | Cons |

| Round Wire | 60-70% | Easy to manufacture, less costly | Lower packing density |

| Rectangular | 75-85% | Higher fill, better space utilization | More complex manufacturing |

| Sector Shaped | 80-90% | Maximize copper use, better efficiency | More complex winding |

Implement Advanced Winding Techniques

The way the coils are wound plays a crucial role in achieving an optimal slot fill factor. Traditional winding techniques, such as lap and wave winding, can be improved by employing advanced methods like distributed windings, concentrated windings, and hairpin windings.

- Distributed Windings: This technique spreads coils across multiple slots, ensuring even magnetic field distribution and reducing eddy current losses. However, it generally results in a lower slot fill factor compared to concentrated windings.

- Concentrated Windings: Coils are grouped in a single slot, optimizing space and increasing the slot fill factor, which improves motor efficiency. However, it can cause higher harmonic distortion and thermal stress, affecting reliability.

- Hairpin Windings: Wire segments are bent into a U-shape and inserted into stator slots, maximizing space utilization and reducing the number of turns. This method increases the slot fill factor and current density, boosting motor performance.

By adopting advanced winding techniques, manufacturers can significantly optimize the stator slot fill factor while also improving motor performance, torque, and overall efficiency.

| Winding Technique | Fill Factor Increase | Pros | Cons |

| Distributed Winding | 10-15% | Even magnetic field distribution | Lower fill factor |

| Concentrated Winding | 20-30% | Higher slot fill, higher efficiency | Higher harmonic distortion |

| Hairpin Winding | 15-20% | High copper utilization, compact |

Optimize Slot Geometry

The geometry of the stator slots is another critical factor in determining the achievable slot fill factor. Slot shapes and dimensions, including the depth, width, and overall design of the slots, influence the amount of copper that can be inserted into the stator.

Slot designs that are too narrow or shallow may limit the amount of conductor material that can be accommodated, reducing the fill factor. Conversely, overly large slots may result in wasted space and inefficient use of copper, thereby diminishing motor efficiency.

Optimizing slot geometry maximizes copper volume while maintaining stator integrity. Engineers use FEA and CFD to refine slot shapes and sizes, assessing their impact on performance, heat dissipation, and costs.

Improve Coil Insertion Processes

Coil insertion is crucial for the stator slot fill factor. Inaccurate or inefficient insertion can lead to poor packing density, wasting copper space, and reducing motor performance.

Modern automated insertion systems use robotic arms and coil handling equipment to place coils accurately, minimizing damage, deformation and ensuring proper positioning. These systems enable faster, more consistent insertion, reducing human error and improving slot fill accuracy.

Additionally, the use of slot liners or coil insertion aids can further enhance the slot fill factor by providing additional support for the coils and ensuring that they remain in place during the winding and insertion processes.

Use Pre-Formed Coils When Applicable

Pre-formed coils offer another method for improving the stator slot fill factor. Pre-formed coils are manufactured off-site, often under controlled conditions, and then inserted directly into the stator slots during assembly. This process ensures consistent coil shape and size, reducing the likelihood of deformation or damage that can occur during on-site coil forming.

Pre-formed coils also provide more precise control over the slot fill factor, as they are designed to fit the stator slots perfectly. By eliminating the need for on-site coil formation, this method reduces the potential for errors and provides a more reliable method for achieving optimal fill factors.

However, the use of pre-formed coils comes with higher initial costs due to the additional manufacturing steps required. As such, it is more suitable for high-volume production runs where the benefits of consistency and efficiency outweigh the additional investment.

Employ Vacuum Impregnation & Resin Filling

Vacuum impregnation is a widely used process for enhancing the mechanical and thermal performance of motor stators. This technique involves impregnating the stator windings with a resin material under vacuum conditions, ensuring that the resin fills all the voids within the windings and slots.

This process not only increases the slot fill factor but also improves the thermal conductivity and mechanical strength of the stator, reducing the likelihood of coil degradation under high temperature and load conditions. Vacuum impregnation helps to improve the overall reliability and lifespan of the motor, making it particularly beneficial for high-performance applications.

Furthermore, resin filling helps to reduce vibration and mechanical noise, improving motor performance and efficiency. However, the vacuum impregnation process requires specialized equipment and careful control of the resin curing process, making it a more complex and costly option compared to other methods.

Quality Control & Inspection Technologies

Effective quality control ensures stator slots meet specifications. Advanced imaging techniques like X-ray, ultrasound, and 3D scanning measure the slot fill factor and detect gaps or irregularities in coil placement.

By employing real-time monitoring during the winding and insertion processes, manufacturers can adjust the parameters to ensure optimal slot fill. Automated inspection systems can also help detect defects in the coils, ensuring that only high-quality products make it to the final assembly stage.

These technologies enable manufacturers to achieve high precision and consistency, resulting in motors with improved performance and efficiency.